Multi-strand special conductor stranding process of numerical control cage type stranding machine

A cage-type stranding machine and stranding technology, applied in the direction of cable/conductor manufacturing, used to reduce the size of conductor/cable, and used to manufacture conductive/semiconductive layer equipment, etc., can solve the cracking of plastic protective layer , flashover faults, cable grounding faults and other problems, to achieve the effect of not easy to crack, improve tensile performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Such as Figure 1-2 Shown, embodiment one of the present invention is:

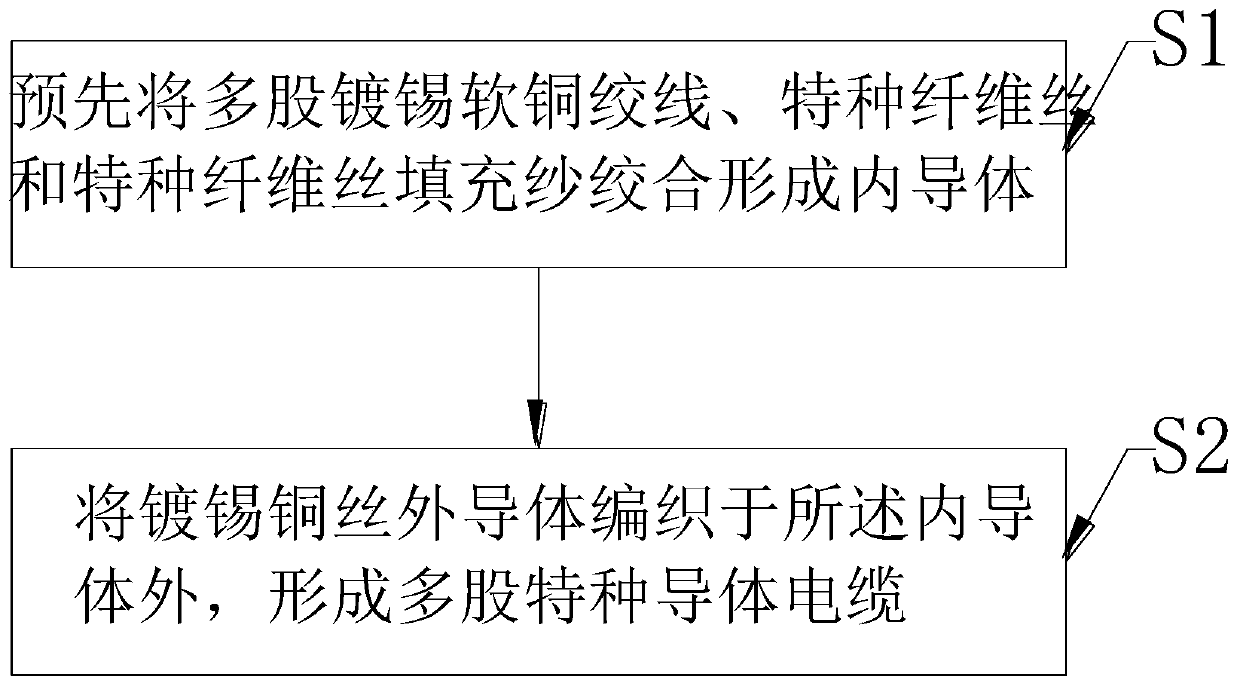

[0031] A numerically controlled cage type stranding machine multi-strand special conductor stranding process, comprising the following steps:

[0032] S1. Twisting multiple tinned annealed copper strands, special fiber filaments and special fiber filament filling yarns in advance to form an inner conductor;

[0033] S2. Weaving the tinned copper wire outer conductor outside the inner conductor to form a multi-strand special conductor cable;

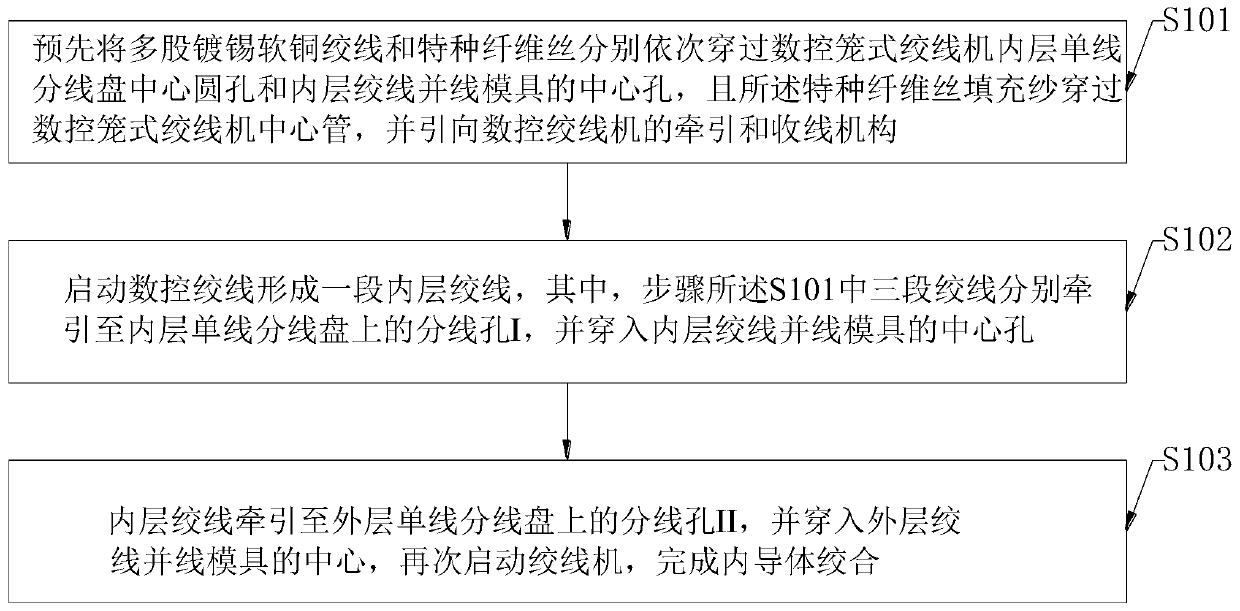

[0034] Wherein, said twisting to form the inner conductor comprises the following steps:

[0035] S101. Pass the multi-strand tinned annealed copper stranded wire and the special fiber wire through the central hole of the inner layer single wire distribution plate and the center hole of the inner layer stranded wire paralleling mold in sequence respectively in advance, and the The special fiber filament filled yarn passes through the central tube of the CNC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com