Erection method and erection system of overhead conductor considering creep quantity

An overhead wire and wire technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inability to meet safe operation, difficulty in estimating wire elongation, and excessive sag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

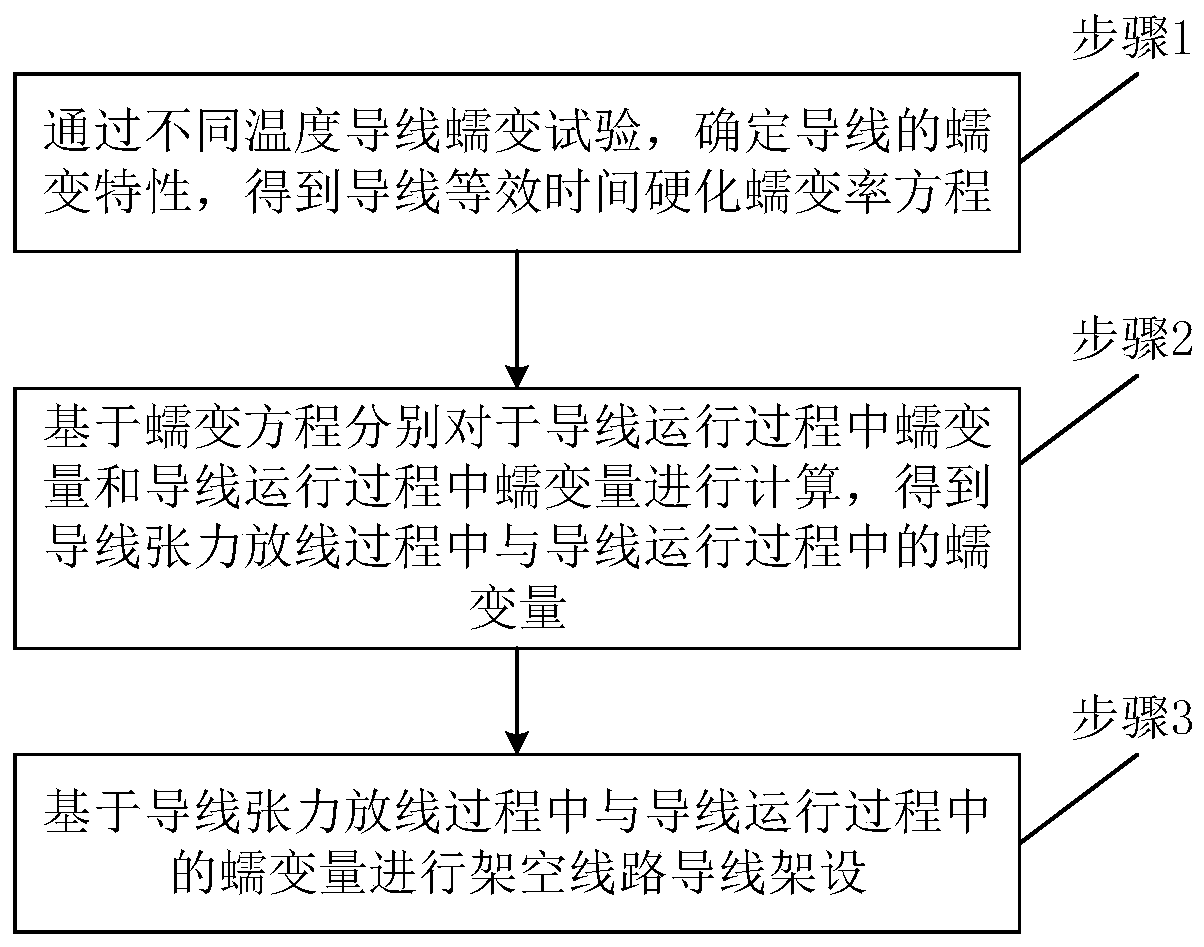

[0055] A schematic flow chart of an overhead conductor erection method considering creep provided by the present invention is as follows figure 1 shown, including:

[0056] Step 1: Determine the creep characteristics of the wire through the wire creep test at different temperatures, and obtain the equivalent time hardening creep rate equation of the wire;

[0057] Step 2: Based on the creep equation, calculate the creep amount during the running process of the wire and the creep amount during the running process of the wire, and obtain the creep amount during the wire tension unwinding process and the wire running process;

[0058] Step 3: Conduct overhead line conductor erection based on the creep value during conductor tension pay-off and conductor running.

[0059] Specifically, the erection methods of overhead conductors considering creep include:

[0060] Step 101: Determining the size a of the creep amount per unit time and the slope b of the creep rate equation in log...

Embodiment 2

[0108] Firstly, the creep characteristics of the wire are determined by creep test. Set the test temperature as 20°C, 40°C and 60°C respectively, and the plus or minus error shall not exceed 2°C; according to the material and cross section of the wire, check the table to determine the wire breaking force RTS; select 25% and multiply the wire breaking force RTS to get Test the tension and keep it constant; measure the creep (deformation) elongation of the wire under 3 temperature conditions within 1000 hours, and sample a set of data every 2 hours; the creep ε is a function of the creep time t, determined by the creep rate Equation ε = a t b Determined, where ε represents the elongation of the wire per unit time due to creep, a represents the size of the creep amount per unit time, and b represents the slope of the creep rate equation in double-logarithmic coordinates, representing the speed of creep with time , t represents the duration of creep of the wire; taking the logari...

Embodiment 3

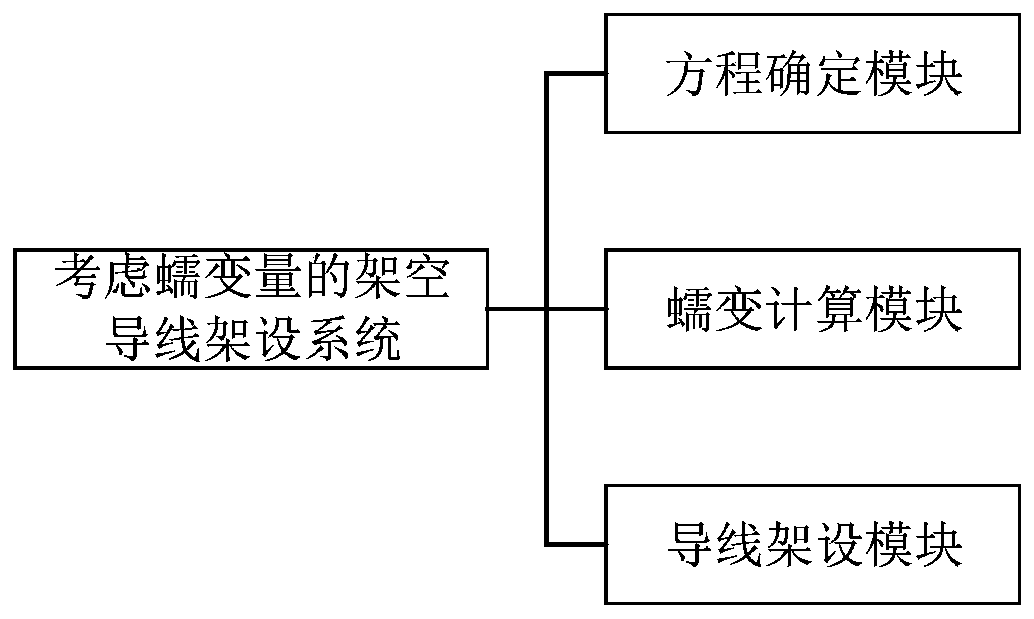

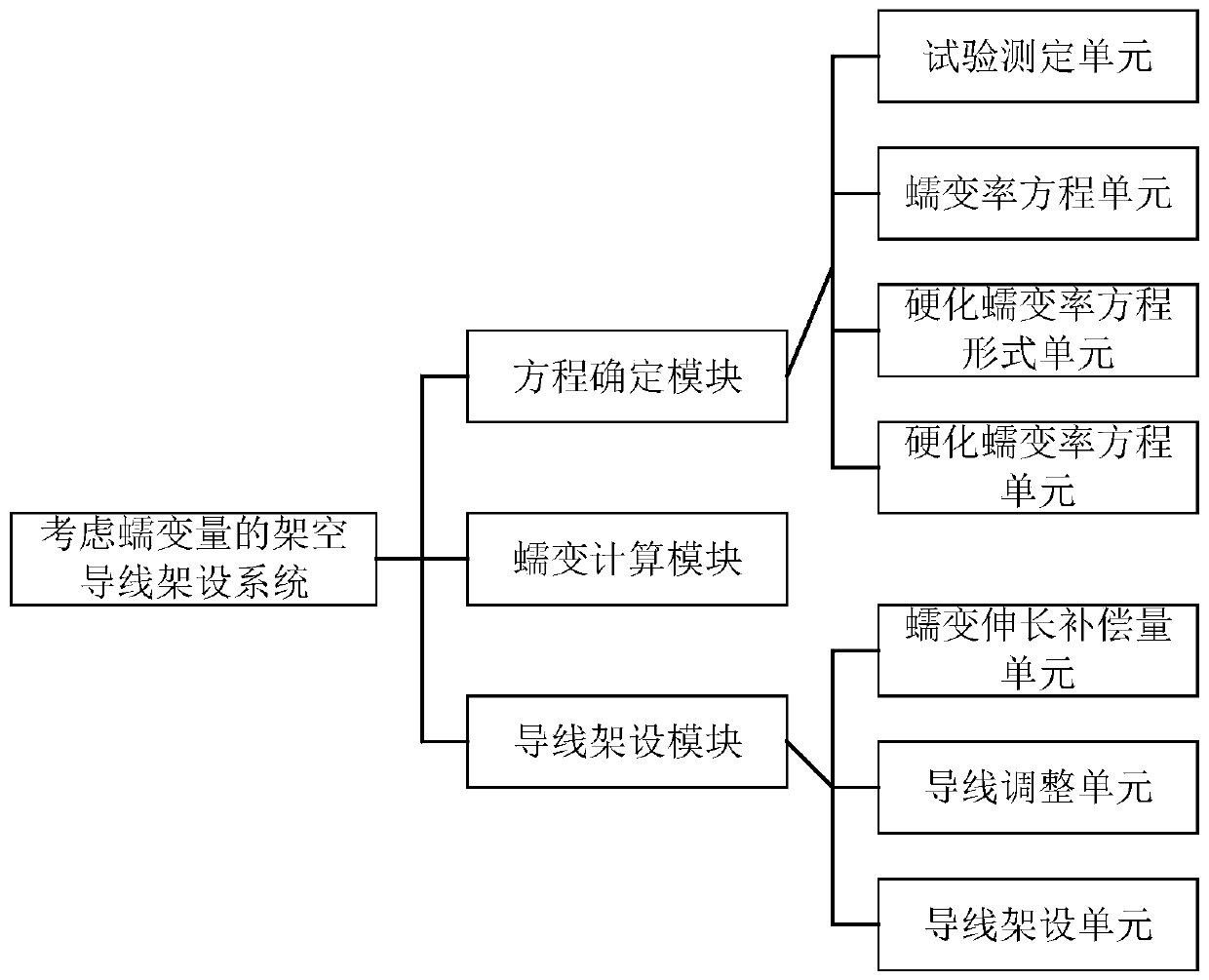

[0111] Based on the same inventive concept, the present invention also provides an overhead conductor erection system considering creep. Since the principle of solving technical problems of these devices is similar to the overhead conductor erection method considering creep, the repetition will not be repeated.

[0112] The basic structure of the system is as figure 2 As shown, including: equation determination module, creep calculation module and conductor erection module;

[0113] Among them, the equation determination module is used to determine the creep characteristics of the wire through different temperature wire creep tests, and obtain the equivalent time hardening creep rate equation of the wire;

[0114] The creep calculation module is used to calculate the creep amount during the running process of the wire and the creep amount during the running process of the wire based on the creep equation, and obtain the creep amount during the wire tension unwinding process a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com