Common-mode voltage suppression system

A common-mode voltage and common-mode capacitor technology, applied in the field of common-mode voltage suppression system, can solve the problems of three-phase four-wire or three-phase five-wire power supply, AC and DC side common-mode interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

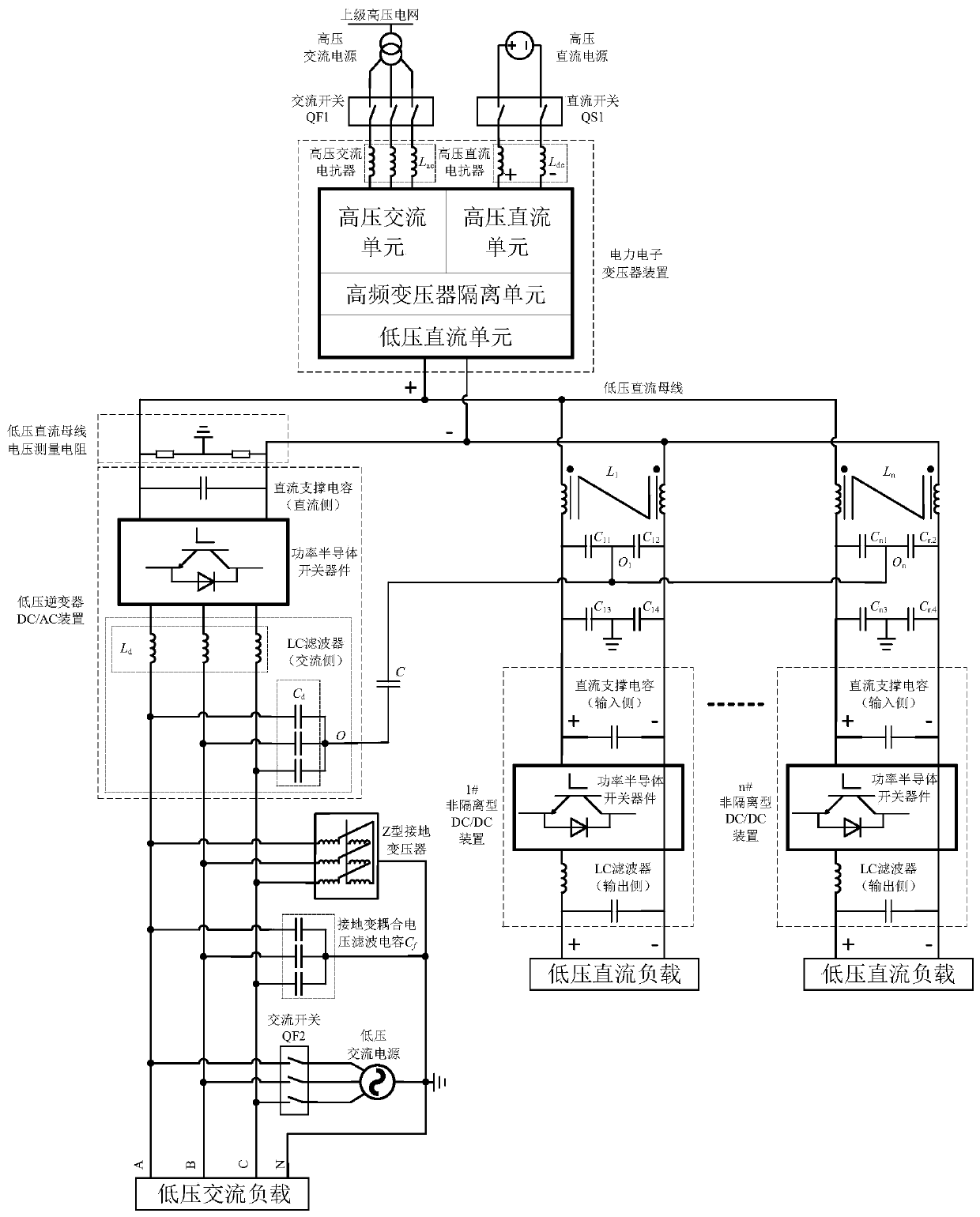

[0062] This embodiment provides a common-mode voltage suppression system, a schematic diagram of the common-mode voltage suppression system, as shown in figure 1 As shown, it usually consists of a power electronic transformer device, an inverter DC / AC device and a DC / DC device.

[0063] The power electronic transformer device in the figure usually consists of a high-voltage AC unit, a high-voltage DC unit, a high-frequency transformer isolation unit, a low-voltage DC unit, and a high-voltage AC reactor L ac , HVDC smoothing reactor L dc and other components; the power electronic transformer passes through the reactor L ac , The AC switch QF1 is connected to the high-voltage AC power supply, and through the smoothing reactor L dc1. The DC switch QS1 is connected to the high-voltage DC power supply; the low-voltage DC unit is connected to the low-voltage DC bus. The power electronic transformer is responsible for the transformation of the voltage level and the transformation ...

Embodiment 2

[0069] This embodiment provides a common-mode voltage suppression system, the system comprising:

[0070] Power electronic transformers, low-voltage DC buses, low-voltage inverter DC / AC devices and non-isolated DC / DC devices;

[0071] The input end of the power electronic transformer is connected to the medium and high voltage grid, and the output end is connected to the low-voltage DC bus;

[0072] The input end of the low-voltage inverter DC / AC device is connected to the low-voltage DC bus, and the output end is connected to a low-voltage AC load;

[0073] The input end of the non-isolated DC / DC device is connected to the low-voltage DC bus in parallel, and the output ends are respectively connected to the low-voltage DC load;

[0074] The output side of the low-voltage inverter DC / AC device is connected to the input side of the non-isolated DC / DC device to form a low-impedance loop of common-mode voltage;

[0075] The medium and high voltage power grid is a DC medium and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com