Seeder for agricultural planting

A seeder and agricultural technology, applied in the field of agricultural machinery, achieves the effects of good seeding effect, novel design and convenient discharge of seeding rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

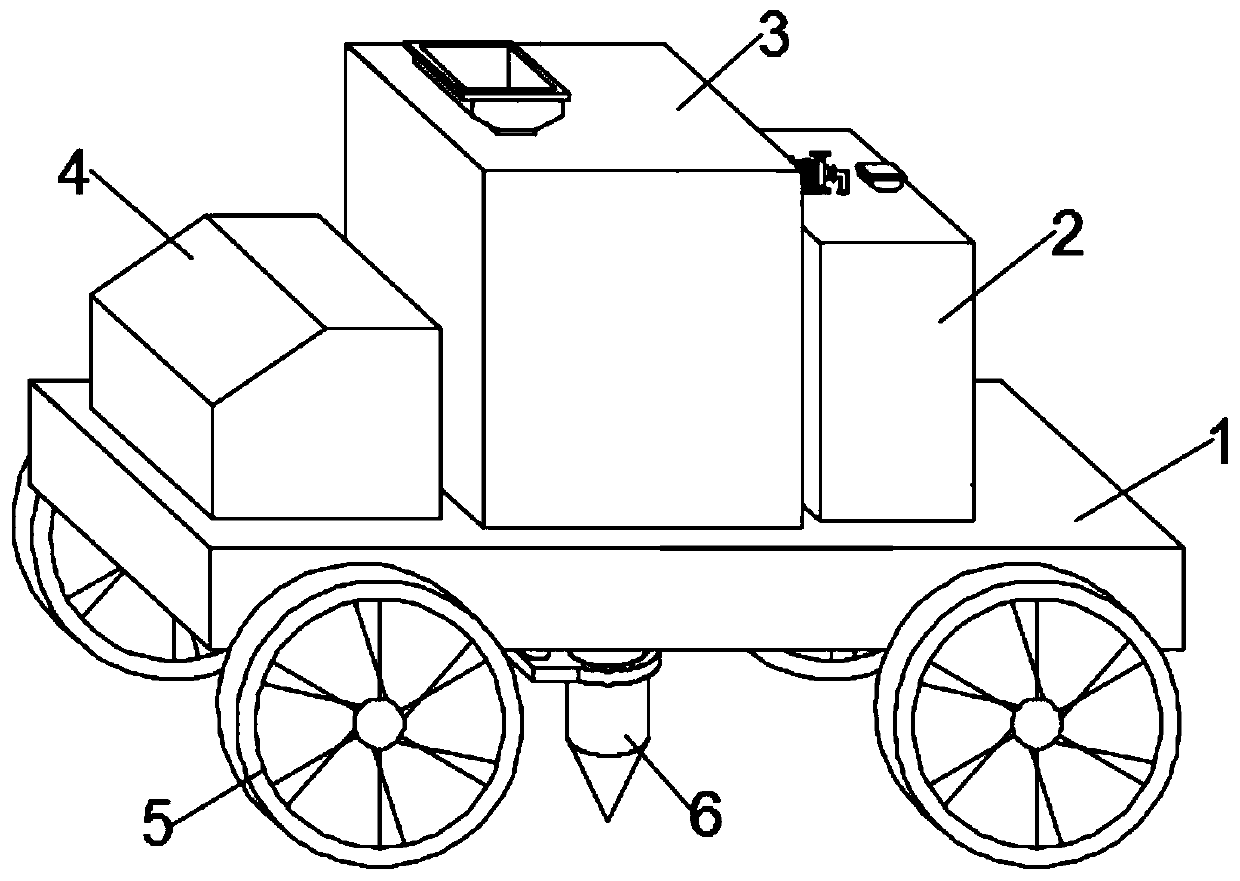

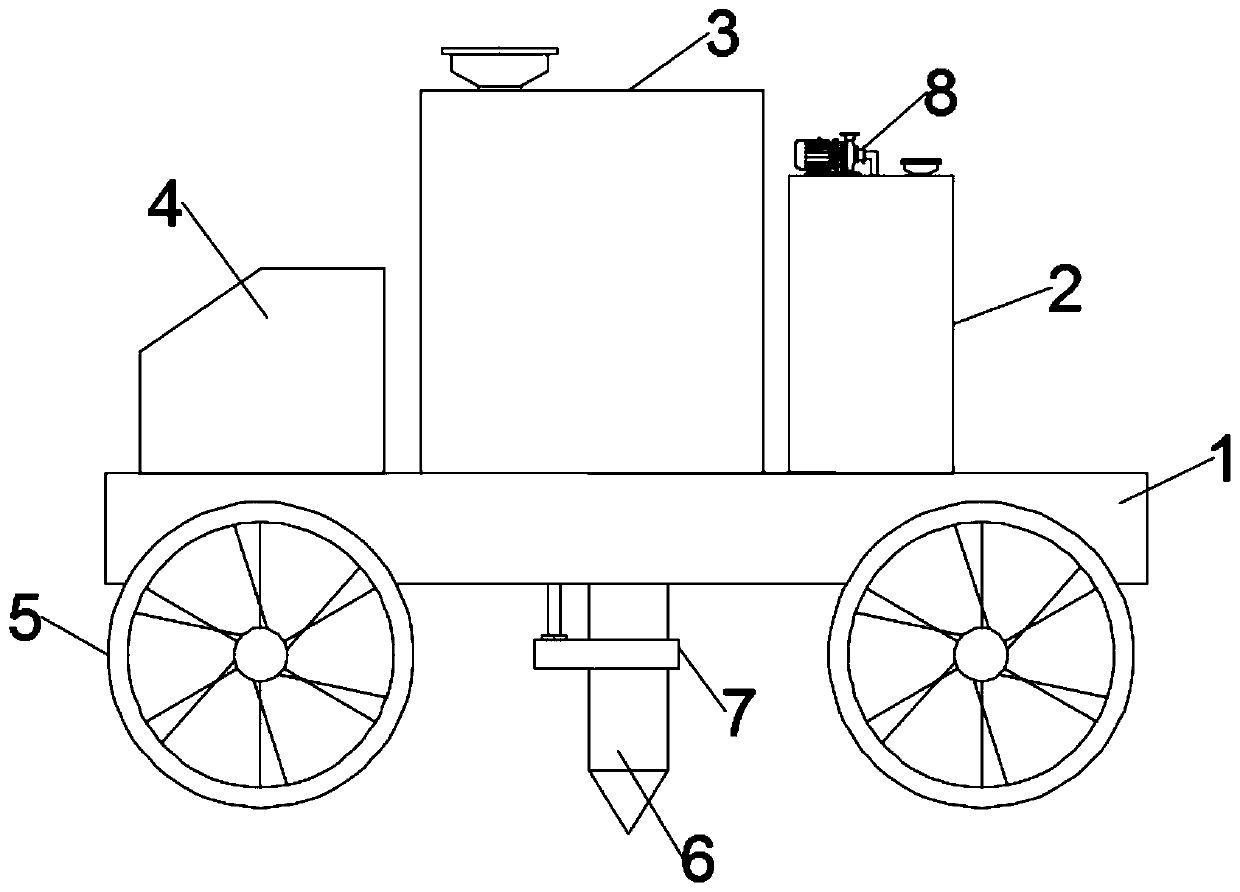

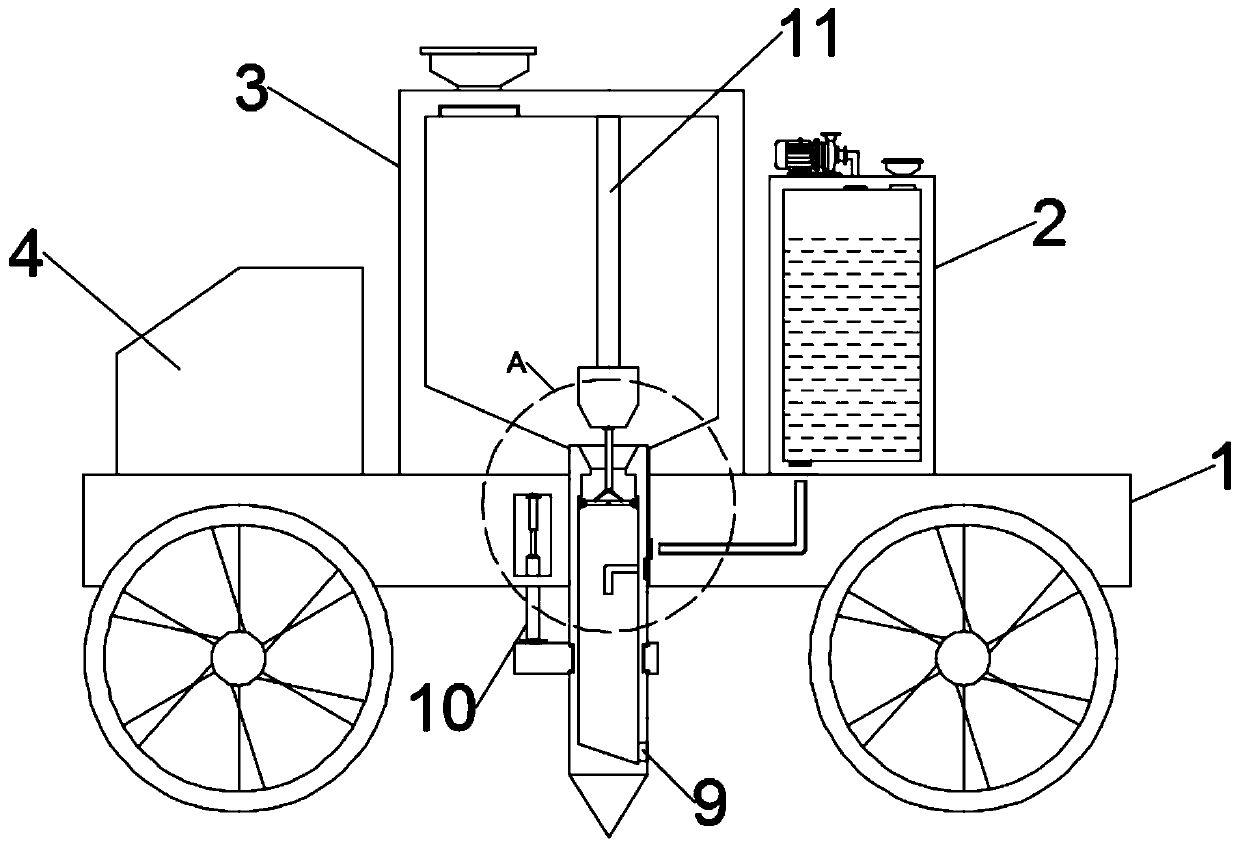

[0023] see Figure 1~4 , in the embodiment of the present invention, a kind of seeder for agricultural planting, comprises base plate 1; The lower end of described base plate 1 is equipped with roller 5, thereby facilitates the movement of this device, and the upper end of described base plate 1 is equipped with material storage box 3, And the bottom plate 1 at the bottom of the material storage box 3 runs through at least one sowing rod 6 driven by the drive assembly to move up and down, the upper end of the sowing rod 6 penetrates the bottom of the material storage box 3 and extends into the inside of the material storage box 3, A buffer cavity is provided at the upper end of the inner side of the sowing rod 6, and the buffer cavity is in two different states according to the position of the sowing rod 6, one of which is: the sowing rod 6 moves up, and the buffer cavity The upper end is closed, the lower end is opened, and the second is: the seeding rod 6 moves down, the upp...

Embodiment 2

[0033] see Figure 5 , the present invention also proposes another embodiment to control the up and down movement of the seeding rod 6 during the specific implementation process. Specifically, the drive assembly includes a motor 19 and a turntable 20, and the output shaft of the motor 19 is connected to the turntable 20 through a transmission belt. The rotation shaft of the rotating disk 20 is connected in rotation, and the eccentric position of the turntable 20 is connected in rotation with one end of the third connecting rod 21. The fixed plate 7 on the 6 is connected, and the motor 19 drives the rotating disk 20 to rotate. When the rotating disk 20 rotates, the reciprocating up and down movement of the sowing rod 6 is realized by the effect of the third connecting rod 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com