Implementation method and manufacturing apparatus of multifunctional ultra-micro bubble water

A technique for ultrafine bubbles, implementing methods, applied in the directions of mixing methods, chemical instruments and methods, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the present invention, the following examples are given to illustrate it.

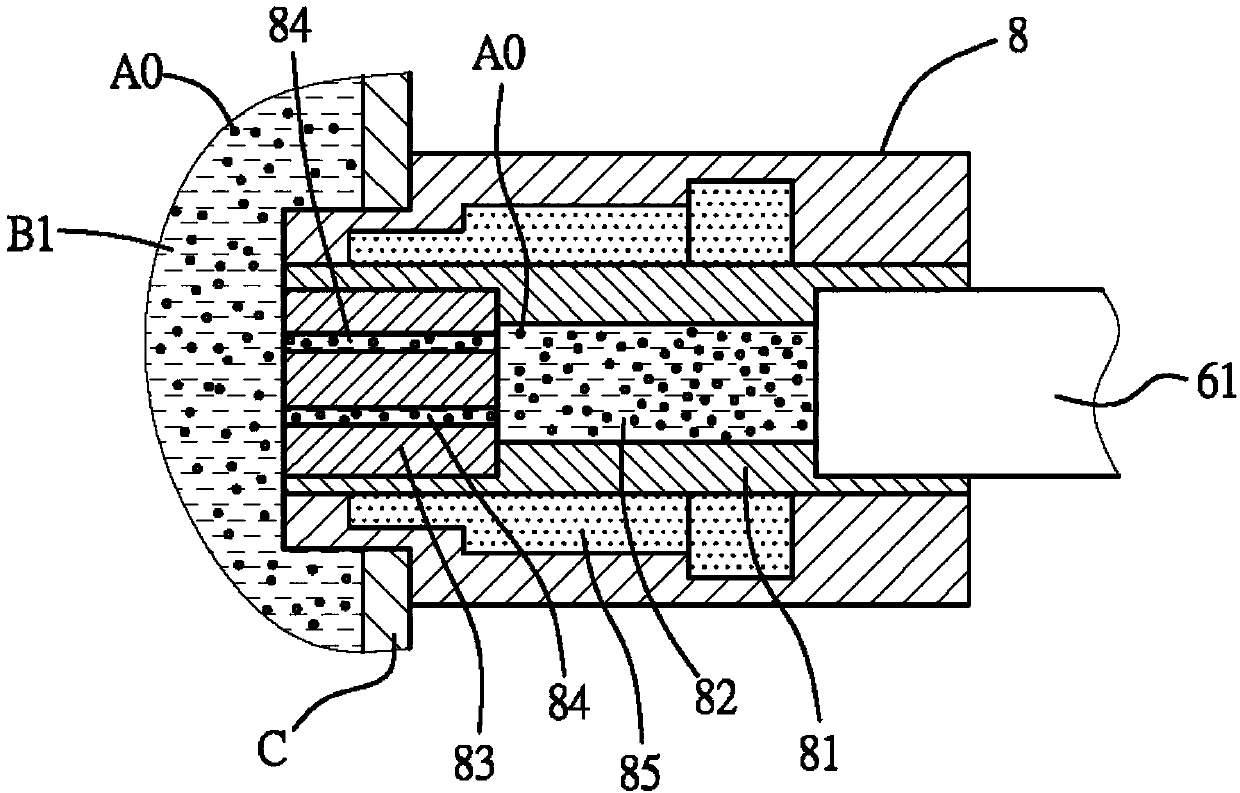

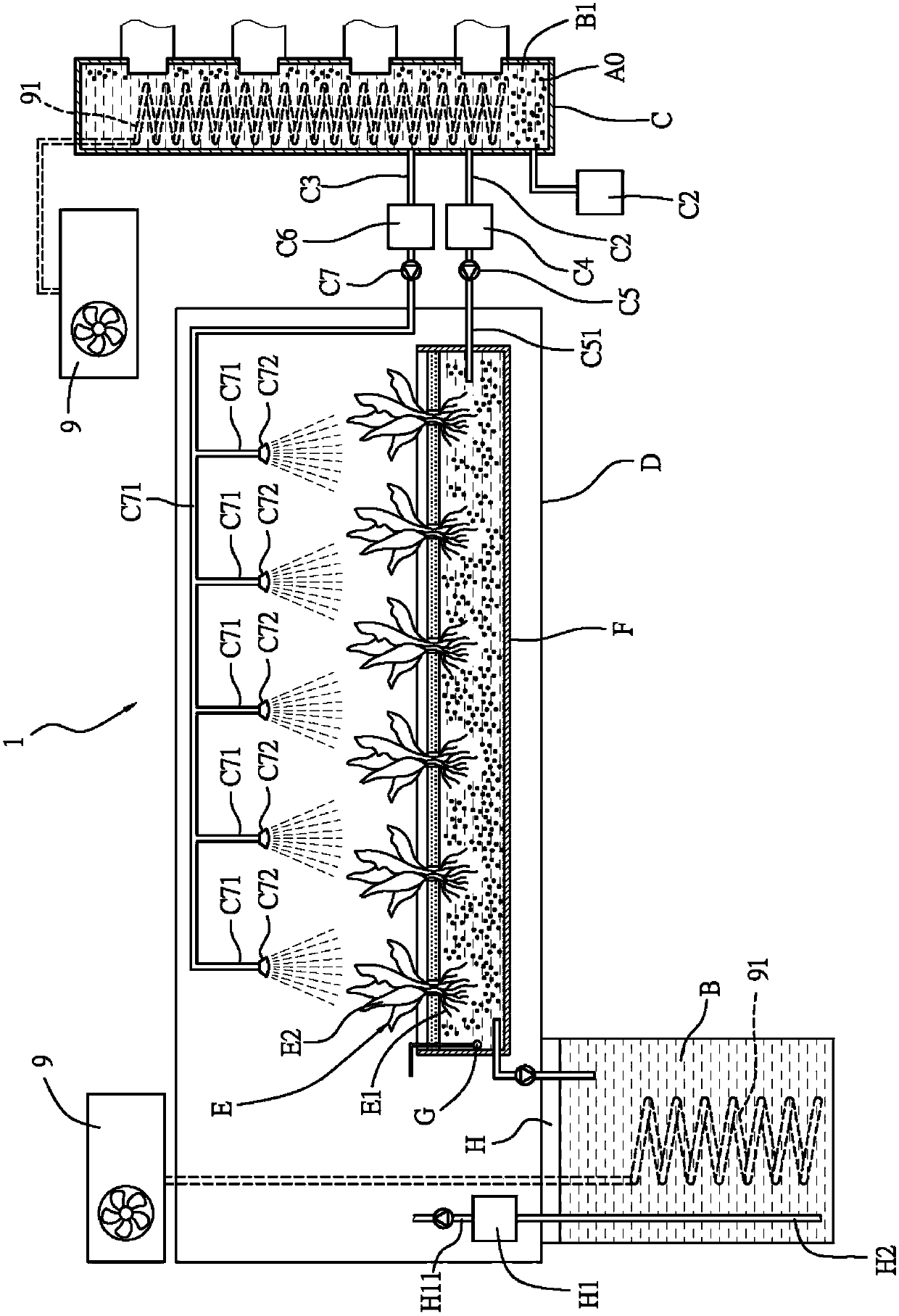

[0044] The present invention mainly provides a method for implementing multifunctional ultrafine bubble water. The implementation method is as follows: various exclusive air A stored separately is preset, and the types of the exclusive air A include at least: an ozone A1, an oxygen A2, A hydrogen A3 and a carbon dioxide A4; then, at least one of the exclusive air A can be selected to be injected into the water B and subjected to pressure to become microbubbles A0 with a diameter of less than 1 mm. At the same time, the microbubbles A0 are fused into the water B become a microbubble water B1, and then, the superfine bubble water B1 is temporarily stored in a pressure vessel C, and the superfine bubble water B1 is output from the pressure vessel C (such as: figure 1 shown).

[0045] That is, ozone A1, oxygen A2, hydrogen A3 and carbon dioxide A4 are provided for hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com