A countercurrent adsorption reaction device based on W catalyst + hydrogen peroxide homogeneous catalytic system and its application method

A technology of adsorption reaction and homogeneous catalysis, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low reaction efficiency, difficult separation and recovery of catalysts, insufficient contact between catalysts and reaction substrates, etc. Efficiency, achieve reuse, increase the effect of phase interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

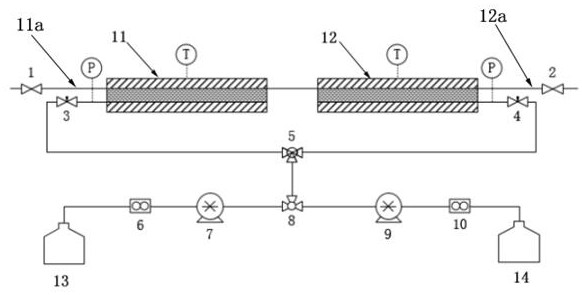

[0023] Example (comparison figure 1 ):

[0024] A countercurrent adsorption reaction device based on a W catalyst+hydrogen peroxide homogeneous catalytic system, including a reaction raw material feeding device, a hydrogen peroxide feeding device, a microscopic mixing device, a first fixed-bed reactor 11 and a second fixed-bed reactor 12, the The inside of the first fixed-bed reactor 11 is filled with W catalyst and the adsorbent for adsorbing W catalyst, and the inside of the second fixed-bed reactor 12 is filled with the adsorbent; the reaction raw material feeding device is fed with hydrogen peroxide The feeding device is connected with the liquid inlet of the micro-mixing device by a pipeline, and the liquid outlet of the micro-mixing device is divided into two paths, and one path is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com