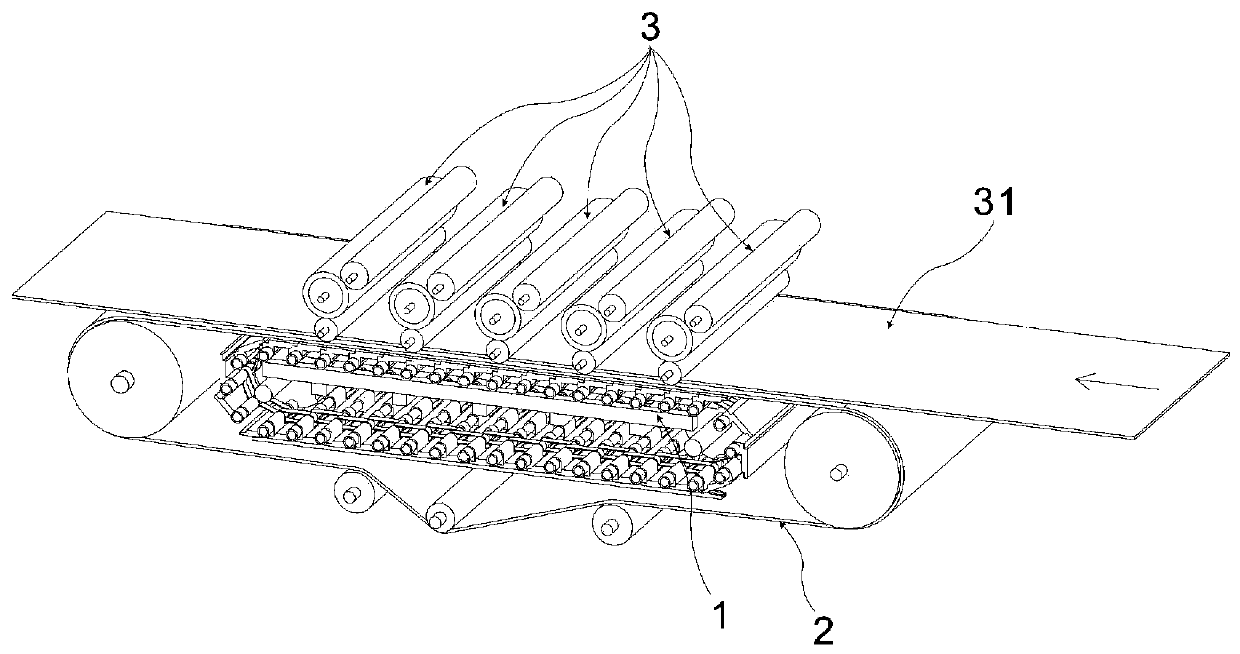

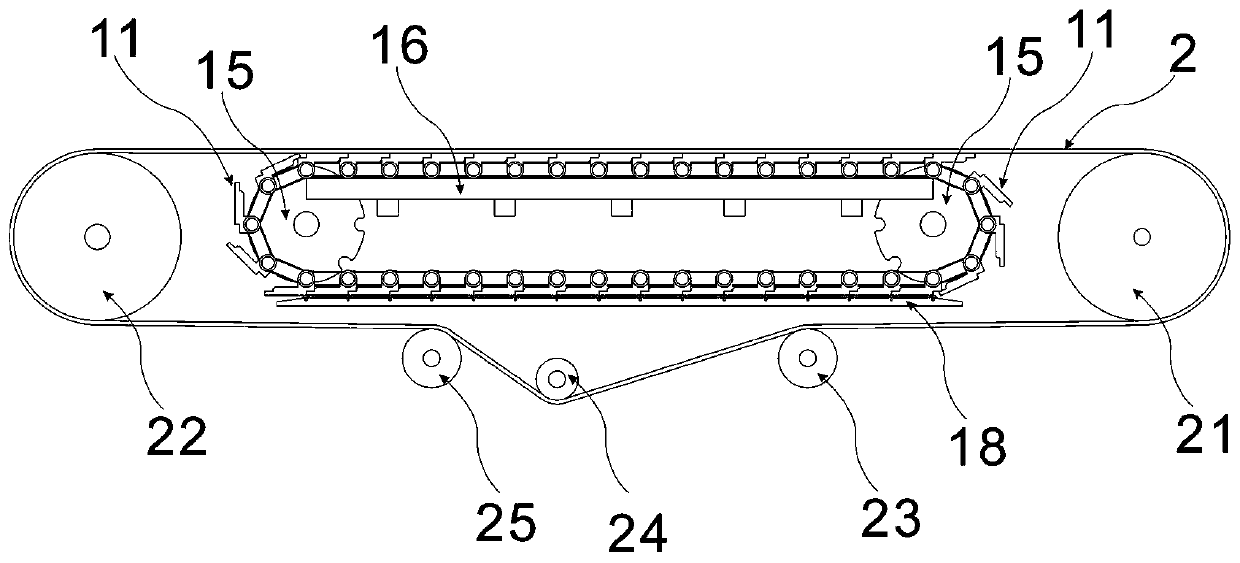

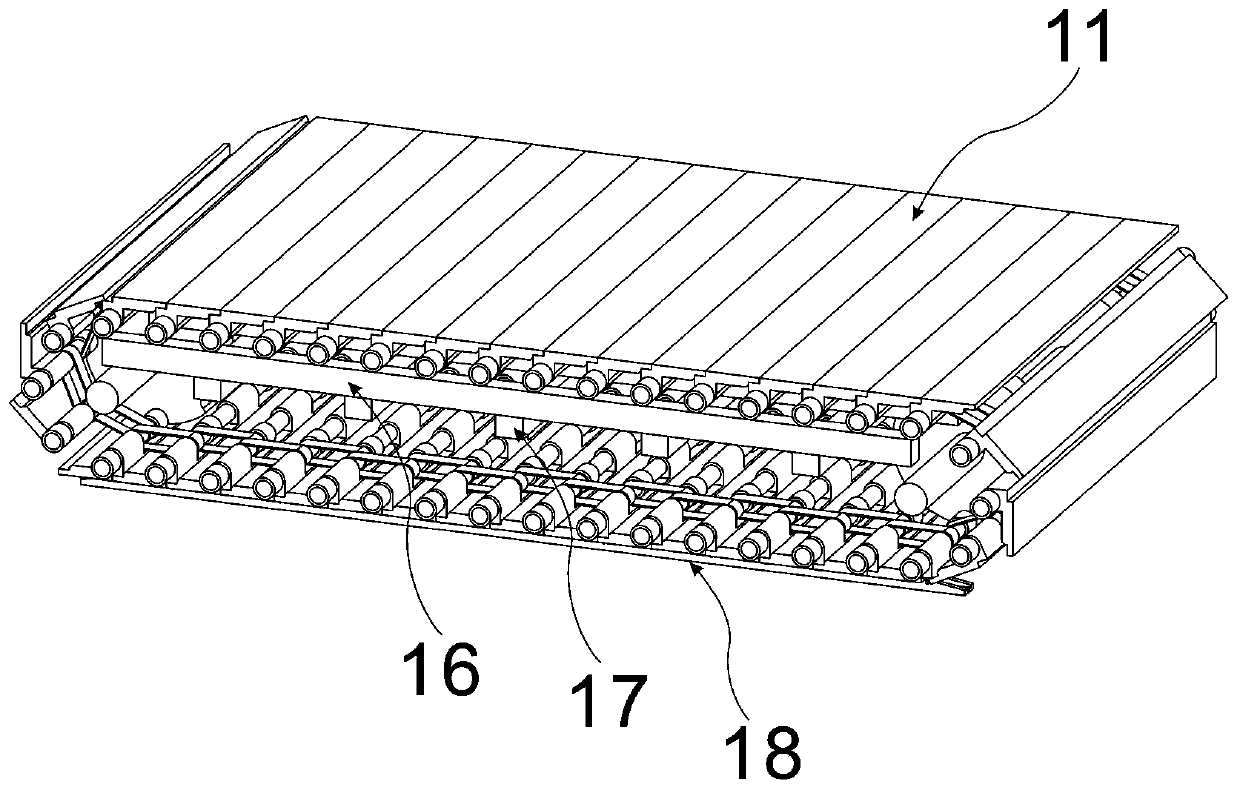

Chain plate guiding belt type version roller printing mechanism

A printing mechanism and chain plate technology, which is applied to printing machines, rotary printing machines, printing, etc., can solve problems such as distortion and easy deformation of the guide belt, and achieve the effects of improved accuracy, long printing time, and compact arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the traditional horizontal guide belt printing equipment, there is usually a roller shaft under the plate roller assembly for printing, and the roller shaft and the printing plate roller or transfer roller press the guide belt and the printing material between the two , especially in the wide-format printing process, in order to achieve a stable printing effect, a certain pressure is usually applied between the roller shaft and the printing plate roller or transfer roller through the cylinder. During the printing process, the guide belt needs to withstand the printing The moving horizontal pulling force also bears the vertical pulling force, especially between two adjacent plate printing components, it is easy to appear U-shaped depression or skewed deformation and distortion, which will seriously affect the quality of color printing. This situation is also very complicated and troublesome, the maintenance and debugging of the equipment are relatively difficult, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com