Automatic cleaning device for internal components of combing machine

A technology for automatic cleaning and internal parts, used in combers, fiber processing, textiles and papermaking, etc., can solve the problems of inability to meet the cleaning process, poor cleaning effect, etc., to avoid falling and drifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

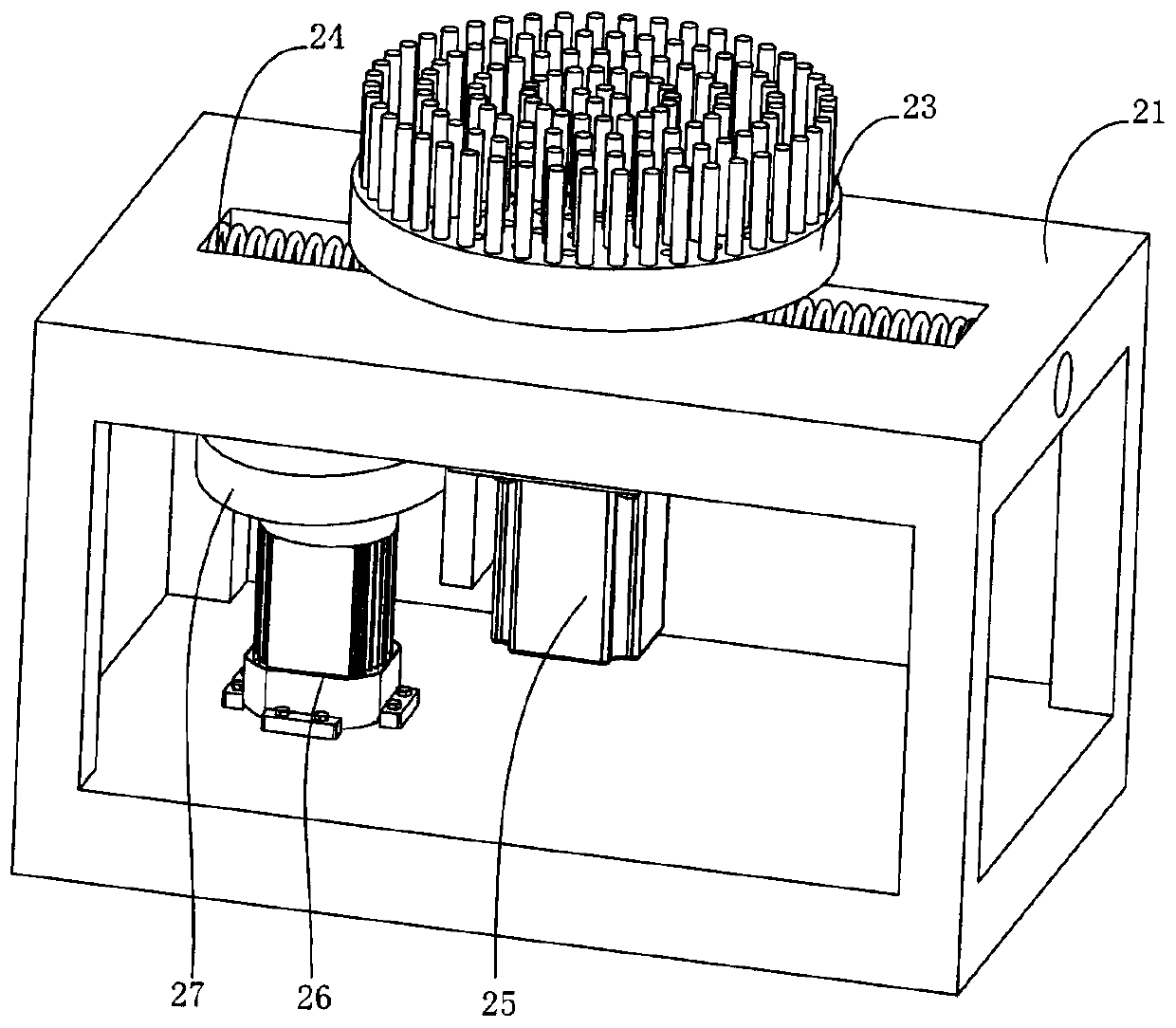

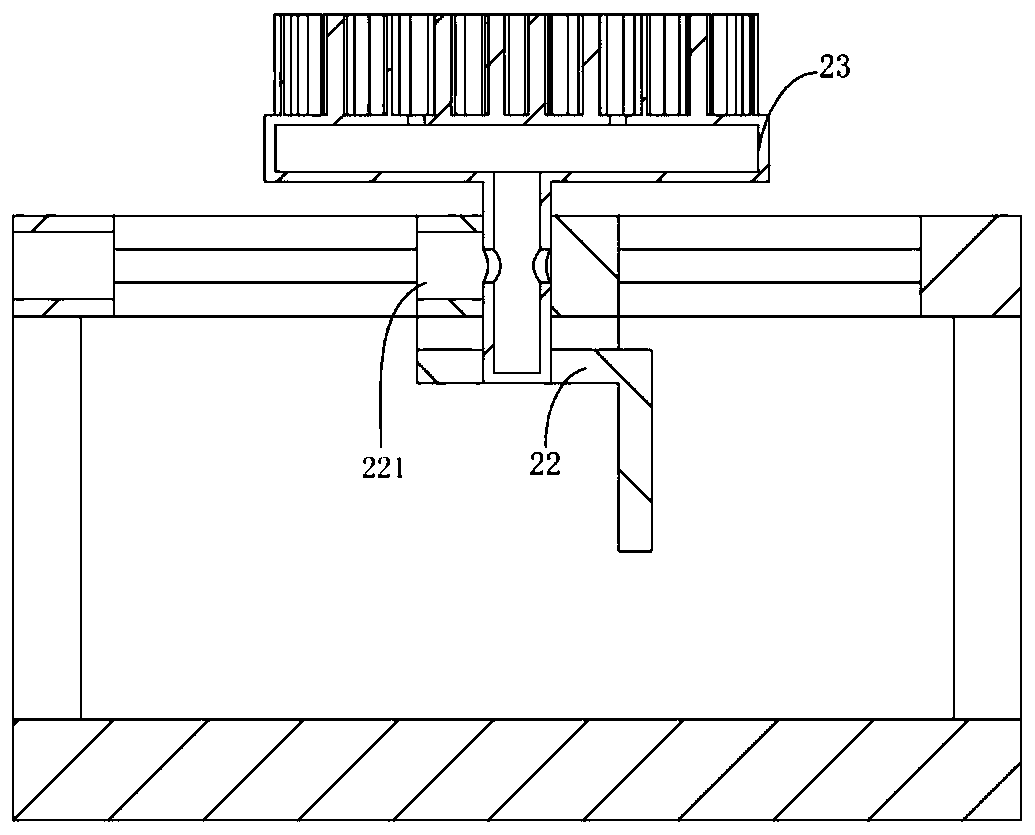

[0025] see Figure 2 to Figure 6 , the present invention provides a technical solution:

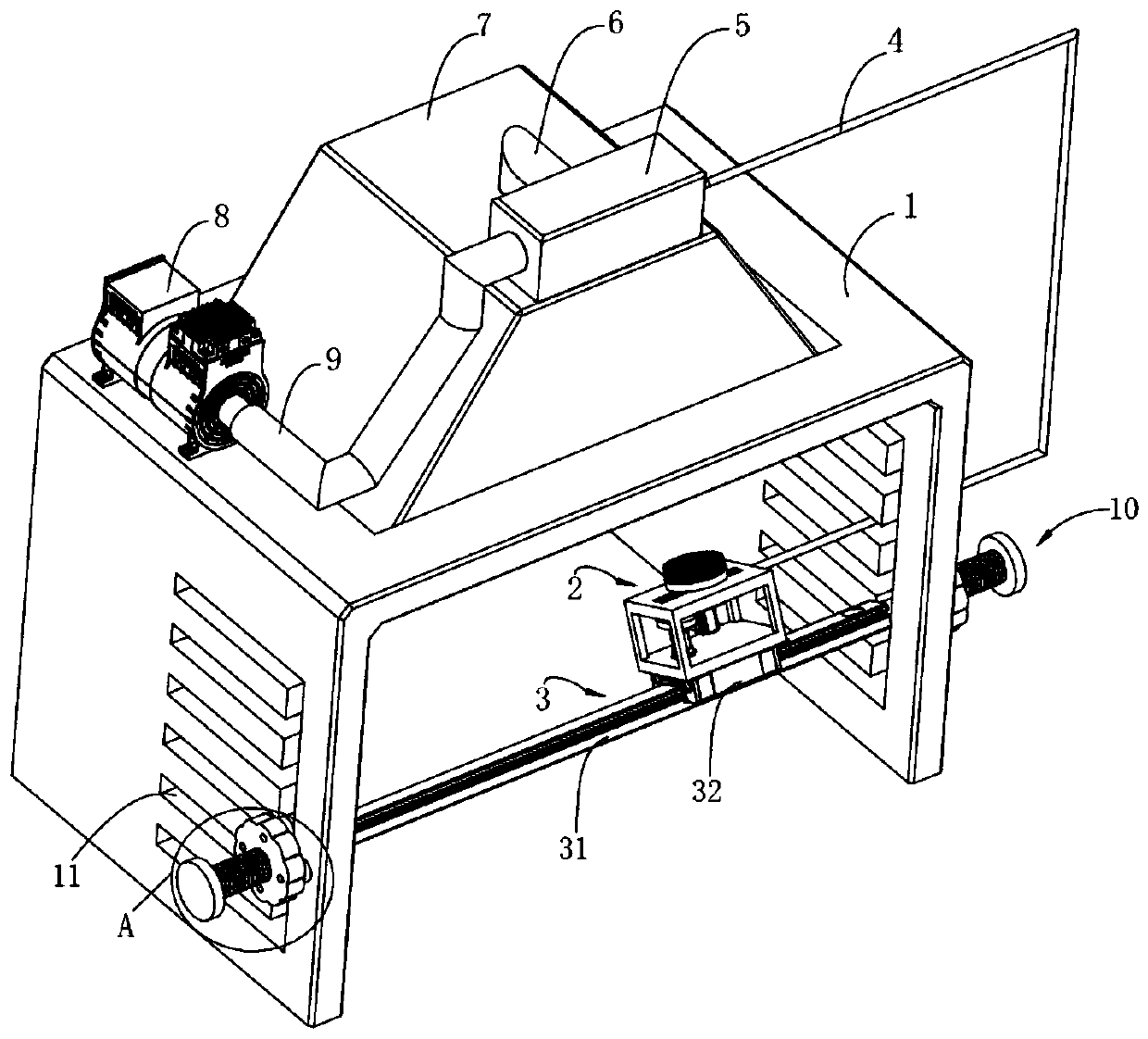

[0026] An automatic cleaning device for the internal parts of a combing machine, including a frame 1, a cleaning mechanism 2, a linear drive mechanism 3, a telescopic hose 4, a bag filter 5, an air outlet pipe 6, a dust cover 7, a fan 8, and an air inlet Trachea 9 and regulating mechanism 10, wherein:

[0027] The two sides of the frame 1 are provided with interconnected guide grooves 11, wherein the guide grooves 11 are set in both horizontal and vertical directions, the dust collection cover 7 is fixedly installed above the frame 1, and the bag dust collector 5 is installed on the dust collector. On the cover 7, it communicates with the dust collection cover 7 through the air outlet pipe 6, wherein the bag filter 5 is used for filtering impurities, and the fan 8 is fixed on the frame 1 through bolts, and it is connected to the bag filter 5 through the air inlet pipe 9. connected;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com