Pile lateral friction resistance test device and method for simulating indoor soil stress state around pile

A technology of stress state and test device, which is applied in the direction of basic structure test, construction, basic structure engineering, etc., can solve the problems of high estimation, consumption, and small guiding role of side friction resistance design, and achieve low cost and reliable design The effect of the parameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. It should be understood by those skilled in the art. The content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0034] In the description of the present invention, it should be understood that the terms "first", "second", and "third" are used for description purposes only, and the terms "first", "second" and "third" are limited to Characteristics do not imply any order, quantity or importance, but merely serve to distinguish different components.

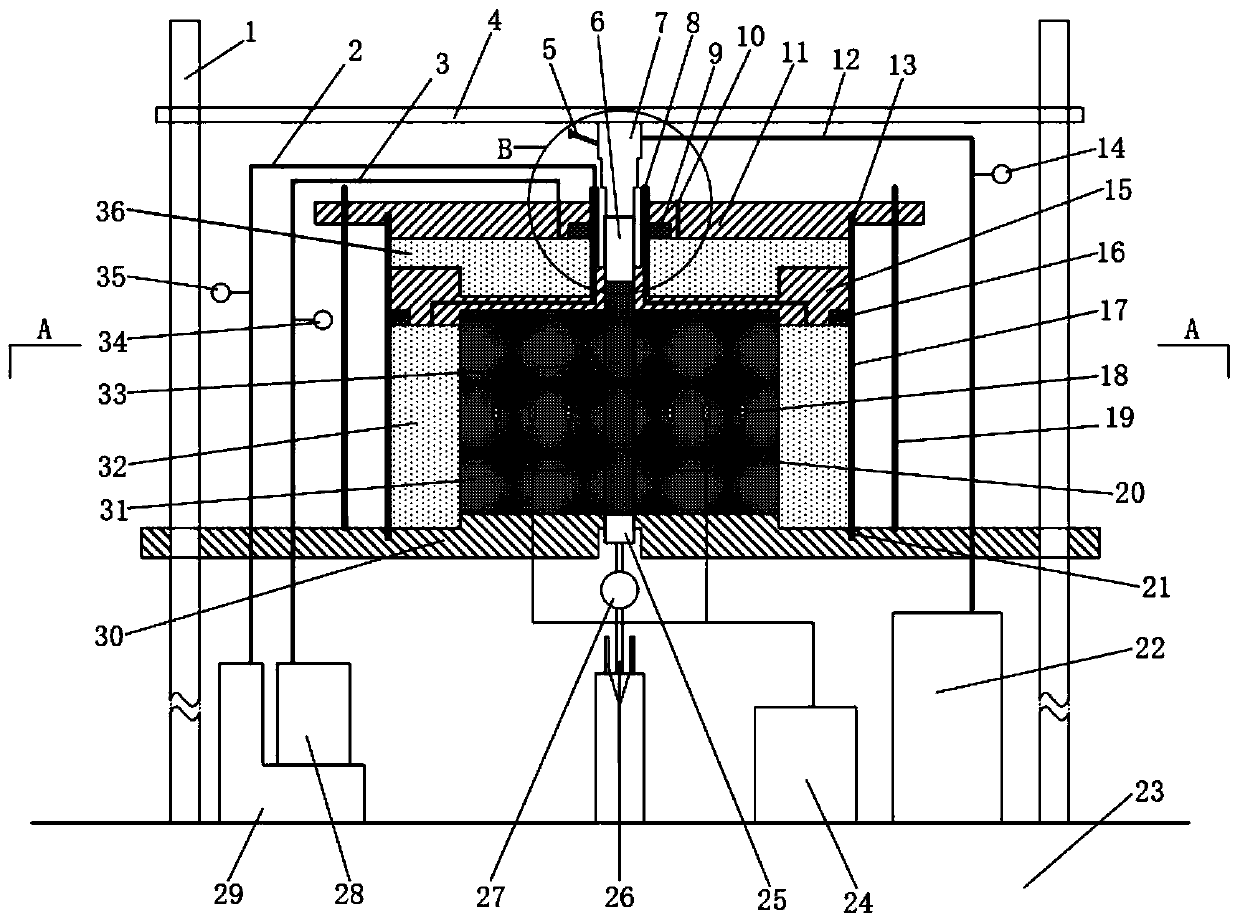

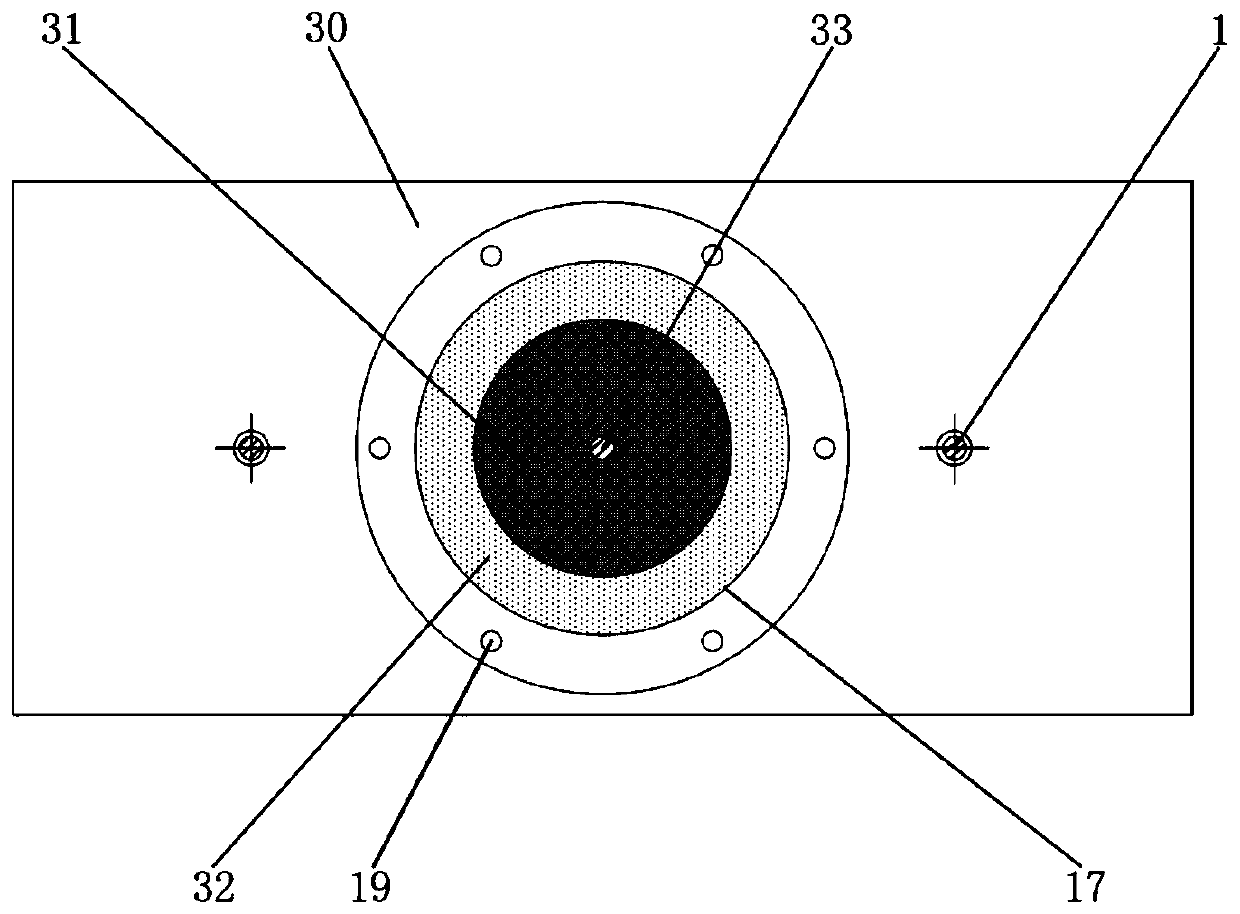

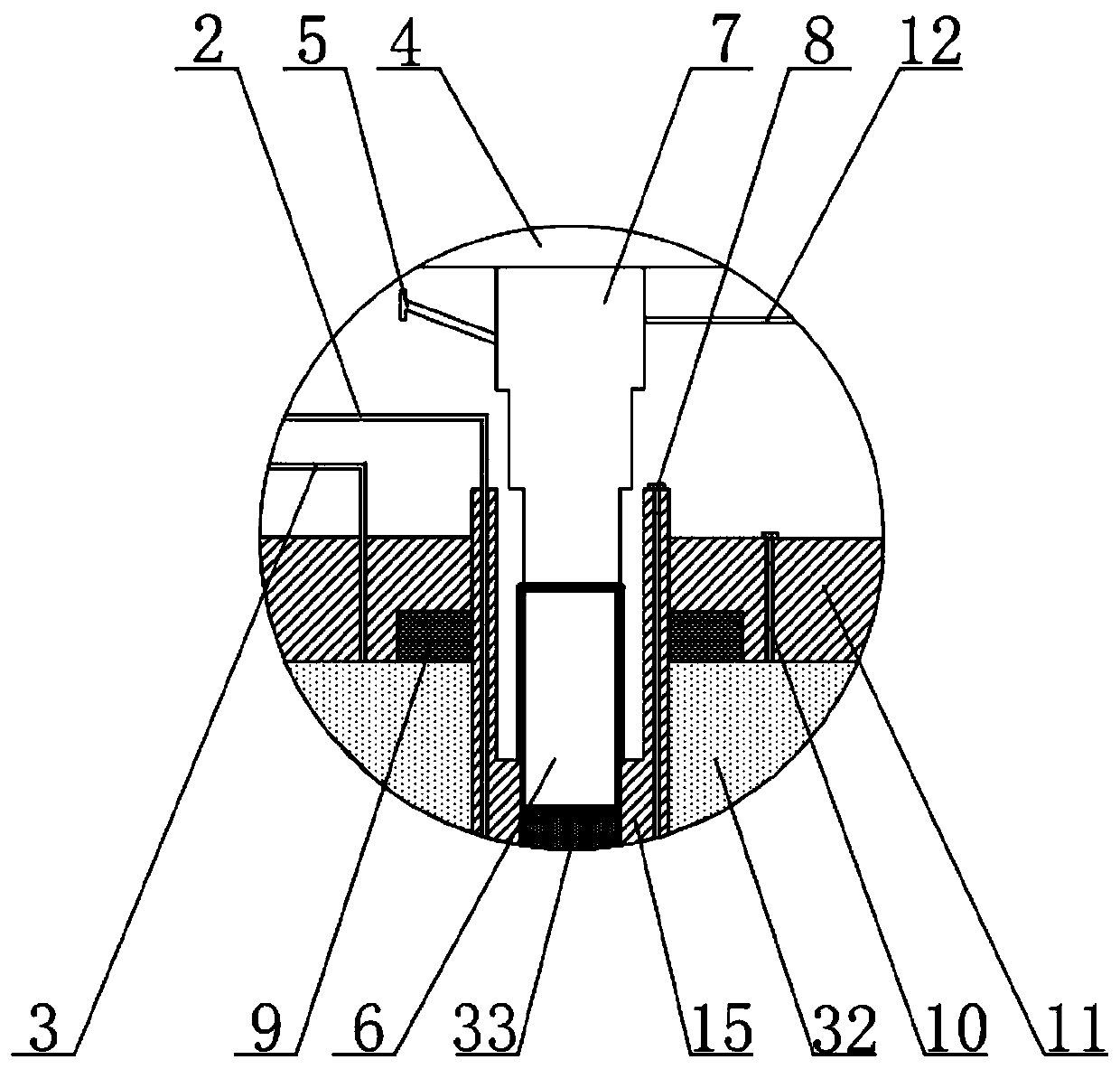

[0035] The purpose of the present invention is to restore the actual stress state of the soil around the pile in the stratum. Two sets of hydraulic devices apply the overlying soil pressure and the horizontal side pressure to the soil around the pile at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com