Calibration system of ship hydrophone

A hydrophone and ship technology, applied to vibration measurement in instruments and fluids, measuring vibration and other directions, can solve problems such as difficulty in ensuring the reliability and accuracy of data collected by hydrophones, and inability to measure and calibrate hydrophones.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

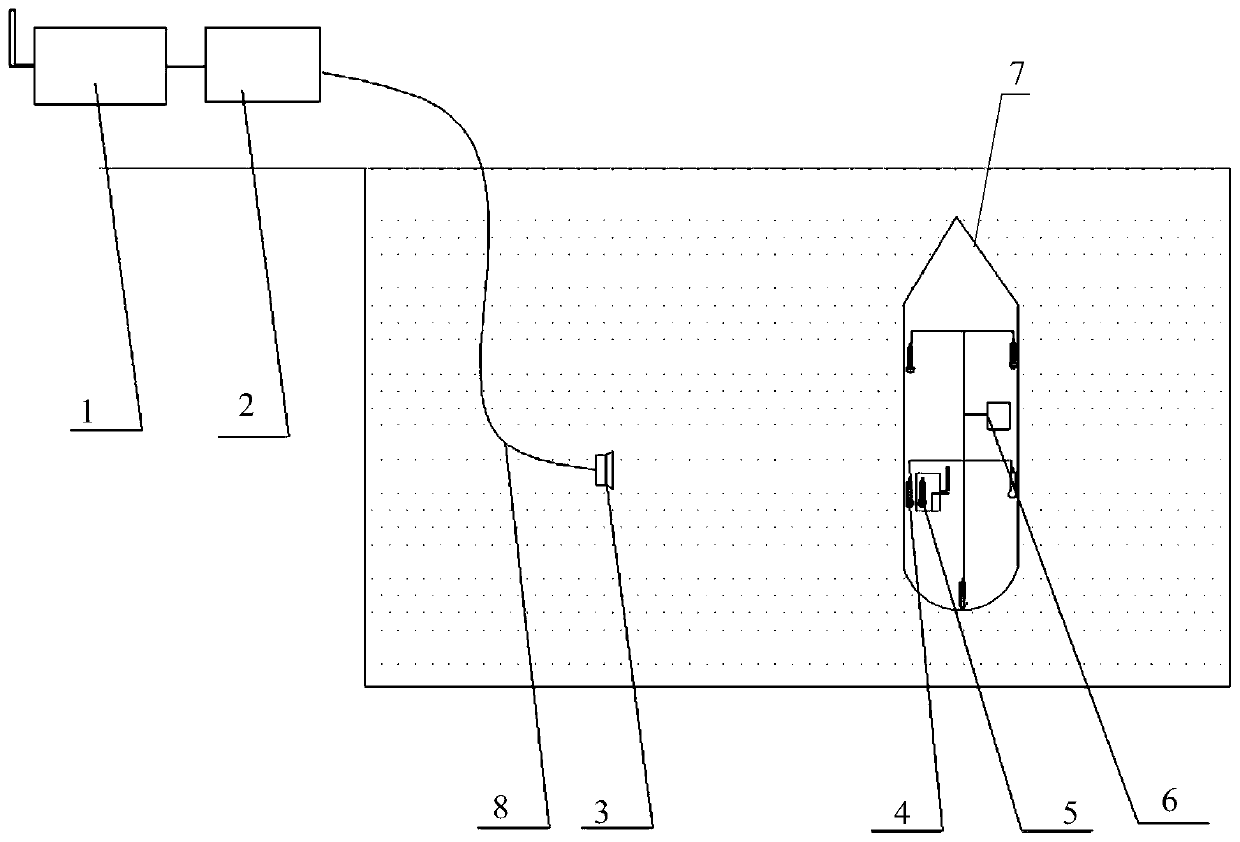

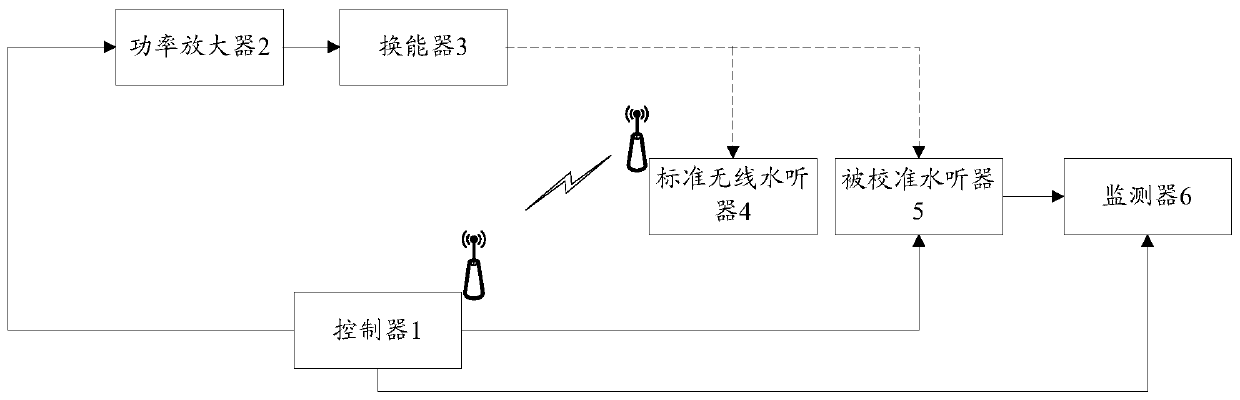

[0026] In order to solve the technical problem that the existing technology cannot conveniently and quickly measure and calibrate hydrophones that are fixedly installed on ships and are difficult to disassemble, which makes it difficult to ensure the reliability and accuracy of data collected by hydrophones, the present invention provides a A calibration system for a ship's hydrophone, the system comprising: a controller, connected to the input end of a power amplifier through a signal line, and used to send an excitation signal at a calibration frequency to the power amplifier; a power amplifier, the power amplifier The output terminal of the transducer is connected with the transducer for amplifying the excitation signal; the transducer, which is placed underwater, is used to convert the excitation signal into an acoustic signal; the calibrated hydrophone , installed on the ship structure, used to receive the acoustic signal, generate a first voltage response value according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Snr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com