Battery design method with multi-parameter synergistic effect

A technology of synergy and design method, applied in special data processing applications, computing, electrical digital data processing, etc., can solve problems such as changes in battery performance that are difficult to meet volume fraction changes

- Summary

- Abstract

- Description

- Claims

- Application Information

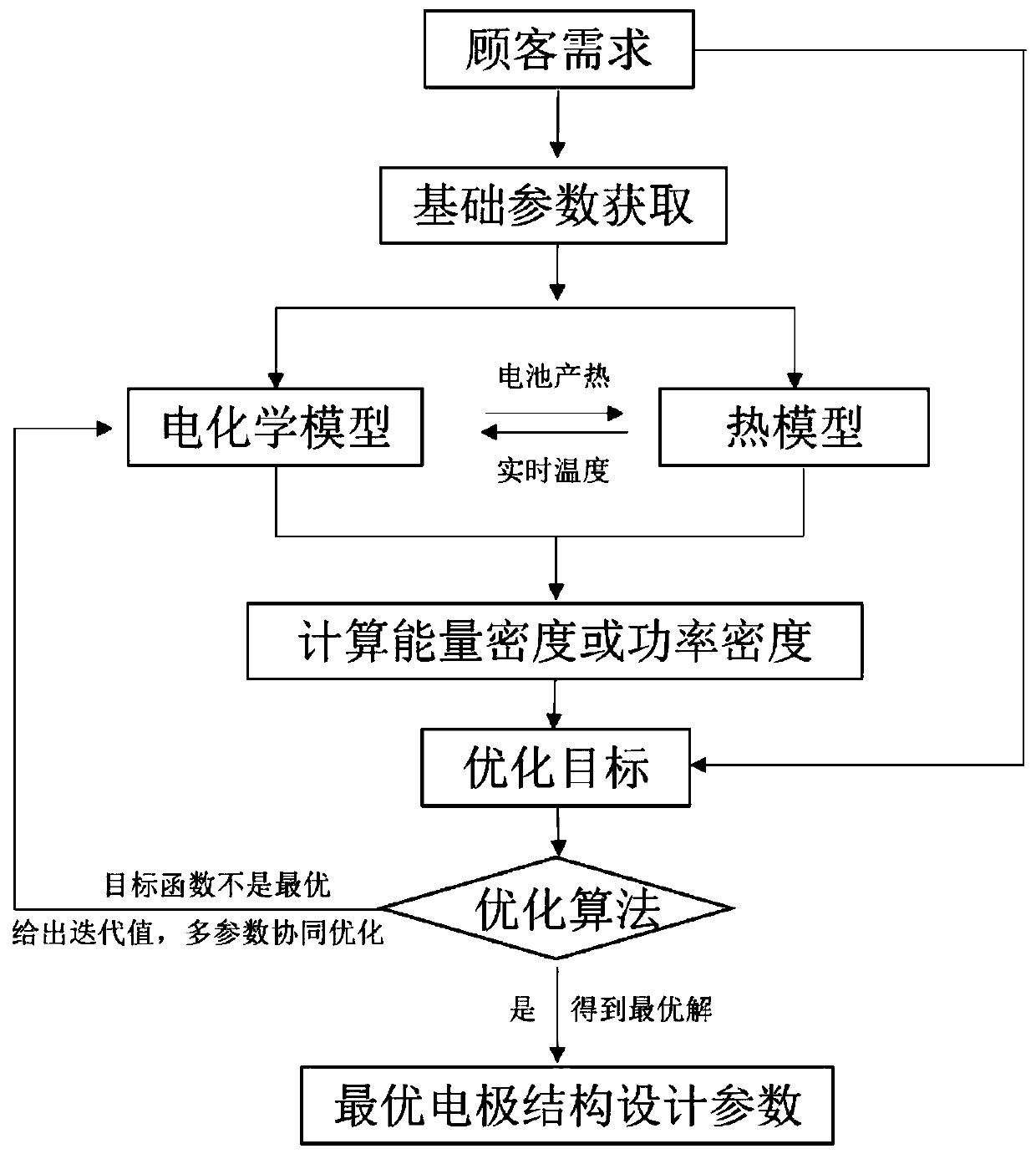

AI Technical Summary

Problems solved by technology

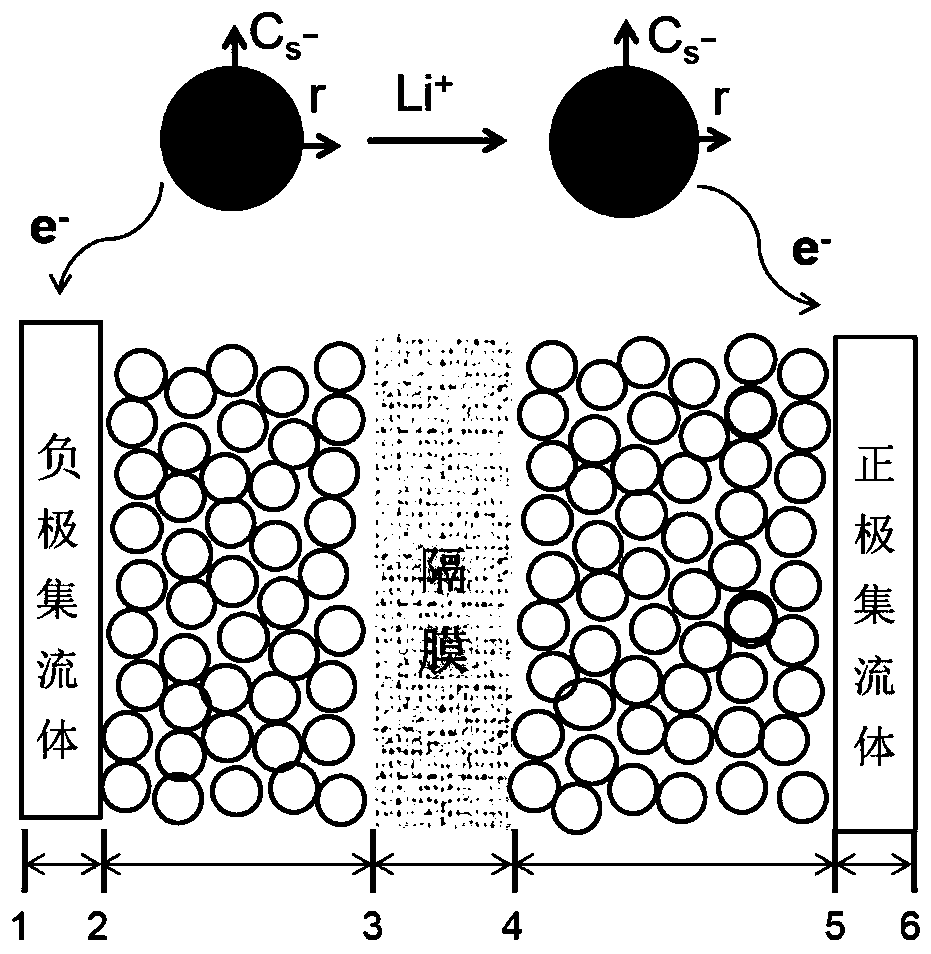

Method used

Image

Examples

Embodiment 1

[0034] Take the soft-pack lithium iron phosphate battery as an example. The customer’s battery size is shown in Table 1. The battery application is usually 1C discharge, which requires the battery to have the highest energy density, that is, under the 1C discharge condition, the energy density of the cell is maximized.

[0035] Table 1 Three-dimensional size parameters of the battery

[0036] width thickness high 100mm 12mm 115mm

[0037] According to the customer's needs, select the battery specifications similar to the requirements. The electrode design parameters of the battery selected in this embodiment, that is, the battery structure parameters. The battery structure parameters are shown in Table 2. Under this design, the energy density of the battery cell for 1C discharge is 159.40Wh / kg.

[0038] Table 2 Battery structure parameters

[0039]

[0040] Remarks: A slash means that the parameter does not exist or is not considered

[0041] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com