Semiconductor production line MES and experiment method thereof

An experimental method and production line technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve a large number of manual operations and other problems, and achieve the effect of improving overall production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

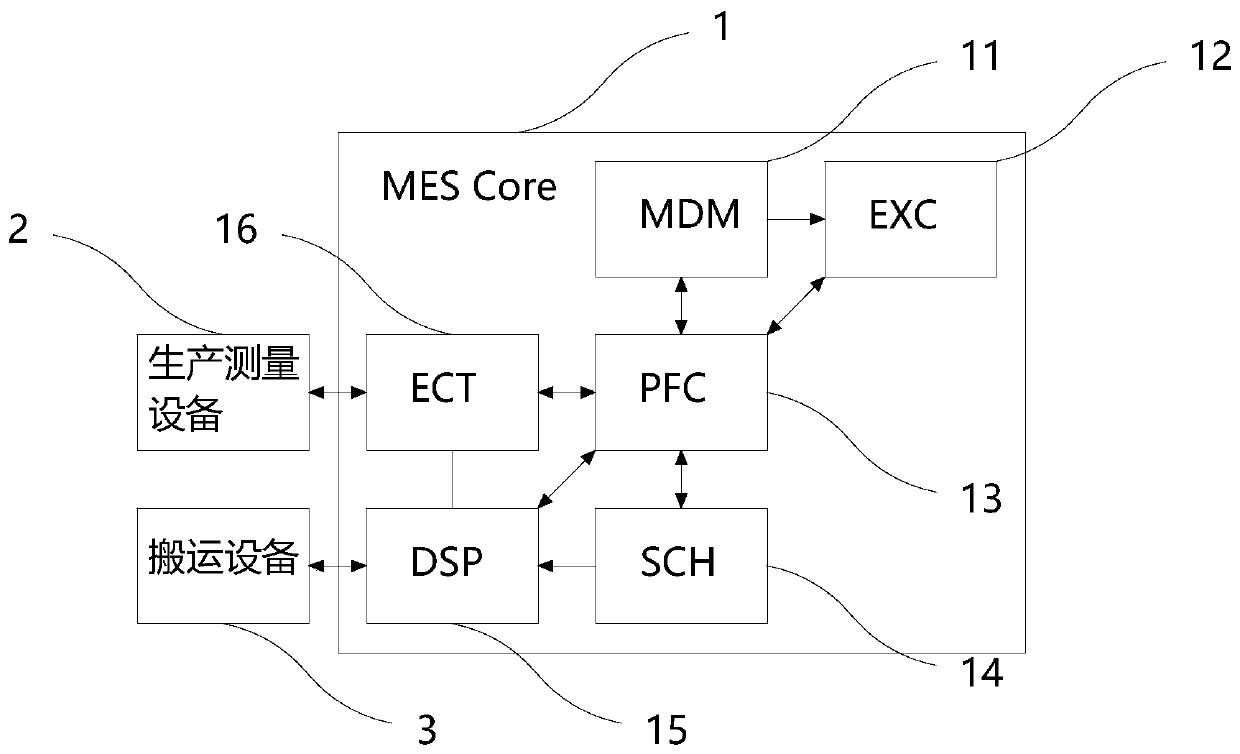

[0036] figure 1 It is a system block diagram of the semiconductor production line MES system of the present invention, please refer to figure 1 , a semiconductor production line MES system, including: MES core 1, MES core 1 includes: process flow control module 13 respectively communicates with equipment communication terminal 16, master data management module 11, scheduler 15, scheduler module 14, wherein, also An experiment management module 12 is included, and the experiment management module 12 communicates with the master data management module 11 and the technological process control module 13 .

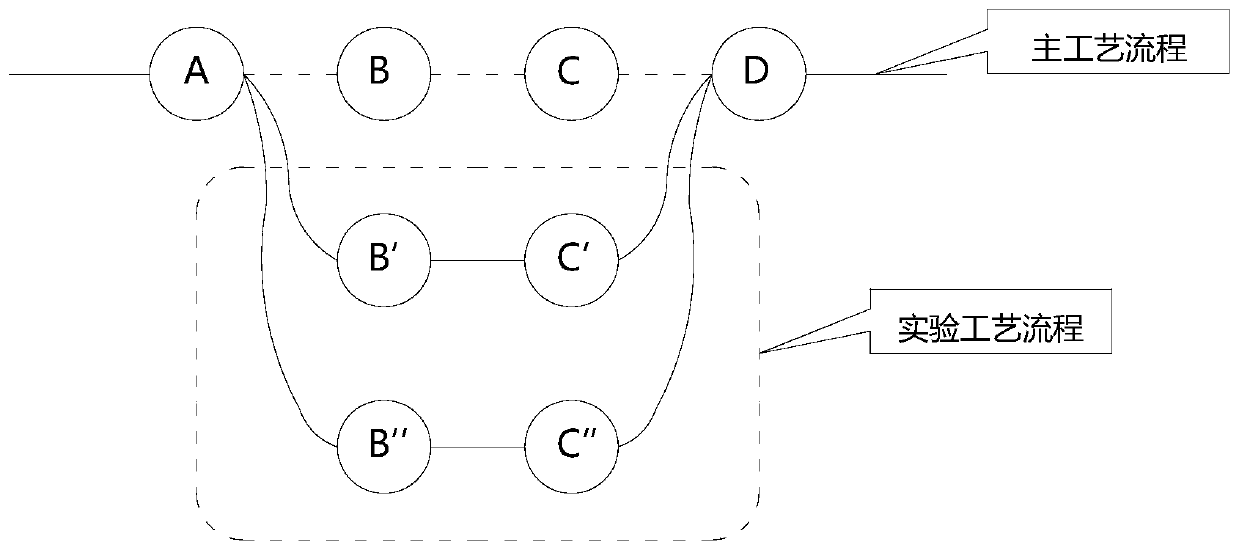

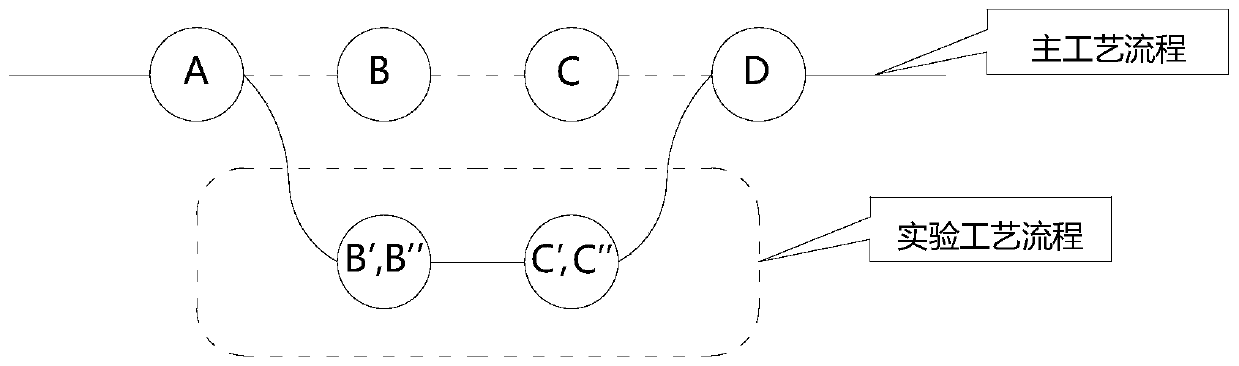

[0037] The present invention adds a functional module of experiment management to the MES system, which is relatively independent from other modules in the MES system, and is managed through the setting of the experiment process. The experimental process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com