LED constant-current driving device and driving method

A technology of constant current drive and drive method, which is applied in the direction of lighting devices, light sources, electrical components, etc., can solve the problems of poor performance and high failure rate of constant current drive circuits, and achieve no color shift, long life, and good energy-saving effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

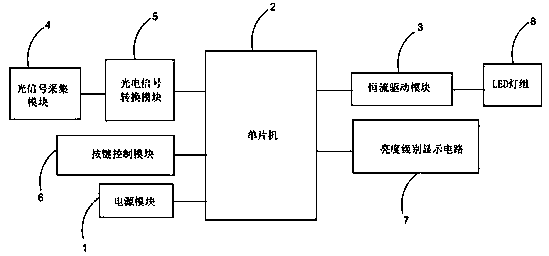

[0046] Such as figure 1 As shown, an LED constant current driving device is used to control the display of LED lamp group 8 (consisting of multiple LED lamps connected in series / parallel / series-parallel), including:

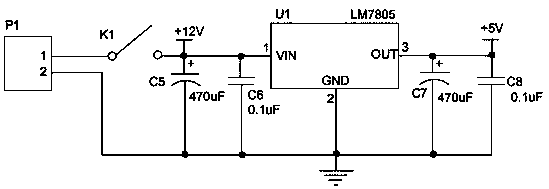

[0047] A power module 1, used to supply power to the device;

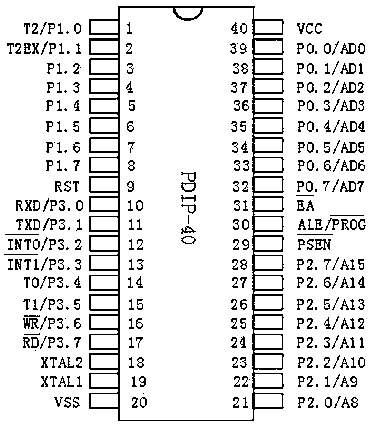

[0048] The single-chip microcomputer 2 is electrically connected with the power supply module 1, in order to realize the overall control of the device;

[0049] The constant current drive module 3 is electrically connected with the mains voltage, the single-chip microcomputer 2 and the LED lamp group 8, in order to provide a constant current for the LED lamp group 8;

[0050] The optical signal acquisition module 4 is used to regularly acquire optical signals;

[0051] The photoelectric signal conversion module 5 is electrically connected with the optical signal acquisition module 4 and the single-chip microcomputer 2, and is used to receive the optical signal and control the current output by the c...

Embodiment 2

[0078] According to the LED constant current driving device provided in the above embodiments, this embodiment provides a driving method for the LED constant current driving device.

[0079] A driving method for an LED constant current driving device, comprising the steps of:

[0080] S1, the single-chip microcomputer 2 scans the button to judge whether the manual signal sent by the button control module 6 is received, if so, execute step S2; otherwise, execute step S5;

[0081] S2. Determine the signal type of the manual signal. If the signal is increased, step S3 is performed; if the signal is decreased, step S4 is performed;

[0082] S3, the single-chip microcomputer 2 sends an increase signal to the constant current drive module 3, the output current of the constant current drive module 3 increases, and the brightness of the LED lamp group 8 increases;

[0083] S4, the single-chip microcomputer 2 sends a reduction signal to the constant current drive module 3, the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com