Device and method for removing air bubbles in shear-thinning non-Newtonian fluid

A non-Newtonian fluid and bubble technology, applied in separation methods, liquid degassing, chemical instruments and methods, etc., can solve the problems of low removal efficiency of new bubbles and bubbles, complex composition of vacuum degassing devices, large baffle area, etc. Achieving the effects of wide application range, accelerated rising speed and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

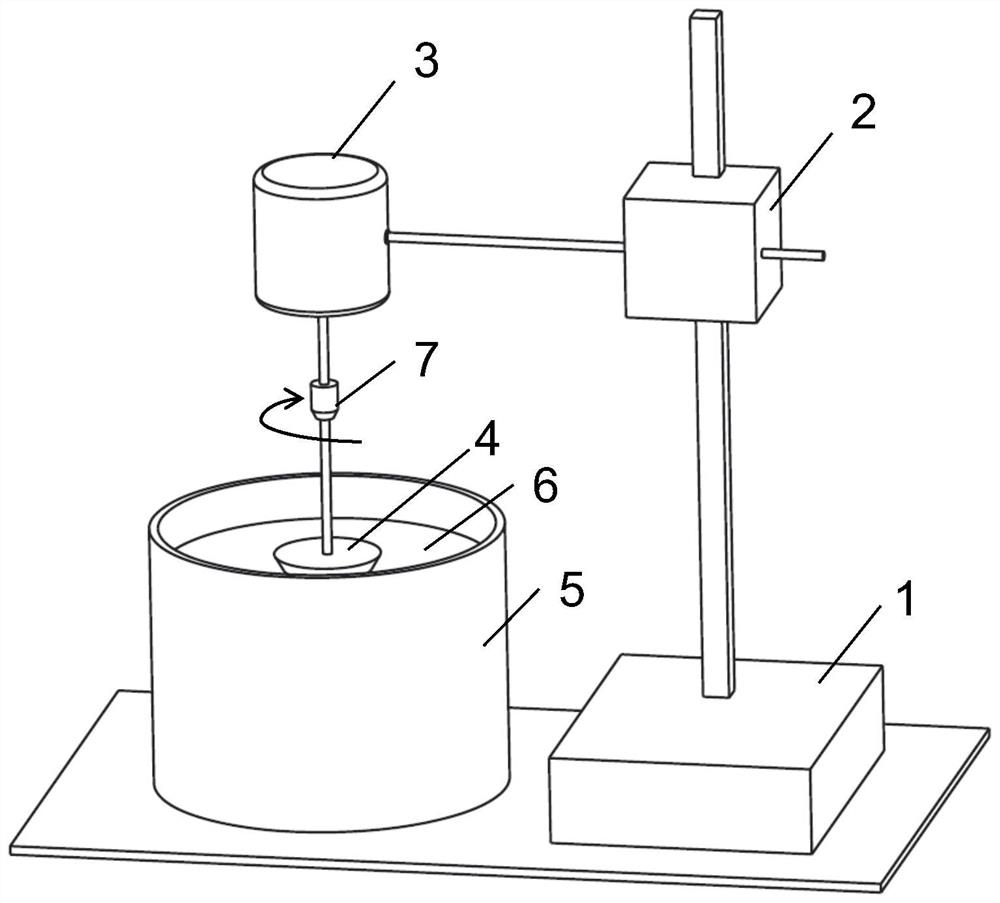

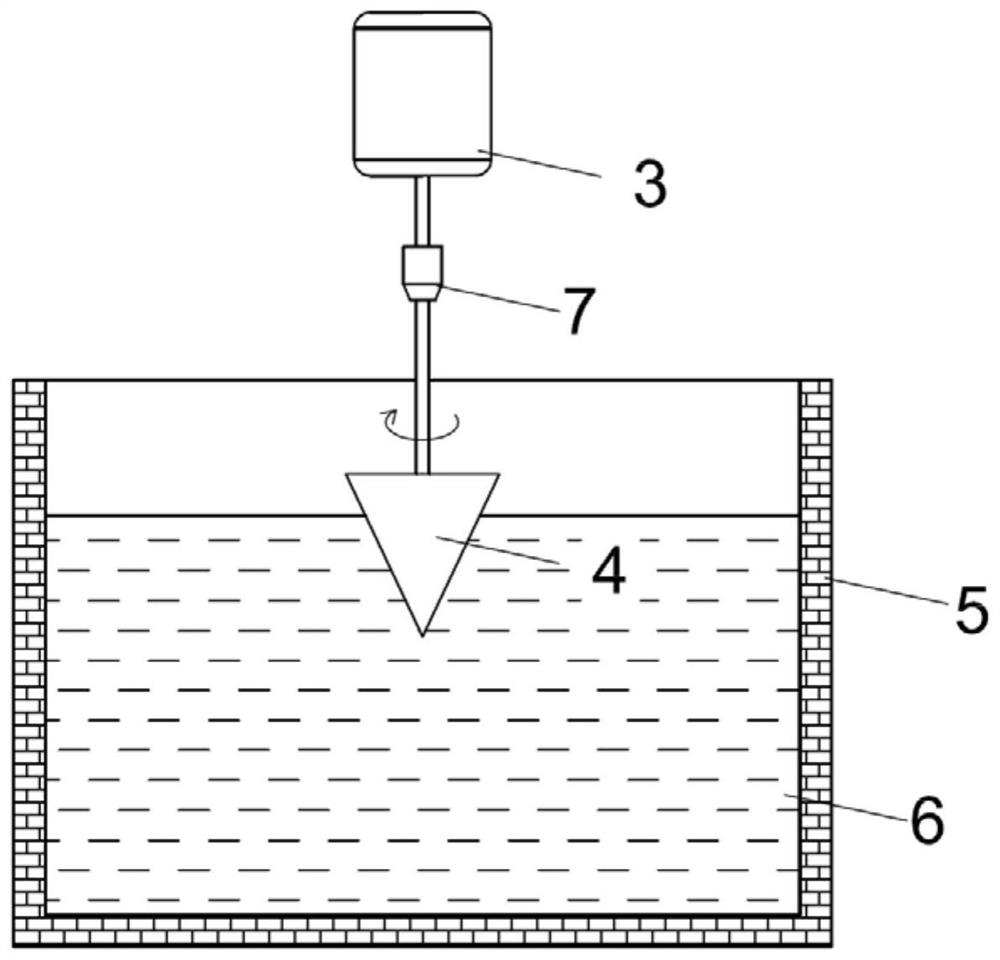

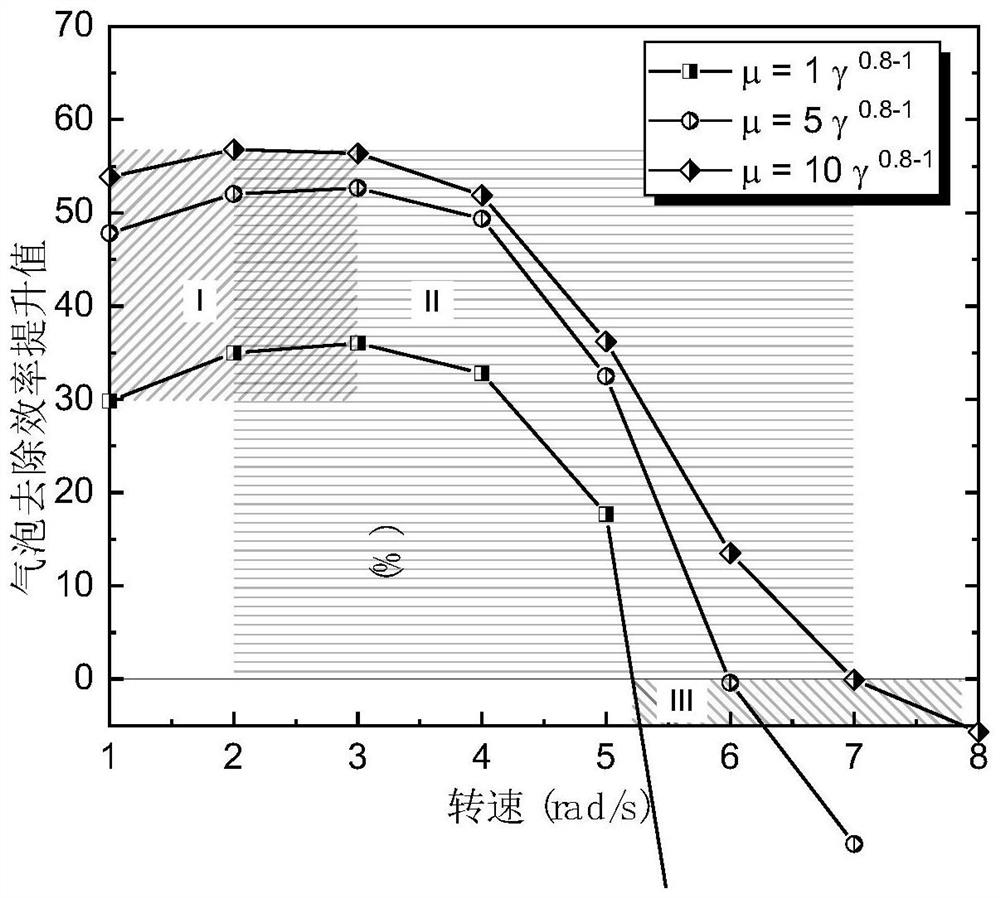

[0045] The inner diameter of the liquid container is 200mm, the height of the shear thinning non-Newtonian fluid is 200mm, the diameter of the conical stirring head at the liquid surface is 60mm, the length of the conical stirring head extending into the liquid is 100mm, and the rotating mechanism controls the stirring The rotational speed of the rod is 3rad / s, and the parameters of the shear thinning non-Newtonian fluid are k=1, n=0.8. The gas removal process obtained by numerical simulation is as follows image 3 and Figure 4 As shown, compared with the state without stirring, the removal efficiency of air bubbles under stirring increased by 36.03%.

Embodiment 2

[0047] The inner diameter of the liquid container is 200mm, the height of the shear thinning non-Newtonian fluid is 200mm, the diameter of the conical stirring head at the liquid surface is 60mm, the length of the conical stirring head extending into the liquid is 100mm, and the rotating mechanism controls the stirring The rotational speed of the rod is 3rad / s, and the parameters of the shear thinning non-Newtonian fluid are k=1, n=0.8. According to the numerical simulation results, compared with the static state, the removal efficiency of air bubbles under stirring is increased by 68.35%.

Embodiment 3

[0049] The inner diameter of the liquid container is 200mm, the height of the shear thinning non-Newtonian fluid is 200mm, the diameter of the conical stirring head at the liquid surface is 60mm, the length of the conical stirring head extending into the liquid is 100mm, and the rotating mechanism controls the stirring The rotational speed of the rod is 3rad / s, and the parameters of the shear thinning non-Newtonian fluid are k=1, n=0.6. According to the numerical simulation results, compared with the static state, the removal efficiency of air bubbles under stirring is increased by 52.66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com