Chinese cymbal production equipment

A production equipment and base plate technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems affecting the health of workers, the inability to clamp and fix the anti-cymbal, and the inconvenience of production and grinding, so as to protect the health of the body , fast and convenient clamping and fixing, avoiding the effect of inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

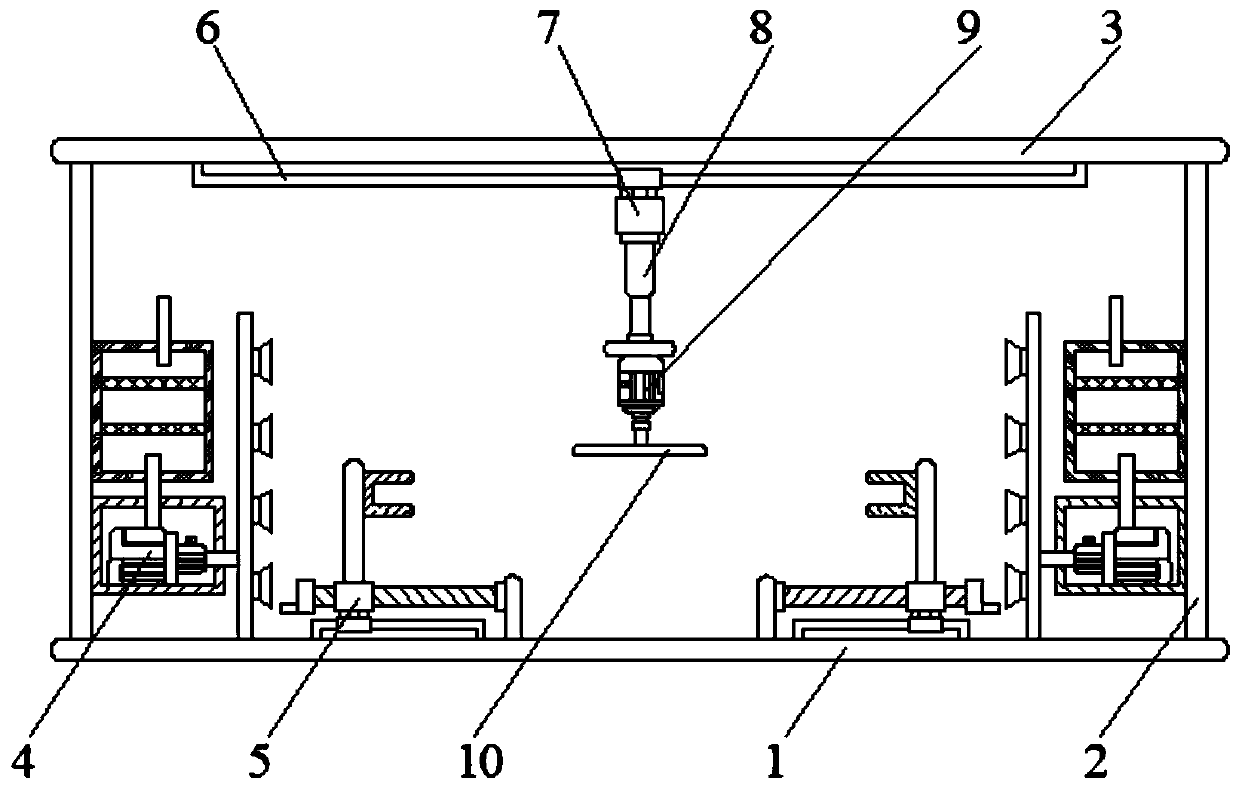

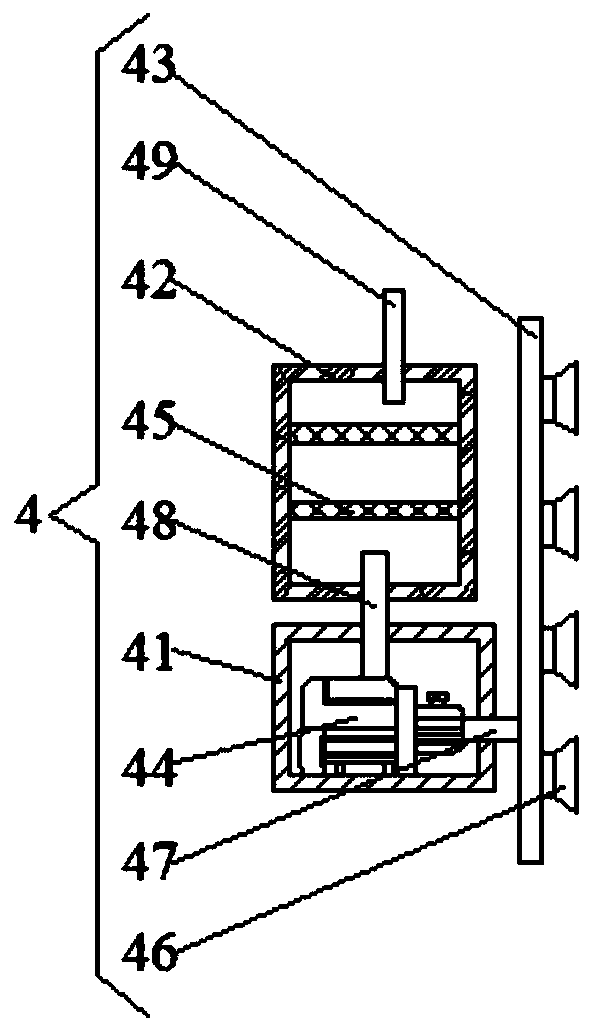

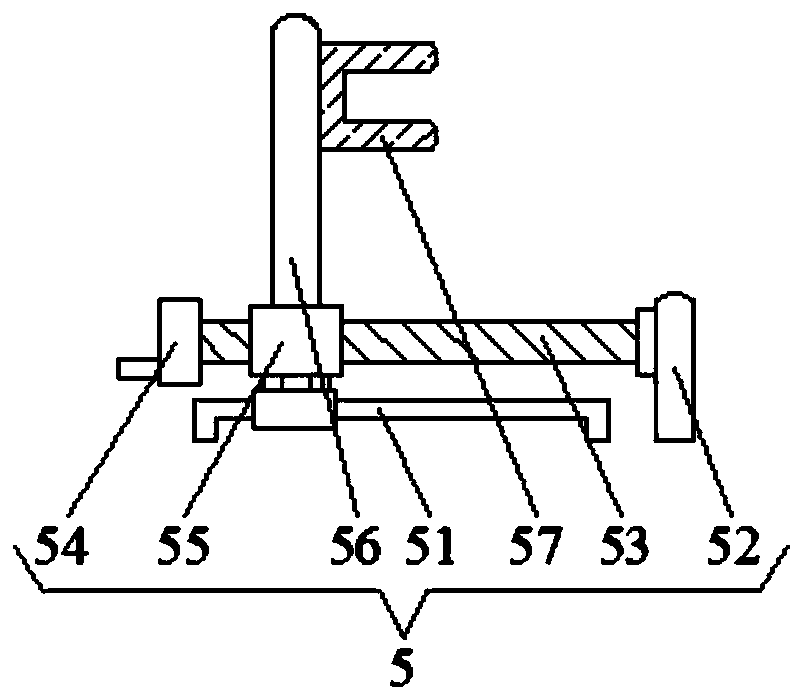

[0021] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

[0022] see Figure 1-3 According to an embodiment of the present invention, a kind of anti-cymbal production equipment includes a bottom plate 1, vertical plates 2 are fixedly connected to both sides of the top of the bottom plate 1, and horizontal plates 3 are fixedly connected to the tops of the two vertical plates 2. A dust removal device 4 is fixedly connected between one side of each vertical plate 2 and the top of the bottom plate 1, and the dust removal device 4 includes a fixed box 41, a stable box 42 and a shunt pipe 43, and the bottom of the inner wall of the fixed box 41 An aspirator 44 is fixedly connected, two filter screens 45 are fixedly connected between the two sides of the inner wall of the stability box 42, and a suction nozzle 46 is communicated with one side of the outer surface of the shunt pipe 43, and the aspirator 44 The air inlet is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com