A centrifugal spinning device

A spinning device and spinning device technology, applied in the field of centrifugal spinning spinning device, can solve problems such as easy leakage, rising pipeline pressure, unrealized technology, etc., and achieve the effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

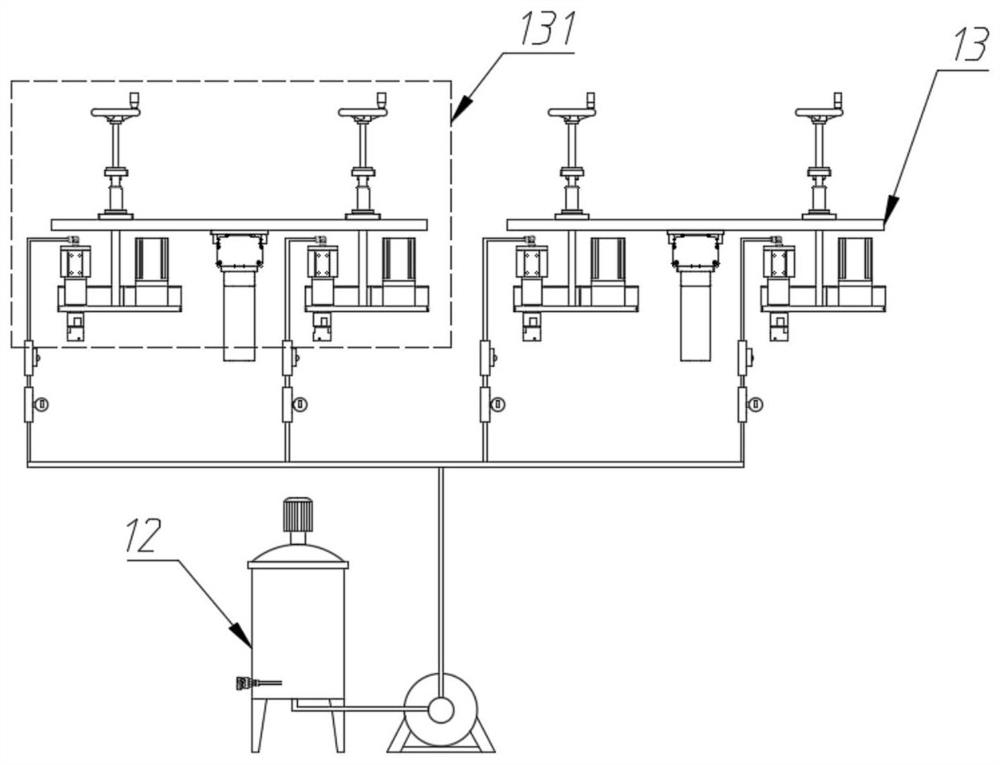

[0046] Such as figure 1 Shown, a kind of centrifugal spinning spinning device comprises feeding device 12 and spinning device 13; Described feeding device 12 feeds material to described spinning device 13; Described spinning device 13 carries out centrifugal spinning; The spinning device 13 includes at least one set of spinning units 131, and the number of spinning units 131 is selected according to the thickness requirement of the centrifugally spun fiber web.

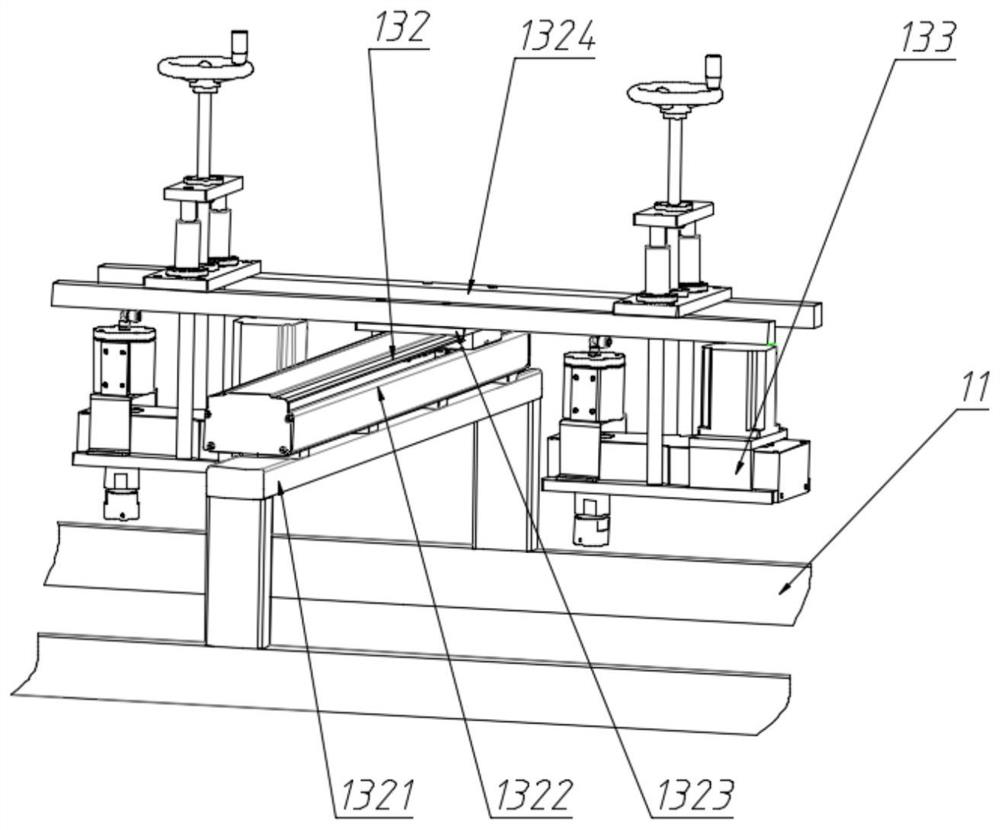

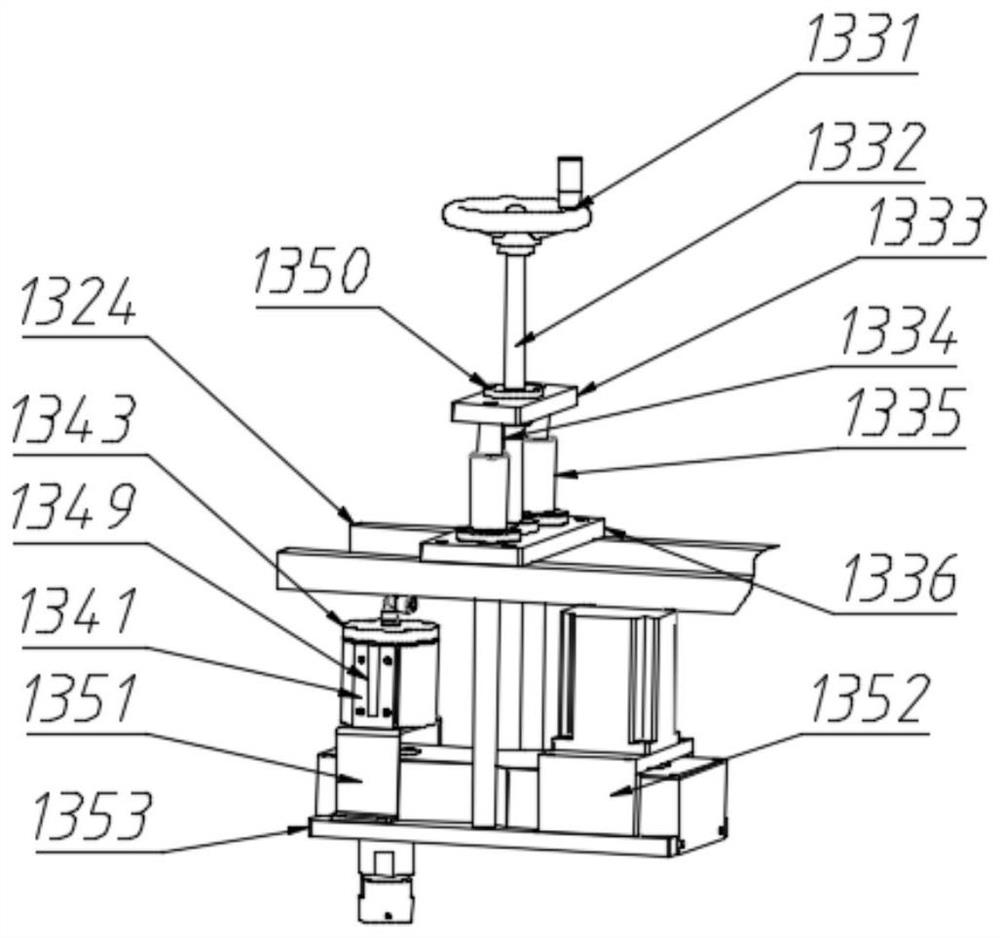

[0047] Such as figure 2 As shown, the spinning unit 131 includes a traversing device 132 and two sets of spinning devices 133 symmetrically installed on both sides of the traversing device 132; the traversing device 132 is fixedly installed on the frame 11; The moving device 132 drives the spinning device 133 to perform a horizontal reciprocating movement above the collecting device 14, so that the spinning fibers ejected from the spinning device 133 cover the entire collecting device 14.

[0048] The traversing de...

Embodiment 2

[0066] The difference with embodiment 1 is that, in the spinner device 133 in embodiment 2, at least one spinneret 1354 is installed on its said spinneret 1340; The shape of shown spinneret is as follows Figure 7 As shown, its inner diameter gradually becomes smaller to form a cone; the spinning solution in the spinneret 1340 is ejected through the spinneret 1354 .

Embodiment 3

[0068] The difference with embodiment 1 is that, in the spinner device 133 in embodiment 3, at least one spinneret 1354 is installed on its said spinneret 1340; The shape of shown spinneret is as follows Figure 8 As shown, its structure is in the form of steps; the spinning solution in the spinneret 1340 is ejected through the spinneret 1354 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com