Steam brush head and garment steamer

A steam brush and steam technology, applied in laundry room devices, washing devices, wrinkle-removing and flattening equipment, etc., can solve problems such as poor ironing effect of a garment ironing machine, achieve good ironing effect, and ensure close contact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

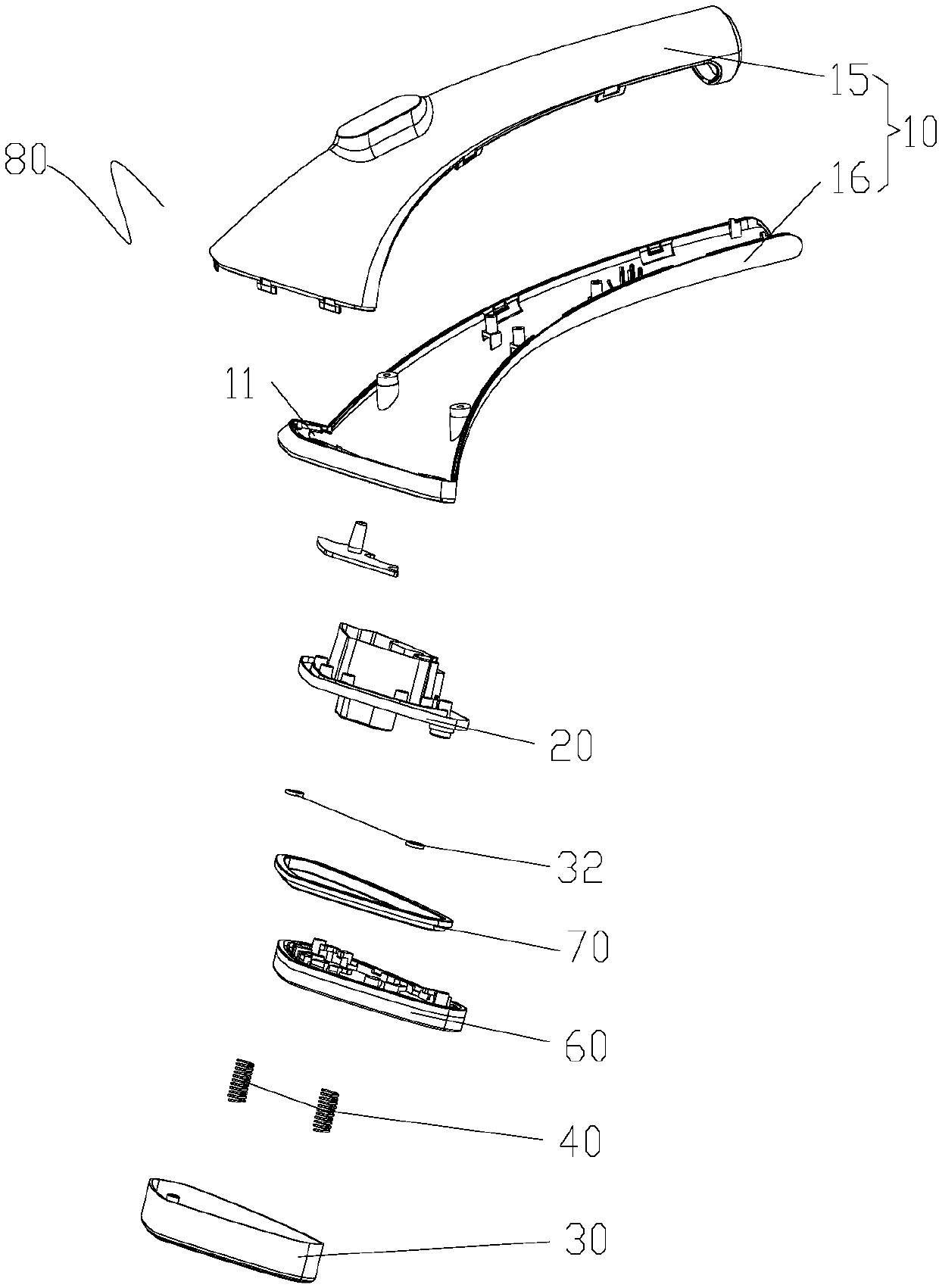

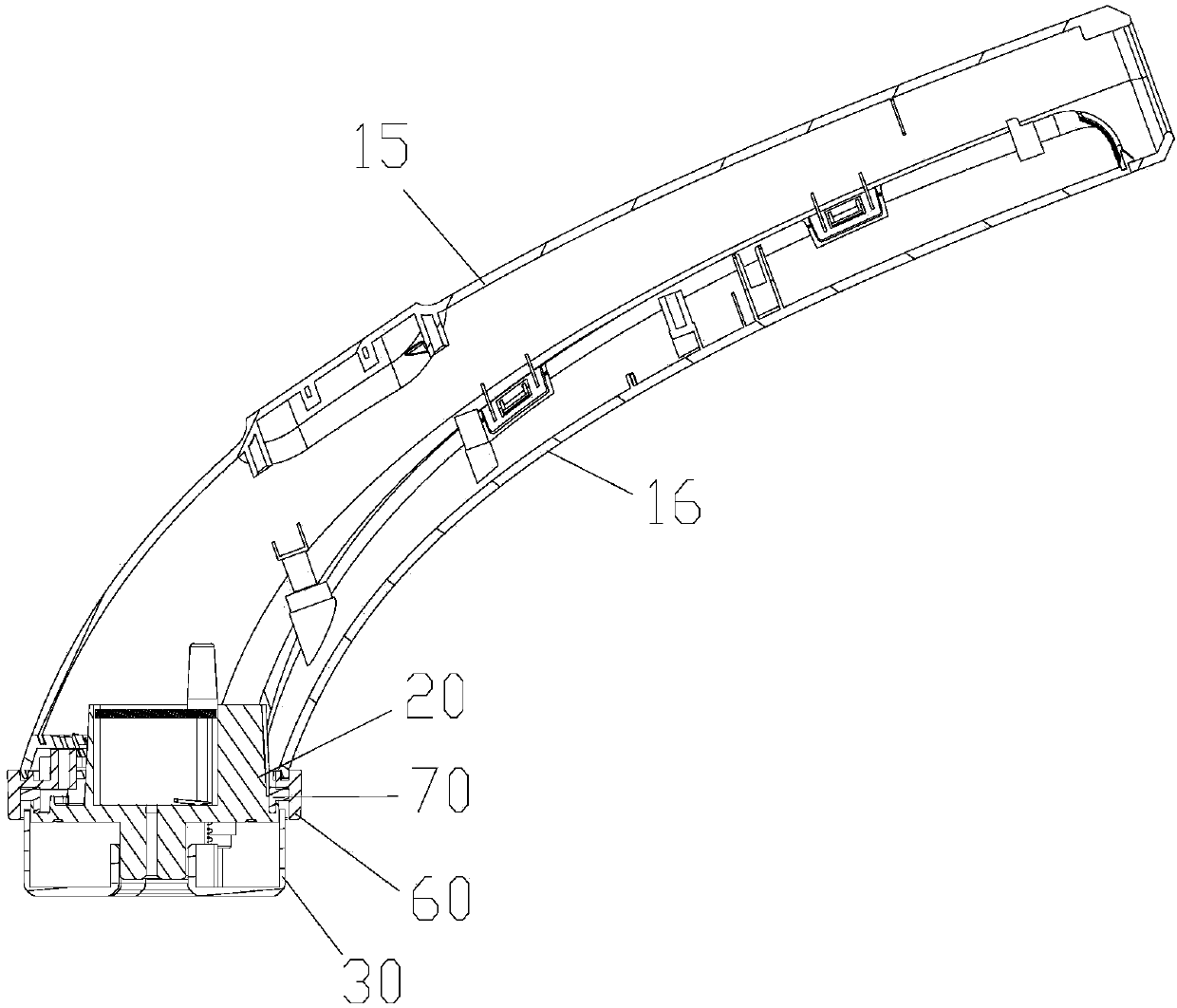

[0032] Such as figure 1 and figure 2 A steam brush head 80 shown includes a casing 10, a partition 20, a bottom plate 30 and a floating piece 40. The casing 10 has a mounting hole 11; the partition 20 is arranged in the casing 10; , and the bottom plate 30 and the partition 20 enclose a vaporization chamber; the floating member 40 is arranged between the bottom plate 30 and the partition 20 so that the bottom plate 30 can change the extension distance of the bottom plate 30 relative to the installation hole 11 when it is subjected to an external force.

[0033] Specifically, the floating member 40 between the bottom plate 30 and the partition 20 enables the relative position between the bottom plate 30 and the partition 20 to change, and when the bottom plate 30 contacts the clothing, the relative position can be adjusted according to the degree of contact with the clothing, ensuring The close contact between the bottom plate 30 and the clothes ensures a good ironing effect....

Embodiment 2

[0054] The difference from Embodiment 1 is that the separator 20 is a vaporization body, so that the steam brush head 80 has the function of secondary vaporization.

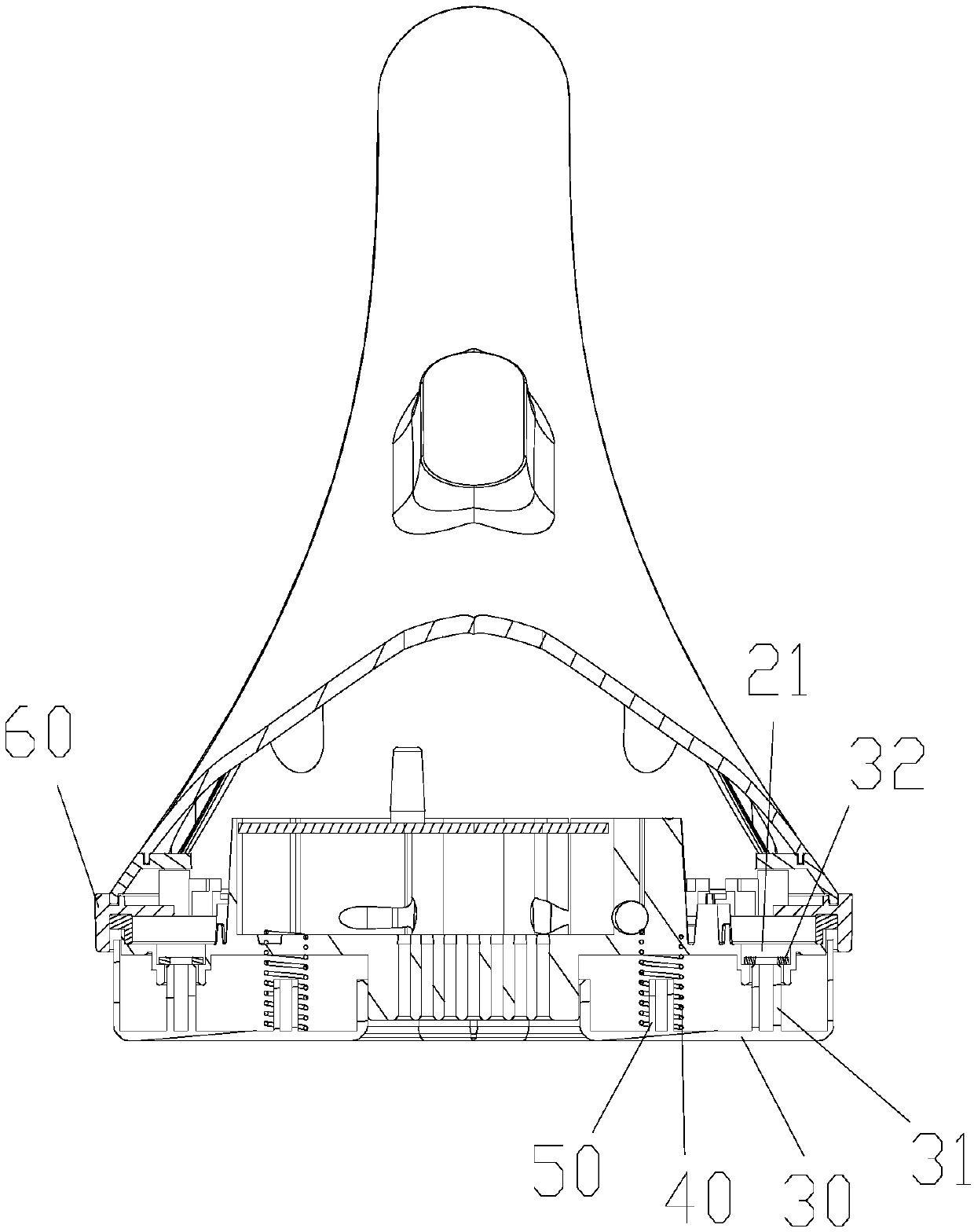

[0055] Such as Figure 4 to Figure 6 As shown, the side of the partition 20 facing away from the bottom plate 30 has a protruding structure, and the protruding structure has a cavity for accommodating the heating element.

[0056] In this embodiment, the steam brush head 80 also includes a heating element partially arranged in the partition 20, the heating element is a heating tube 22, more specifically an electric heating tube, and the heating tube 22 is used to control The steam is reheated to achieve secondary vaporization. A vaporization chamber cover 23 is provided at the end of the cavity away from the vaporization chamber. The vaporization chamber cover 23 seals the cavity to prevent steam from overflowing, and at the same time, it can facilitate the installation and replacement of the heating tube 22 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com