A connector for connecting metal pipes

A technology of metal pipes and connectors, applied in the direction of pipes/pipe joints/fittings, flange connections, pipes, etc., can solve the problems of low pressure bearing capacity, affecting the service life of pipes, and poor sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

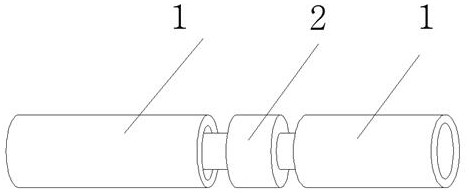

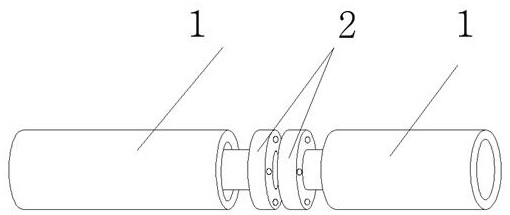

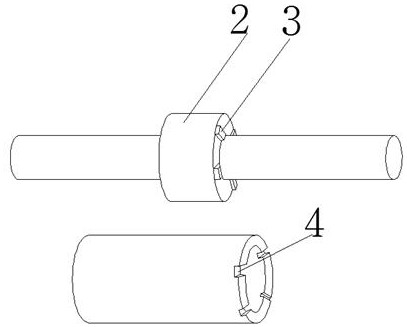

[0042] like Figure 1-7 Shown: a method for connecting steel pipes 1, the interface ends of two steel pipes 1 are connected by connecting bolts, the interface ends of steel pipes 1 are heated and rotated, and inner necks are formed through necking processing, and the inner necks are thickened toward the inward flanging of steel pipes 1 An inner notch 5 is formed, and an inner thread is arranged in the inner constriction, and the inner thread is respectively connected to two ends of the connecting bolt.

[0043] The inner necking process is to fix the workpiece on the fixture first, and heat the processing end of the workpiece. The heating temperature range is 500-1800 ° C. While heating, the workpiece is rotated, so that the workpiece is in contact with the inner necking processing mold and moves relatively. The end is extruded and flanged, and the processing end is shaped at the same time. The inner shrinking processing mold is made of hard material, and the workpiece rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com