An optical waveguide group refractive index testing device and method

A group refractive index and testing device technology, which is applied in measuring devices, optical instrument testing, and refractive power measurement, can solve problems such as difficult group refractive index Ng testing, large group refractive index errors, and large testing errors, so as to improve testing The effect of flexibility, reducing test error and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

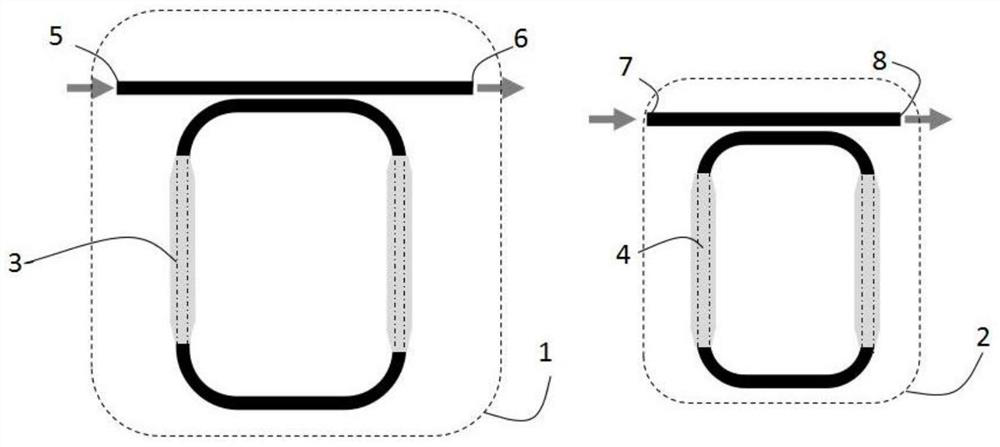

[0085] like figure 1 As shown in the figure, the light beams are respectively injected from the direct wave guide entrance port 5 of the first micro-ring test assembly 1 and the direct wave guide entrance port 7 of the second micro-ring test assembly 2, and are coupled into the micro-ring test assembly through the directional coupler. After the sub-cycle coupling, it is emitted from the straight-wave exit port 6 of the first micro-ring test assembly 1 and the direct-wave exit port 8 of the second micro-ring test assembly 2; respectively, the test spectra of the two micro-ring test assemblies are obtained, and from the spectra get the resonant wavelength λ 1 and its corresponding FSR 1 (λ) relationship and resonant wavelength λ 2 and its corresponding FSR 2 (λ) relationship: FSR∝λ. Finally, the group refractive indices Ng of the first waveguide 3 to be tested and the second waveguide 4 to be tested are calculated and obtained.

[0086] In this embodiment, a fully etched st...

Embodiment 2

[0089] like figure 1 As shown in the figure, the light beams are respectively injected from the direct wave guide entrance port 5 of the first micro-ring test assembly 1 and the direct wave guide entrance port 7 of the second micro-ring test assembly 2, and are coupled into the micro-ring test assembly through the directional coupler. After the sub-cycle coupling, it is emitted from the straight-wave exit port 6 of the first micro-ring test assembly 1 and the direct-wave exit port 8 of the second micro-ring test assembly 2; respectively, the test spectra of the two micro-ring test assemblies are obtained, and from the spectra get the resonant wavelength λ 1 and its corresponding FSR 1 (λ) relationship and resonant wavelength λ 2 and its corresponding FSR 2 (λ) relationship: FSR∝λ. Finally, the group refractive indices Ng of the first waveguide 3 to be tested and the second waveguide 4 to be tested are calculated and obtained.

[0090]In this embodiment, a shallow etched r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com