Air pressure balance compensator used in rolling type air excitation negative pressure system

A technology of air pressure balance and balance compensation, which is used in auxiliary non-electrical fluid pressure control and other directions, can solve the problems of complex structure and large space occupation, and achieve the effect of simple and compact structure, small space occupation and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] As a basic example:

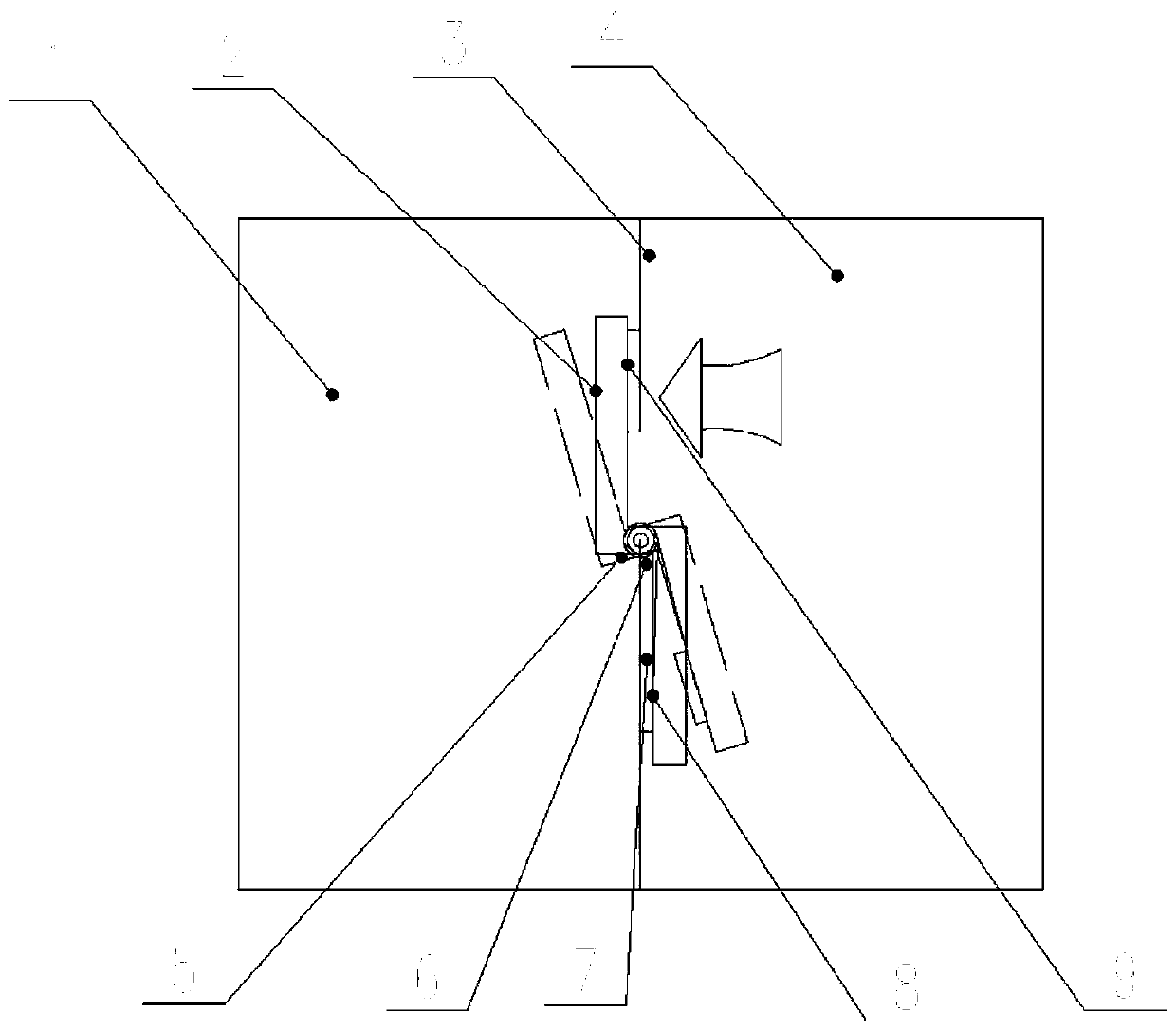

[0027] The air pressure balance compensator used in the rolling air excitation negative pressure system includes an air pressure mechanism, and the air pressure mechanism is divided into a low air pressure chamber 1 and a high air pressure chamber 4. It is characterized in that the low air pressure chamber 1 and the high air pressure chamber 4 A balance compensator main body 2 is installed between them, and it is characterized in that a main body support 5 is installed in the center of the balance compensator main body 2, a balance compensator spring 6 is installed on the main body support 5, and a compensating spring 6 is installed on the balance compensator main body 2. The compensator buffer pad 8 and the compensator seal pad 9 are arranged symmetrically with the central axis of the balance compensator spring 6, the compensator seal pad 9 is connected with the upper sealing layer 3, and the compensator buffer The pad 8 is connected with a lower ...

Embodiment 2

[0030] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the upper sealing layer 3 and the lower sealing layer 7 are located on the same vertical plane, and the upper sealing layer 3 is provided with a There is an opening for the communication between the low-pressure chamber 1 and the high-pressure chamber 4, the compensator gasket 9 is flexibly connected to the upper sealing layer 3, one end of the lower sealing layer 7 is fixedly connected to the inner wall of the air pressure mechanism, and the lower sealing layer 7 The other end is hinged at the center of the main body support 5 .

[0031] The pressure of the low pressure chamber 1 and the high pressure chamber 4 in the present invention all act on the upper half of the main body support 5, when the pressure of the low pressure chamber 1 is less than the set value, the pressure of the high pressure chamber 4 pushes the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com