High-temperature region signal detection device and casting blank counting method

A technology of signal detection and counting methods, applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve problems such as damage to PLC templates, disordered PLC control, and inability to realize billet statistical functions, etc., and achieve improved standards Refinement and product quality, to ensure the effect of continuous casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

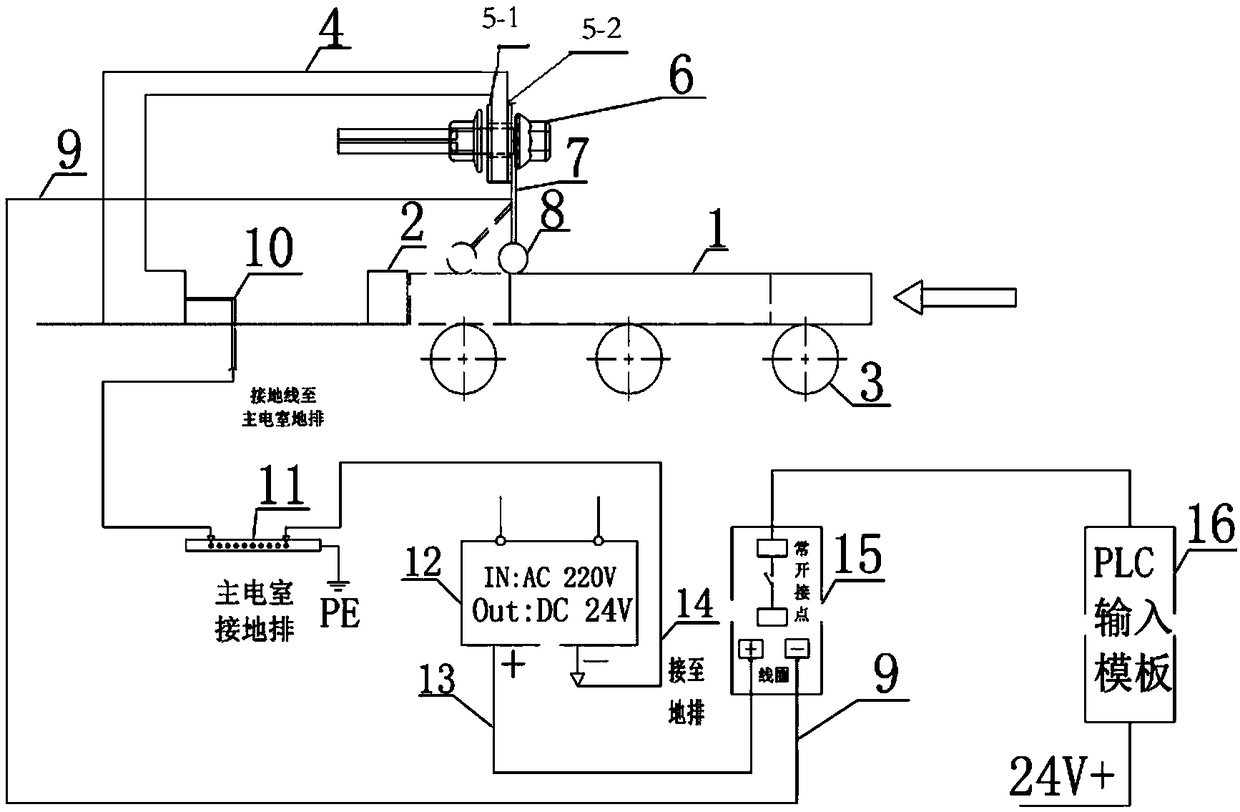

[0020] A signal detection device in a high-temperature area, comprising a cantilever hanging ball-type limiting device 4 and a control circuit, the forearm of the cantilever-hanging ball-type limiting device 4 is connected to a movable hanging ball 8 with a high-temperature-resistant flame-retardant cable 7, and the resistant The length of the high-temperature flame-retardant cable 7 ensures that the movable hanging ball 8 is fully in contact with the upper surface of the cast slab 1, and the cantilever hanging ball-type limiting device 4 is connected to the corresponding terminal of the grounding row of the main electrical room; the corresponding terminals of the control circuit are respectively The corresponding terminals of the grounding bar 11 in the power connection room and the high-temperature-resistant flame-retardant cable 7; the industrial computer is connected to the control circuit through the PROFIBUS bus; the industrial computer is equipped with an HMI man-machine ...

Embodiment 2

[0031] A method for counting slabs. When a limit signal detection program is configured in a control module to detect a limit signal, the HMI man-machine control program installed in an industrial computer is notified to perform an increase counting operation and display a statistical result.

[0032] The slab counting method further includes that the HMI man-machine control program receives the input operation commands of adding, subtracting and counting back to zero, and correspondingly adds, subtracts and counts back to zero on the statistical results.

[0033] When the limit signal detection program configured in the PLC input template detects the limit signal, it will notify the HMI man-machine control program installed in the industrial computer to perform an increase counting operation and display the statistical results.

[0034] Using the original billet PLC control system, compile the statistics of the number of billets. The contact signal of the intermediate relay 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com