Finite element refinement simulation method for pipe jacking construction of pipe gallery structure

A simulation method and finite element technology, applied in the field of fine finite element simulation, numerical simulation, and pipe jacking construction of pipe gallery structure, can solve the problem that it cannot reflect the real state of pipe jacking of pipe gallery, the result has no reference value, and cannot guide the actual project and other problems, to achieve the effect of fine simulation, high versatility, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

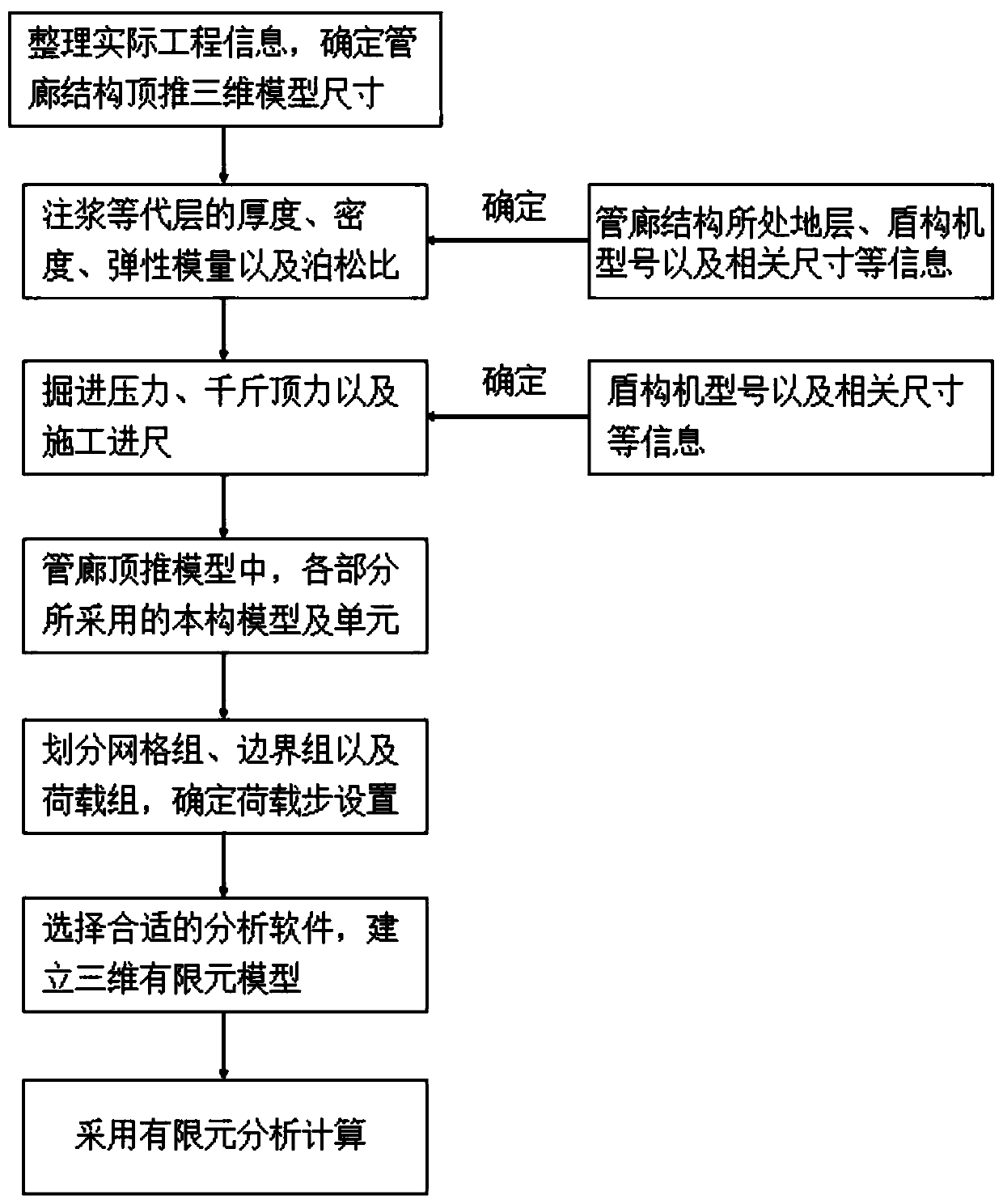

Method used

Image

Examples

Embodiment

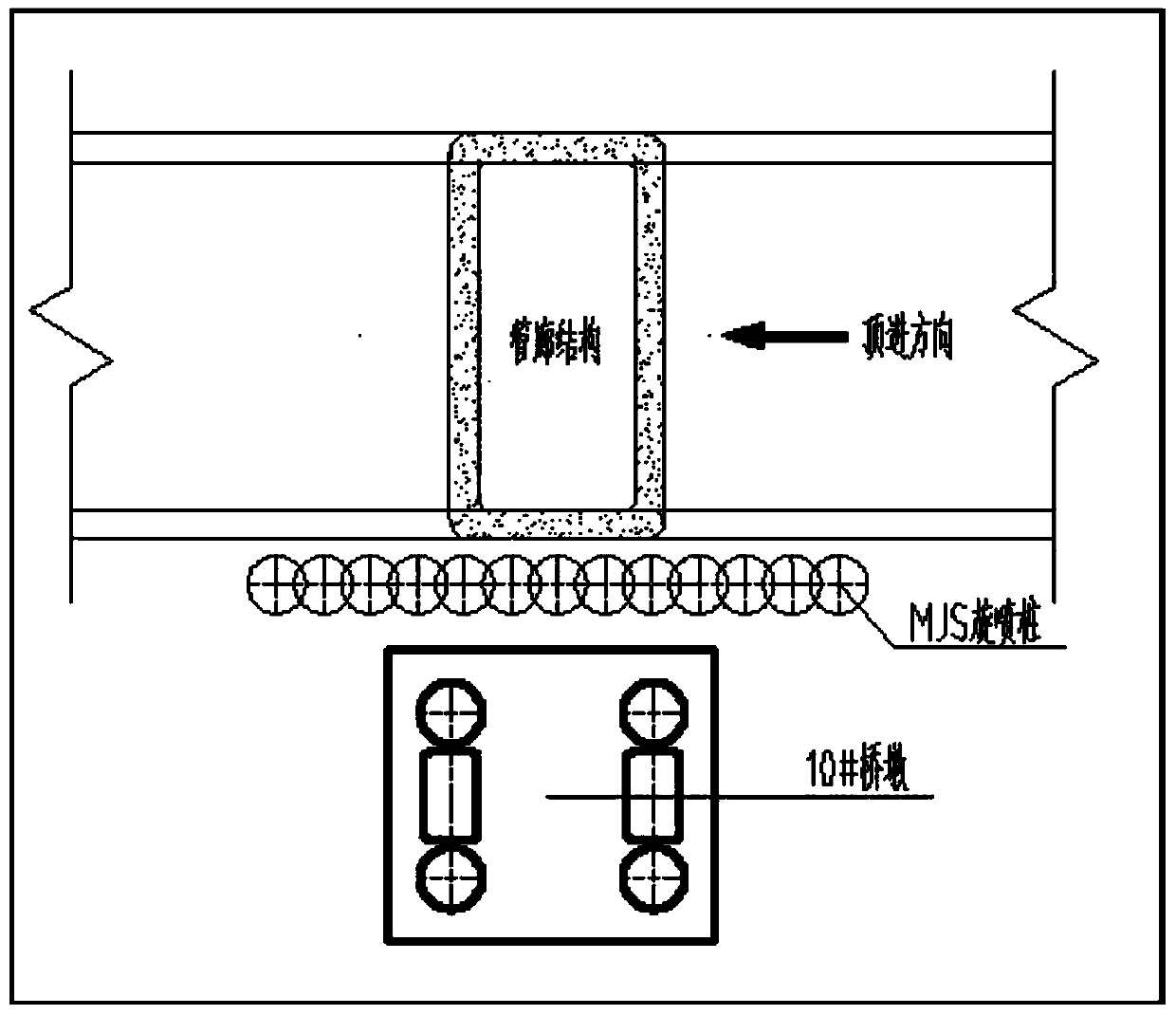

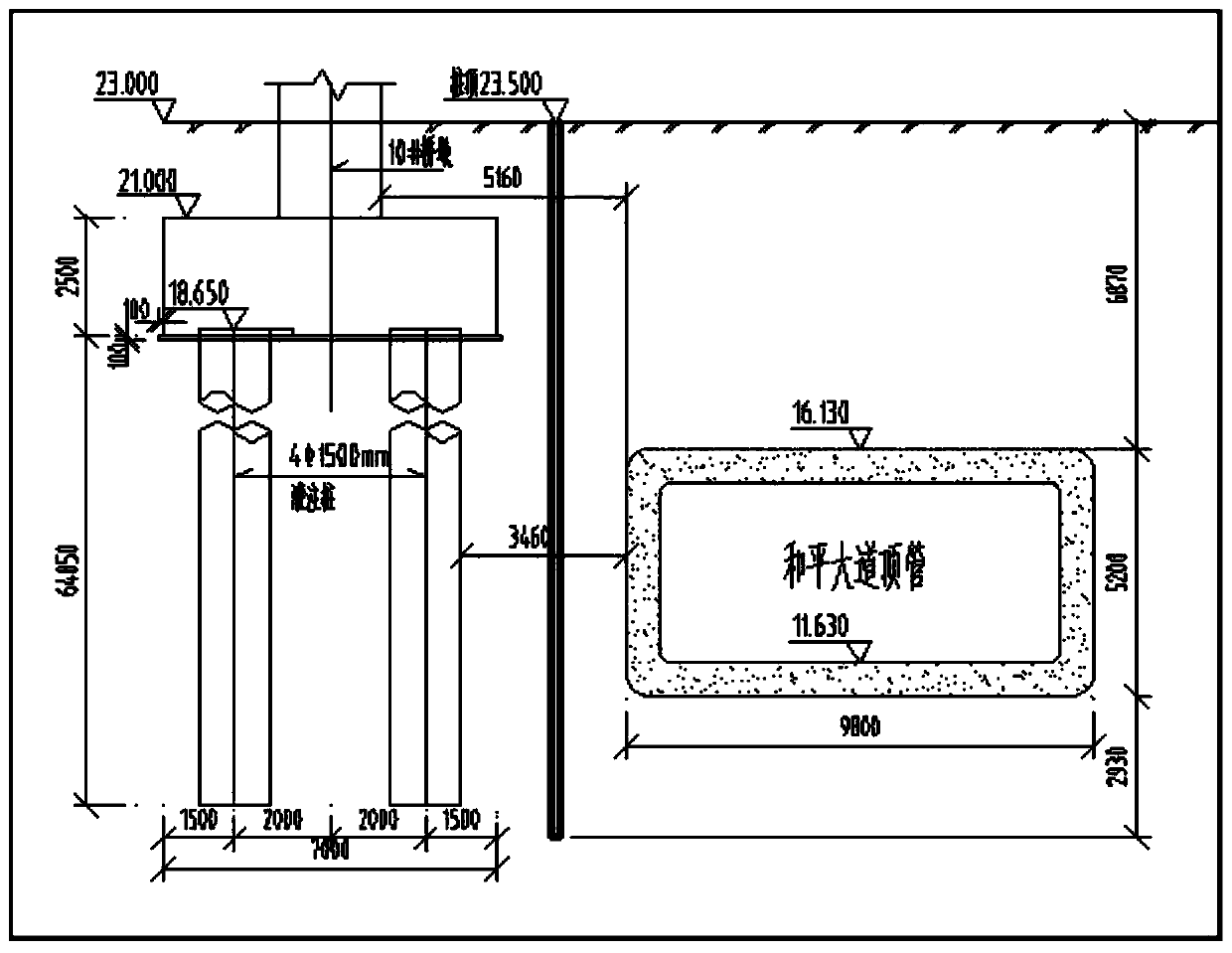

[0078] The present invention is further introduced below in conjunction with the actual engineering of the Wuhan Heping Avenue Viaduct that pushes down through the top of the comprehensive pipe gallery of the Wuhan-Nine Lines Line. The dimensions of the project example model plan and section schematic diagrams are as follows: figure 2 As shown in Figure 3, this section is a single cabin pipe gallery structure with a length of 9.8m, a height of 5.2m, a plate thickness of 0.7m, and a width of each section of 2m; the buried depth of the top of the pipe gallery structure is 6.87m, The net distance from the pile foundation of the adjacent viaduct is 3.46m, and the MJS rotary grouting piles with a length of 15m, a height of 15m and a thickness of 1.4m are installed between the pipe gallery structure and the existing bridge piles, and the net distance from the pipe gallery structure is only 0.4 m.

[0079] ① Firstly, according to the thickness of the shield shell steel plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com