Bus duct joint connecting structure

A joint connection and busway technology, which is applied in the direction of connection, fully enclosed busbar device, and parts of the connection device, can solve the problems of reduced safety, unfavorable waterproofing, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

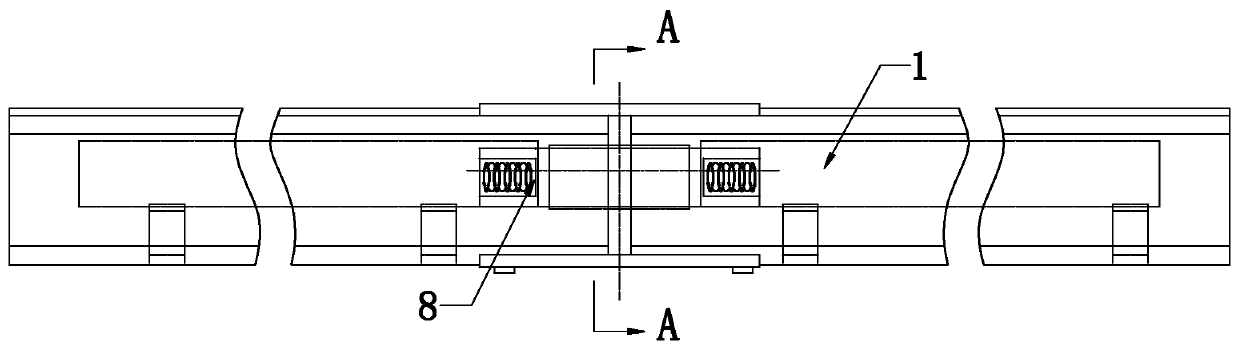

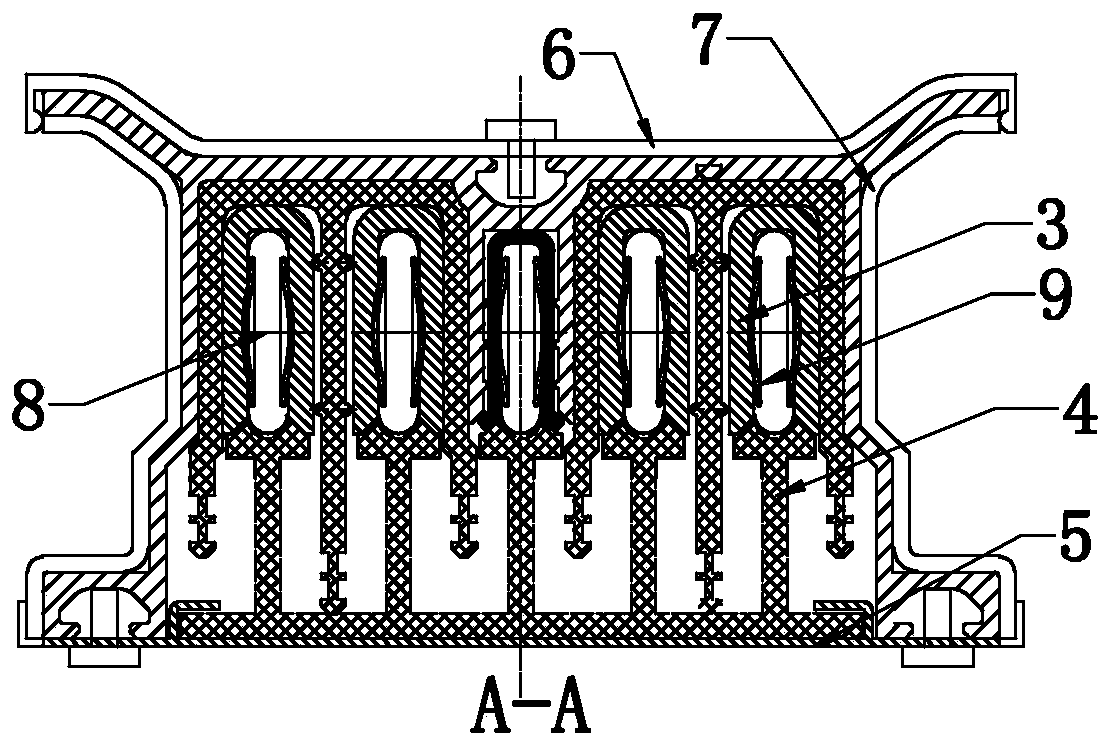

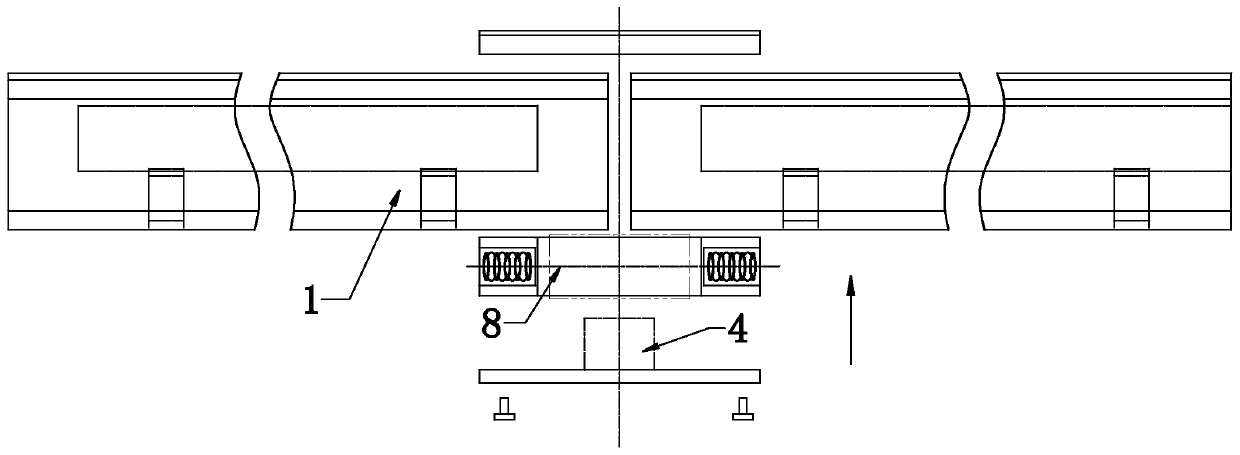

[0015] The connection structure of the bus duct joint of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] As shown in the figure, the bus duct joint connection structure of the present invention includes two bus ducts 1 to be connected and a plug-in structure for cooperating and installing the bus ducts to be connected. Both bus ducts are provided with m-shaped The U-shaped conductor 3 installed by the insulator, the busway is provided with a four-phase U-shaped conductor 3 and a grounding conductor of the same U-shaped structure. Of course, the grounding conductor is located between two m-shaped insulators to form a single and The installation part where the shell contacts, the plug-in structure 2 includes an insulating bracket 4 arranged with supporting arms and a plug-in conductor 8 supported by the insulating bracket. It can be seen from the figure that the supporting arm on each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com