Descaling mechanism and fish belly and back descaling device

A fish belly and rack technology, used in fish processing, fish cleaning/descaling, slaughtering, etc., can solve the problem of inability to remove fish back or fish belly scales, and achieve the effect of improving processing quality and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

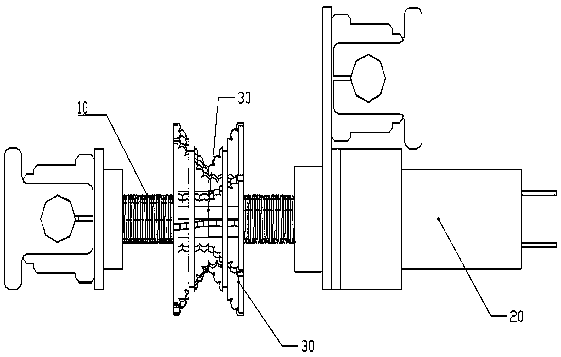

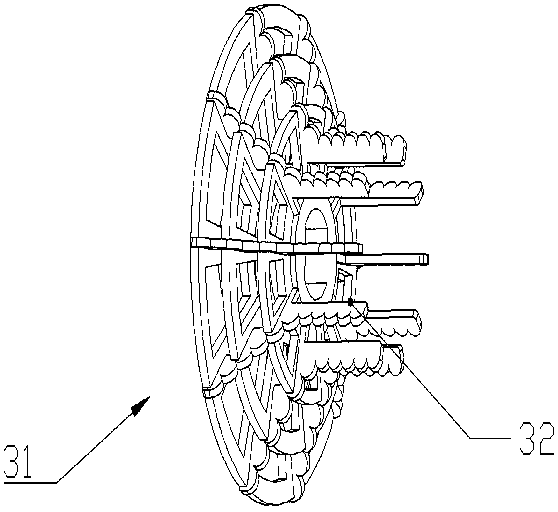

[0030] Embodiment 1: a kind of descaling mechanism, see figure 1 with figure 2 , including transmission shaft 10, descaling motor 20 and descaling device 30, descaling 30 includes two umbrella-shaped descaling hobs 31 opposite to its cone top that is axially slidably installed on the transmission shaft 10, two descaling rollers The tapered tops of the knife 31 extend toward each other to form a sliding fit (in this example, the scaling blade is extended) to adapt to the thickness of the fish back or / and the fish belly. The descaling hob 31 includes an umbrella-shaped hollow type runner and The scraper blade 32 that is arranged on this runner umbrella peripheral surface, runner is made of a plurality of diameter gradually smaller, coaxial wheel discs and fixed spokes thereof. Through holes are arranged on the runner to form an umbrella-shaped hollow runner. Scaling blade 32 comprises installation base and descaling blade, and installation base matches with the shape of runne...

Embodiment 2

[0031] Embodiment 2, a kind of descaling mechanism, see figure 1 with figure 2 , the difference from Example 1 is that the scale scraping blade is replaced by a scale scraping strip brush (including an installation base and a descaling brush part made of steel material), and the others are basically the same.

Embodiment 3

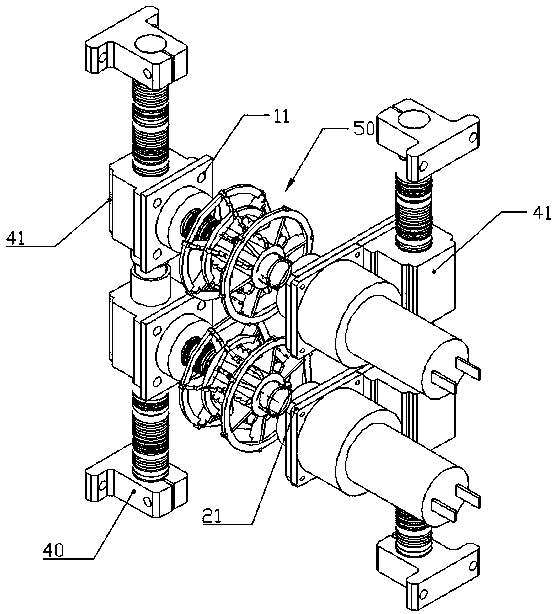

[0032] Embodiment 3: A kind of device for removing scales from the belly and back of fish, see image 3 with Figure 4 , including two descaling mechanisms 50 and a frame 40, the two descaling mechanisms 50 are installed on the frame 40 in parallel up and down, the descaling motor 20 is fixed on the motor fixing frame 21 by bolts, and the transmission shaft 10 is fixed by bolts Installed on the drive shaft fixed frame 11, the two ends of the descaling mechanism can slide up and down on the support rod of the frame through the sliding pair, so that a variable gap that fits the fish body is formed between the two descalers 30, so that The fish scales on the belly and the back of the fish can be removed more cleanly, and the scale removal device on the belly and back of the fish can be adapted to fish of different sizes. The sliding pair includes a sliding block 41 sleeved on the support rod and a spring in a compressed state, and the motor fixing frame 21 and the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com