Embedded type steam oven and installation method thereof

A steam oven and embedded technology, which is applied in the direction of steam cooking utensils, roasters/barbecue grids, household appliances, etc., can solve the problems of box damage, parts damage, and steam ovens that cannot be used normally, so as to increase stability, The effect of reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

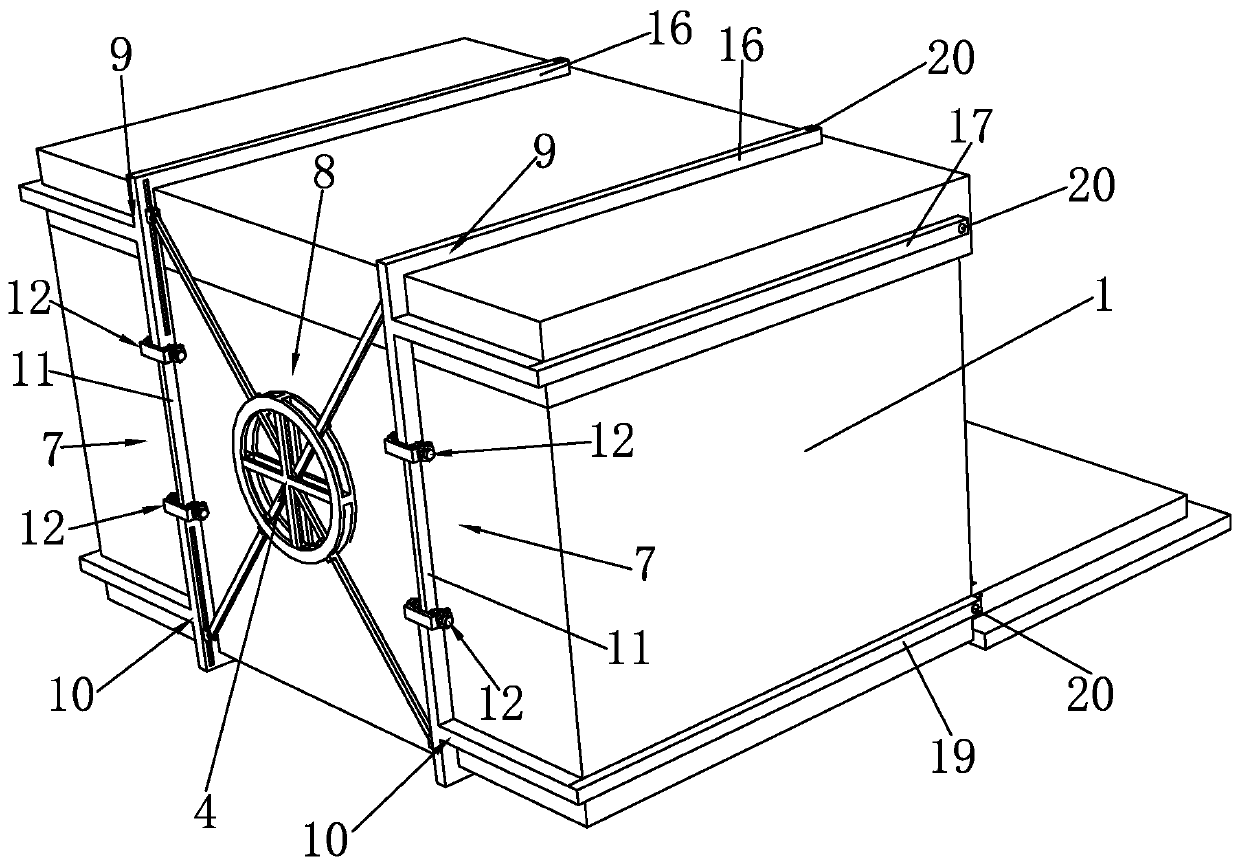

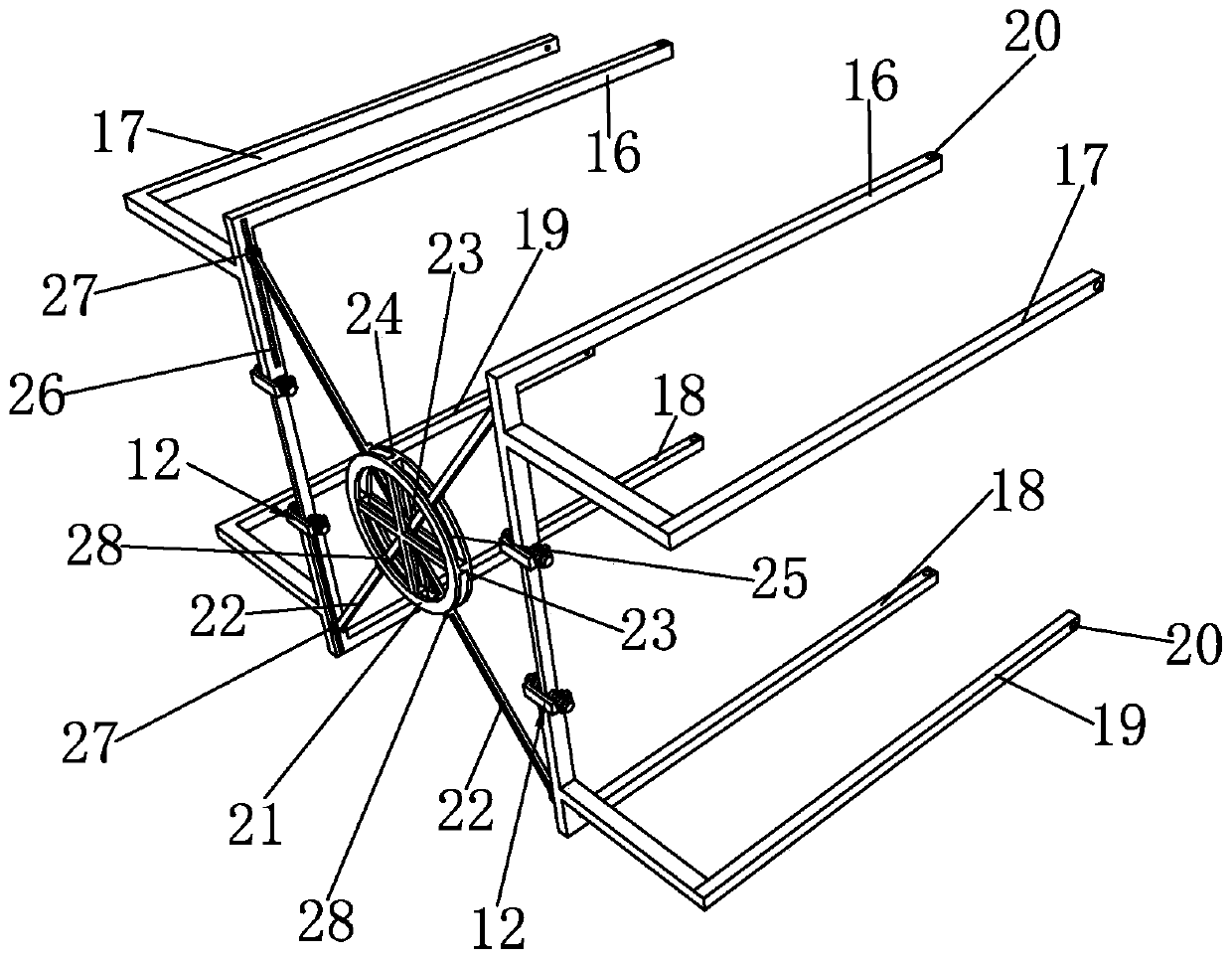

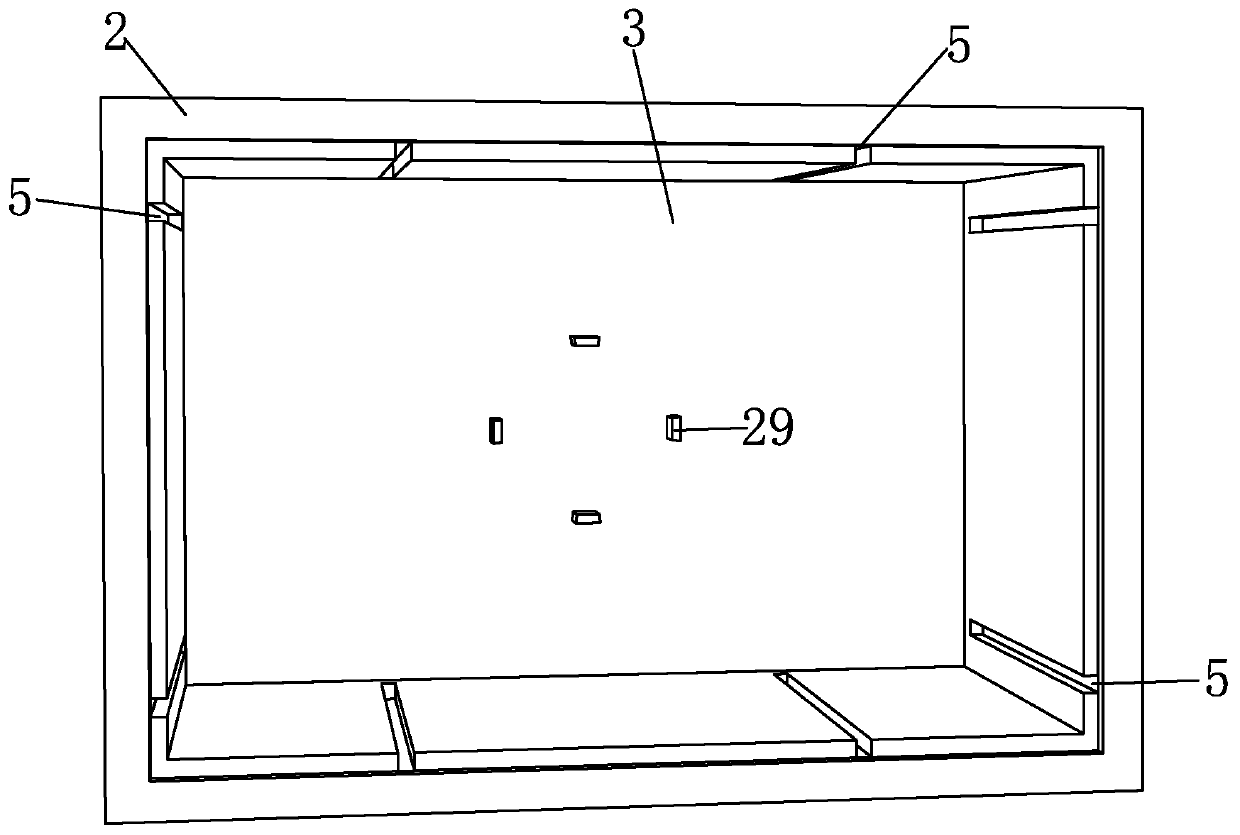

[0048] Such as Figure 1 to Figure 5 As shown, it is a built-in steaming oven of the present invention, which includes a box body 1 and a mounting part 2. The mounting part 2 is provided with a mounting groove 3, and an adjustable clamping mechanism 4 is provided on the outside of the box body 1, and the clamping mechanism 4 can be adjusted. The mechanism 4 clamps the box body 1 , and both the adjustable clamping mechanism 4 and the box body 1 are embedded in the installation groove 3 .

[0049] The inner walls of the mounting grooves 3 are provided with chute 5 , and the chute 5 is matched with the adjustable clamping mechanism 4 . During the installation process of the box body 1, the adjustable clamping mechanism 4 is first aligned with the chute 5, and then the adjustable clamping mechanism 4 is inserted into the chute 5, and the box body 1 is installed along the direction of the chute 5 installation groove 3, thereby ensuring that both sides of the box body 1 can be load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com