Servo control complete equipment

A complete set of equipment and servo control technology, applied in the field of servo control, can solve the problems of impact, constant work efficiency, single operation mode, etc., and achieve the effect of reducing the damage rate and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

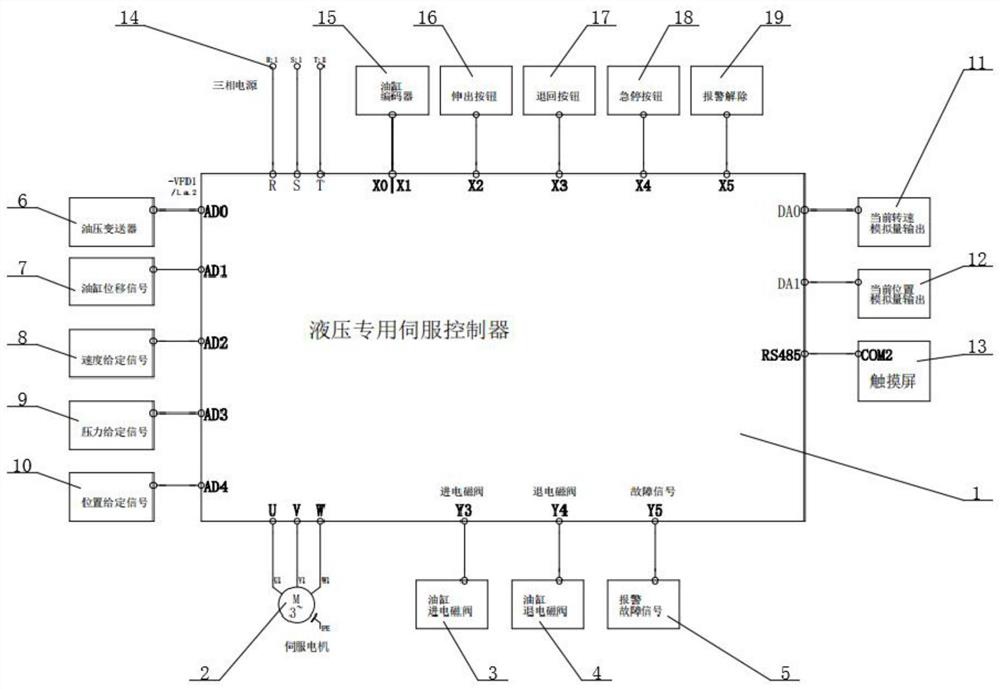

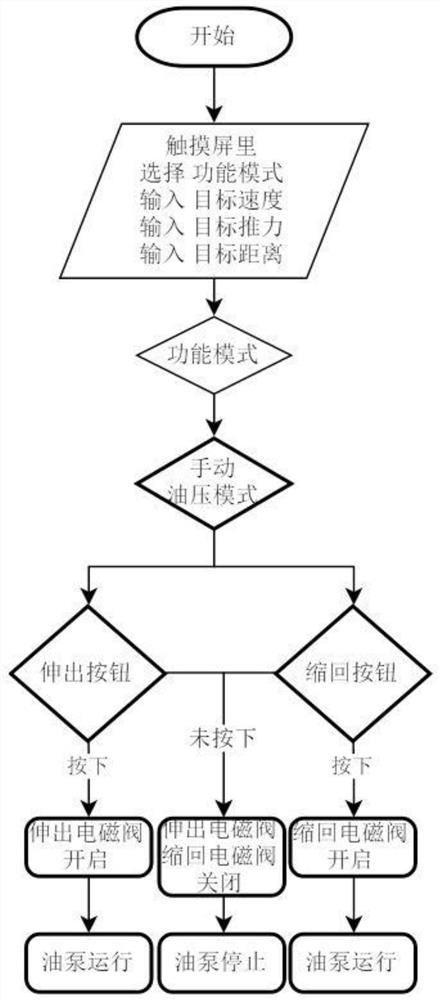

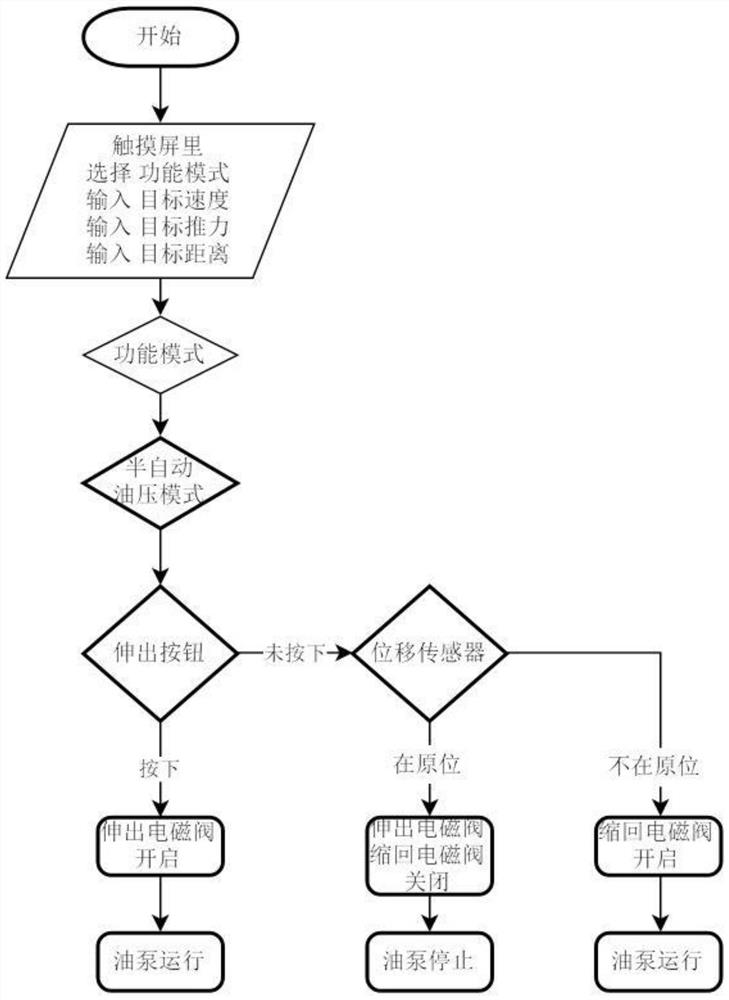

[0029] see Figure 1-9 , the present invention provides a technical solution:

[0030] The complete set of servo control equipment includes a hydraulic special servo controller 1, and the bottom side of the hydraulic special servo controller 1 is provided with a servo motor 2, an oil cylinder inlet solenoid valve 3, an oil cylinder back solenoid valve 4 and an alarm fault signal port 5. The end of the main shaft of the servo motor 2 is provided with an internal gear pump 20, and the internal gear pump 20 is coaxially connected with the servo motor 2, and one side of the servo motor 2 is electrically connected to a servo drive controller. One side of the hydraulic dedicated servo controller 1 is fixedly connected with an oil pressure transmitter 6, a cylinder displacement signal port 7, a speed given signal port 8, a pressure given signal port 9 and a position given signal port 10. One end of the transmitter 6 is electrically connected to a pressure sensor 21, the oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com