Steaming and baking box control method and device, and steaming and baking box

A control method and a technology of a control device, which are applied to roasters/barbecue grids, kitchen utensils, household utensils, etc., can solve problems such as water accumulation, and achieve the effect of improving user experience and user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

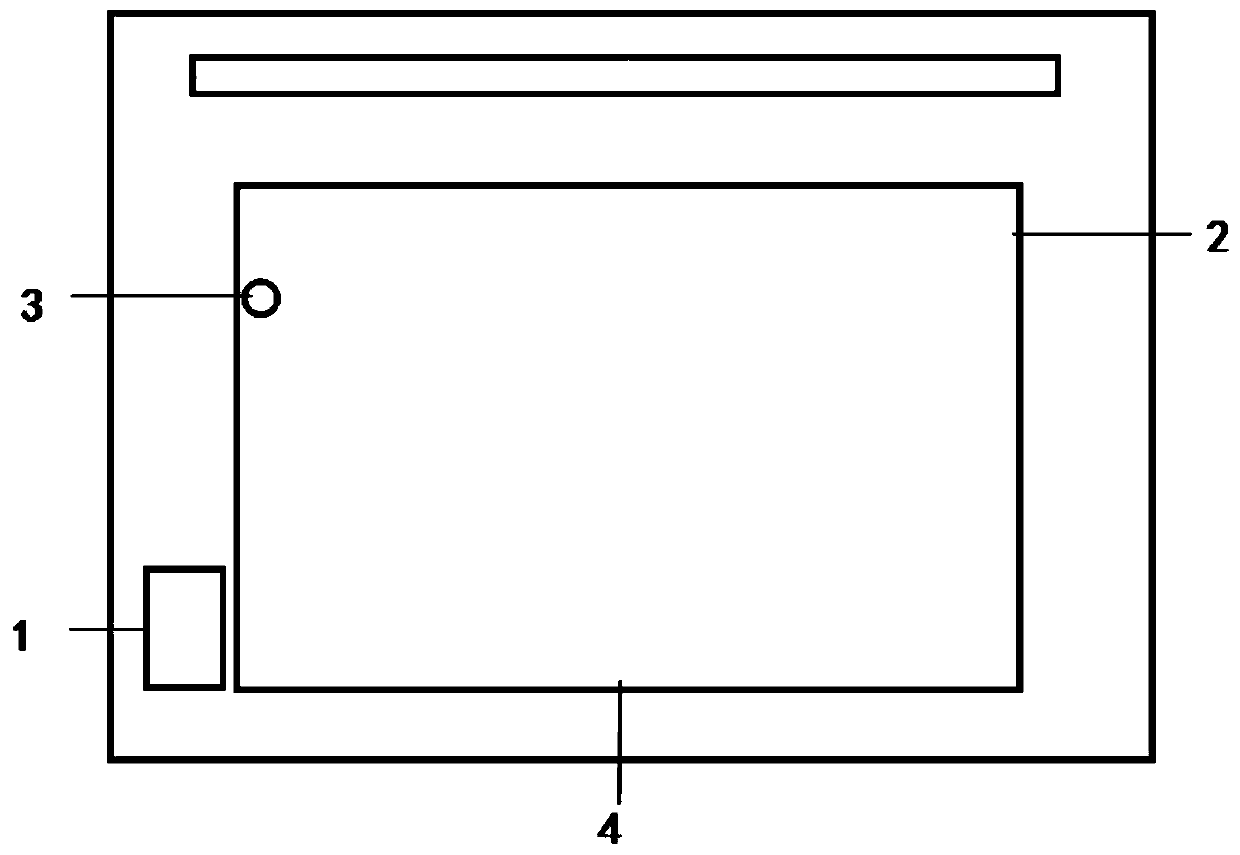

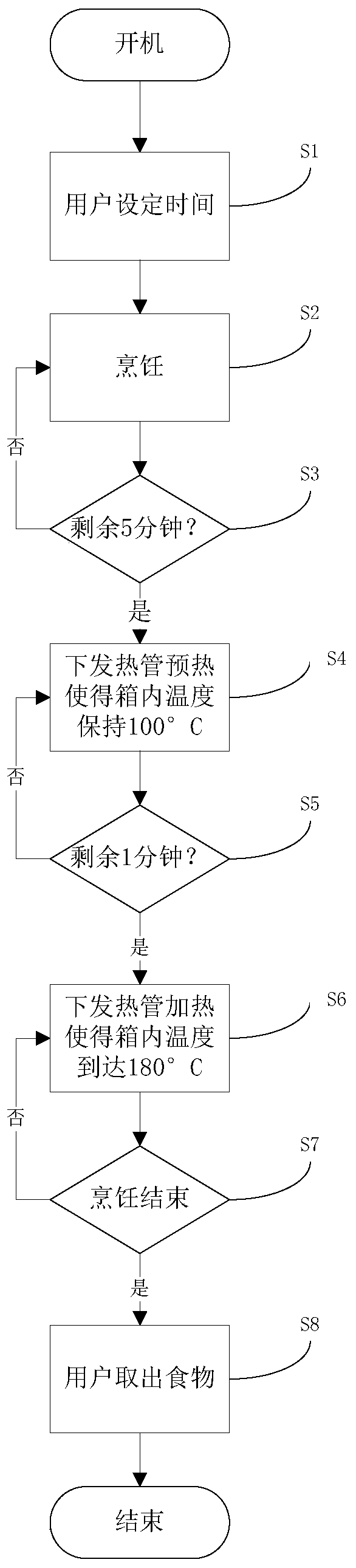

[0043] like figure 2 As shown, a steaming oven of the present invention includes a steam generator 1 , a cavity 2 , a steaming pan (not shown, for placing food), a temperature sensor 3 and a lower heat pipe 4 located in the cavity. The steam generator is located inside the cavity for generating high-heat steam; the lower heat pipe is located between the steaming pan and the cavity for generating high-temperature heat. The steam generator and the lower heat pipe work together on the food to achieve the effect of both steaming and roasting. Inside the wall of the steam oven, a temperature sensor is arranged to detect and monitor the temperature of the cavity. The temperature sensor can be located in the upper part of the cavity, or in the lower part of the cavity, in the middle of a certain surface of the cavity, or in a corner, although the accompanying drawings of the present invention show that it is in a certain position, but in the art As known to those skilled in the ar...

Embodiment 2

[0060] like Figure 4 As shown, a steaming oven of the present invention includes a steam generator 1, a cavity 2, a steaming pan (not shown, for placing food), a temperature sensor 3 and an infrared heating tube 4 located in the cavity. The steam generator is located inside the cavity and is used to generate high-heat steam; the infrared heating tube is a heating element other than the common heating components such as the upper heating tube and infrared heating tube included in the prior art, which is independently set and located on the steaming tray Between the cavity and the cavity, it is used to generate high temperature heat. Inside the wall of the steam oven, a temperature sensor is arranged to detect and monitor the temperature of the cavity. The temperature sensor can be located in the upper part of the cavity, or in the lower part of the cavity, in the middle of a certain surface of the cavity, or in a corner, although the accompanying drawings of the present inven...

Embodiment 3

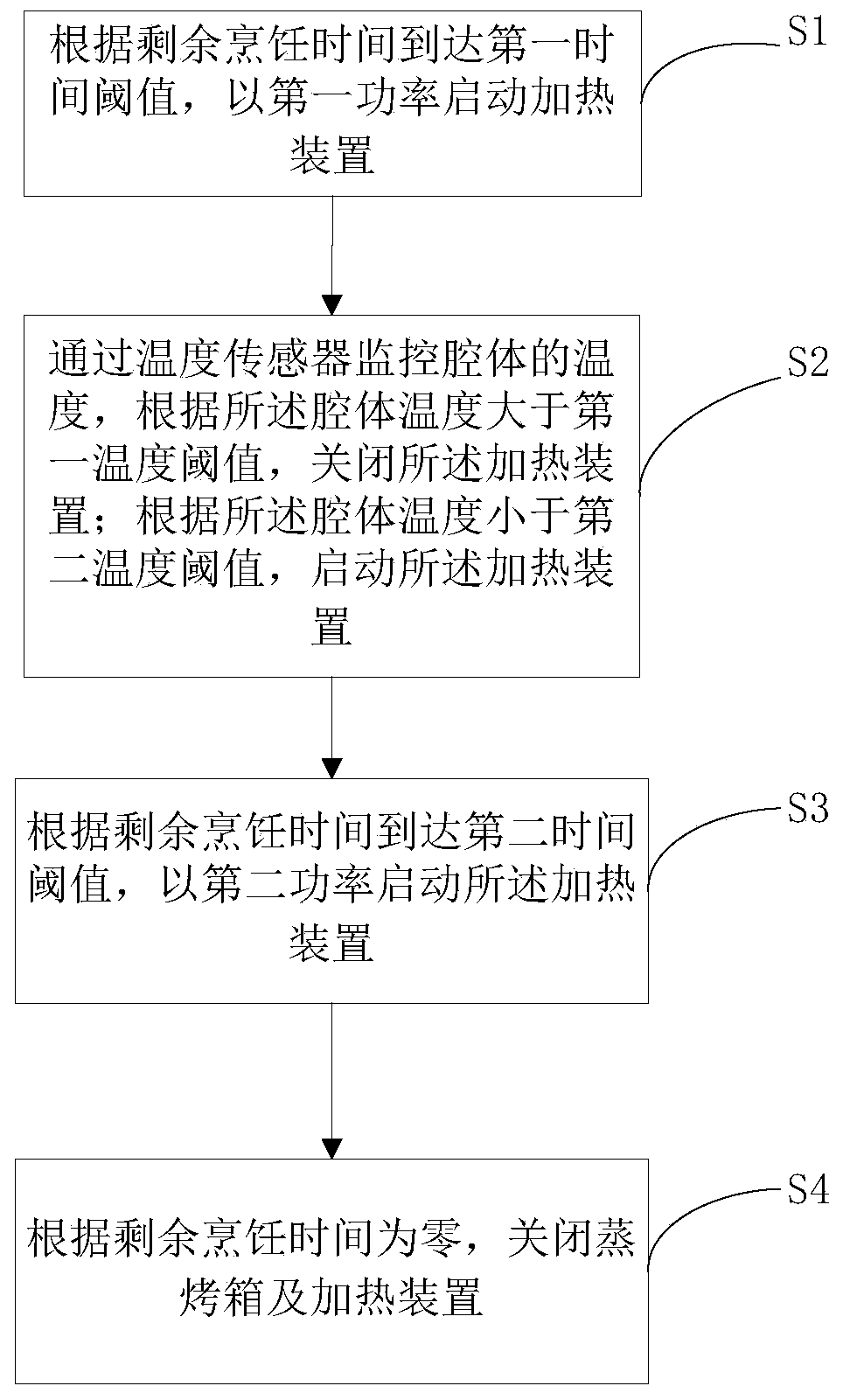

[0075] like Image 6 As shown, this embodiment provides a steam oven control device 100, which is used in a steam oven. The cavity of the steam oven includes a temperature sensor and a heating device. When the first time threshold is reached, start the heating device with the first power; the temperature control module 102 is used to monitor the temperature of the cavity through the temperature sensor, and turn off the heating device according to the temperature of the cavity being greater than the first temperature threshold; The second temperature threshold is to start the heating device; the second starting module 103 is configured to start the heating device with the second power according to the remaining cooking time reaching the second time threshold. The shutdown module 104 is configured to shut down the steam oven and the heating device according to the remaining cooking time being zero.

[0076] In some embodiments of the present invention, the heating device is a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com