Electric rotary mop

A technology of electric rotation and mop, which is applied to manual sweeping machines, carpet cleaning, floor cleaning, etc. It can solve the problems of poor cleaning effect of stubborn stains, reduce the number of times to replace the cleaning head and improve cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

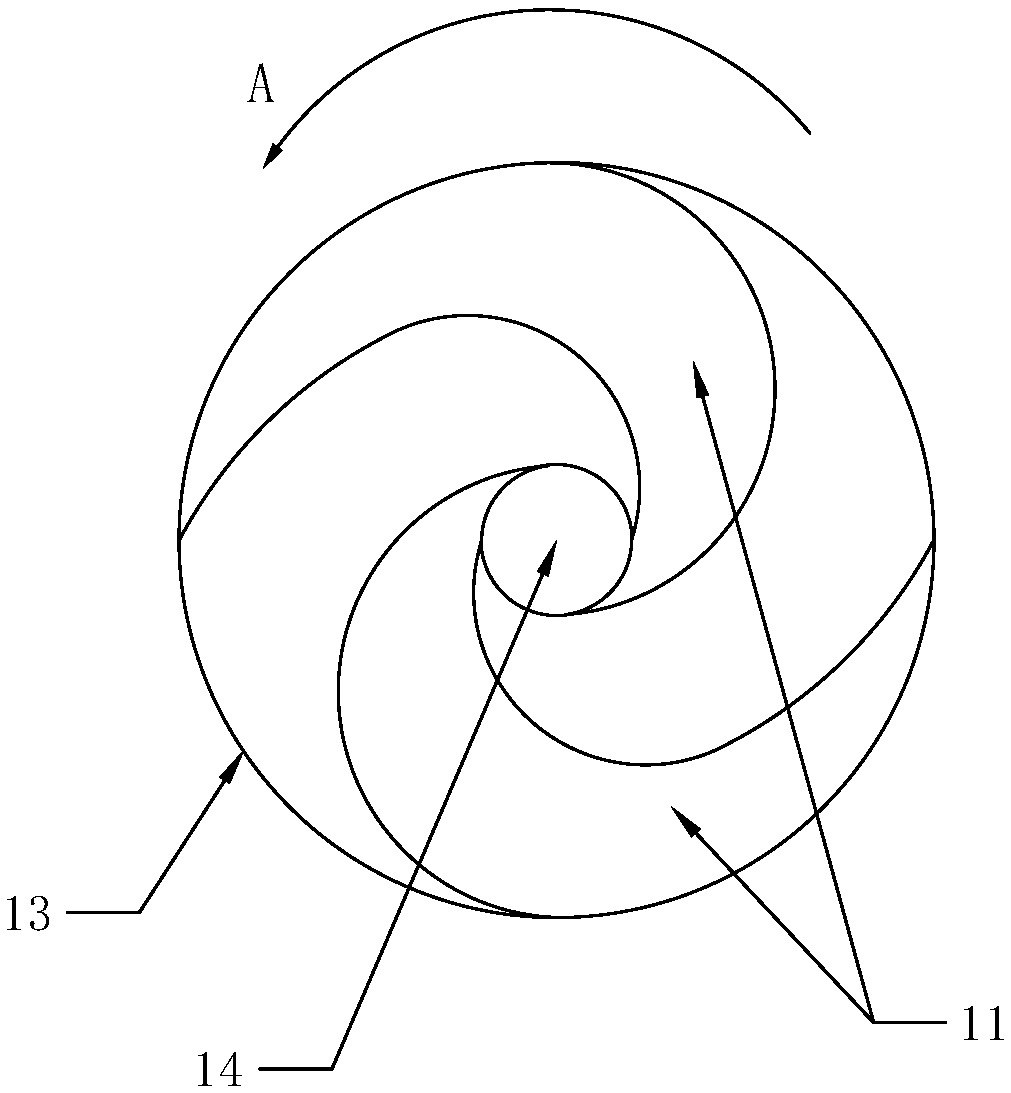

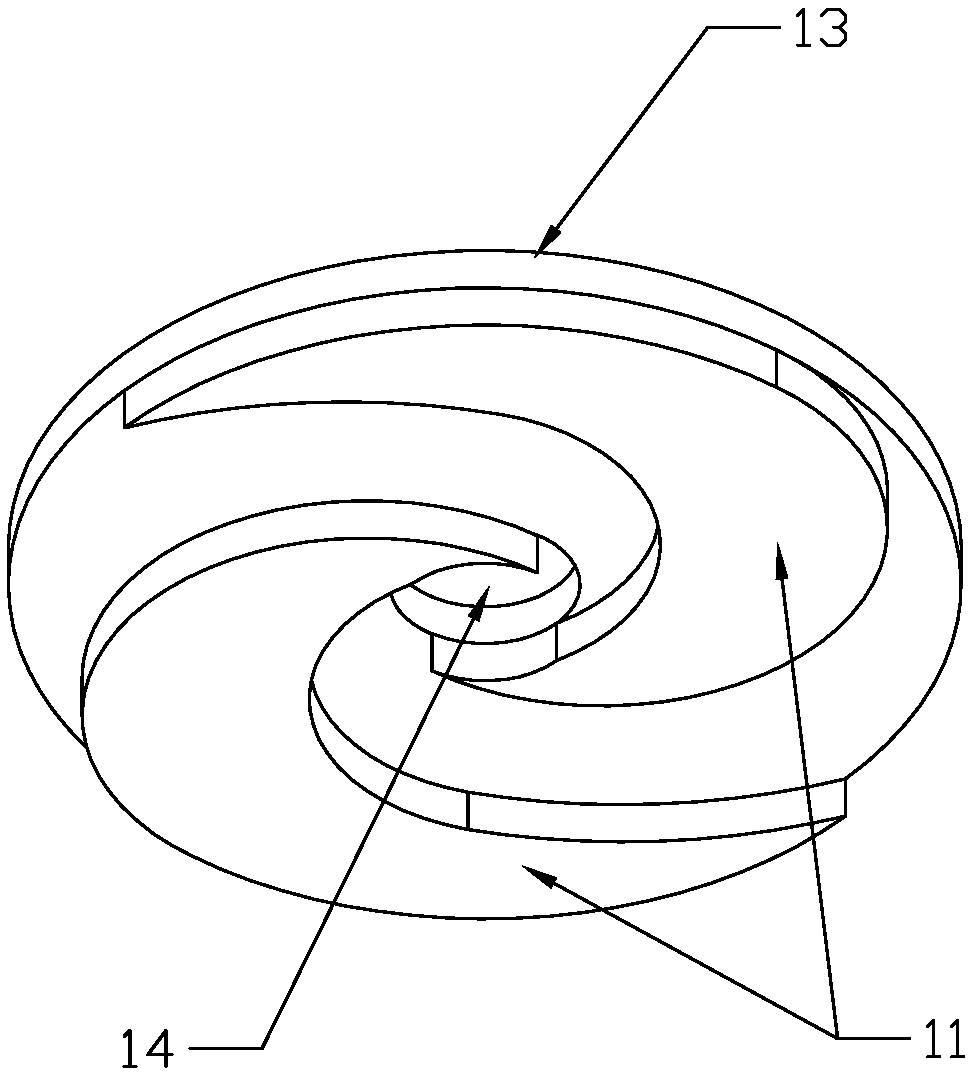

[0027] Example 1: Such as figure 1 , figure 2 As shown, the cleaning head has an impeller structure and includes two circumferentially distributed cleaning blades 11 for wiping the surface to be cleaned. In this embodiment, the direction of rotation of the cleaning head is figure 1 As shown by the middle arrow A, the cleaning blade 11 is bent toward the direction of rotation of the cleaning head; the cleaning head also includes an upper cover 13, and the cleaning blade 11 is arranged under the upper cover 13, and the center of the upper cover 13 is provided for installation positioning or dust suction The through hole 14 of the channel; in this embodiment, the material of the cleaning blade and the upper cover is a flexible absorbent wipe material, specifically preferably an integrated polyvinyl alcohol rubber cotton material, suitable for wet mopping, and can be used to clean the ground, glass, etc. Surface, and has good water absorption;

[0028] In the present invention, the i...

Embodiment 2

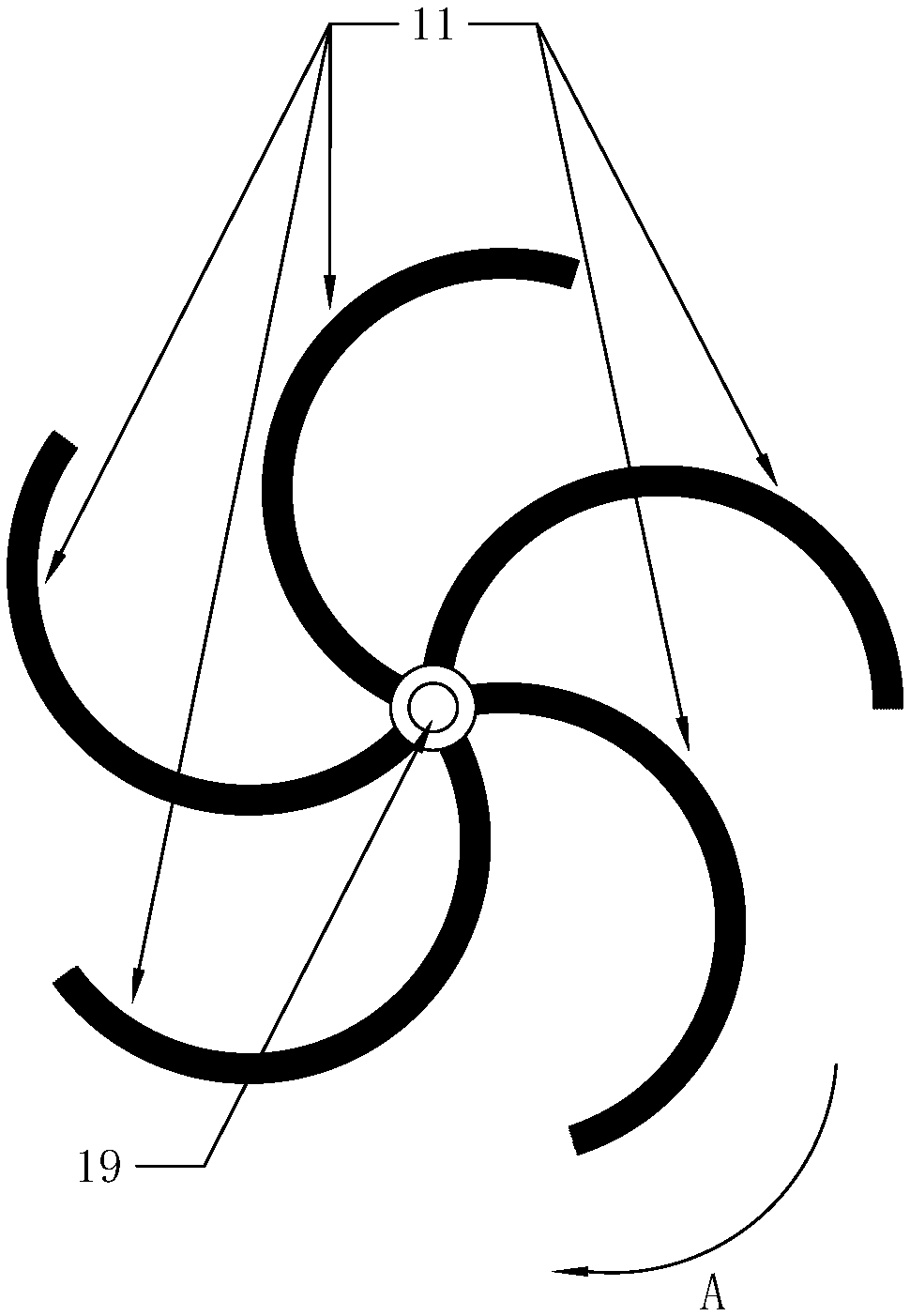

[0029] Example 2: Such as image 3 As shown, the cleaning head has an impeller structure and includes a plurality of cleaning blades 11 distributed circumferentially around the central axis 19 for cleaning the surface to be cleaned; the direction of rotation of the cleaning head is image 3 As shown by the middle arrow A, the cleaning blade 11 is bent toward the direction of rotation of the cleaning head; the cleaning blade 11 is composed of a bundle of bristles, which can be natural or artificial bristles. In order to better maintain the shape of the brush bundle, An elastic steel wire or elastic plastic strip for shaping can be arranged in the brush bundle; the cleaning head in this embodiment is mainly used as a hand-push sweeper or a sweeping robot.

Embodiment 3

[0030] Example 3: Such as Figure 4 , Figure 5 As shown, the cleaning head is an impeller structure, which is composed of a plate brush, including an upper cover 13 made of plastic, located below the upper cover, a plurality of circumferentially distributed cleaning blades 11 composed of bristles, and a central shaft of the upper cover The position is provided with a through hole 14 used as an installation location or a dust suction channel; in this embodiment, the rotation direction of the cleaning head is Figure 4 As shown by the middle arrow A, the cleaning blade 11 is bent toward the rotation direction of the cleaning head; the cleaning head in this embodiment can be used for a sweeper, a hand-push sweeper or a sweeping robot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com