A 4D printing system

A printing system and 4D technology, applied in the field of additive manufacturing, can solve problems such as low 4D printing efficiency, reduce wasted time, improve work efficiency, and prevent cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, further illustrate the present invention.

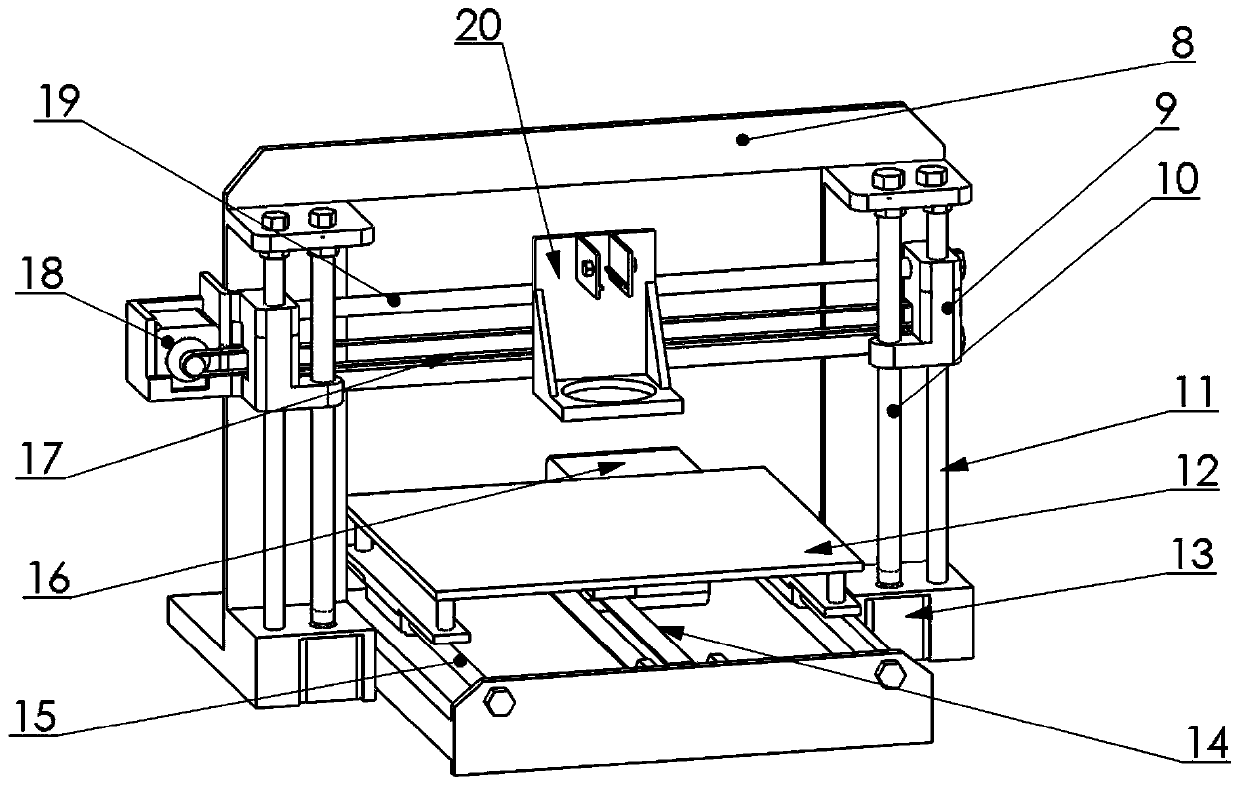

[0035] like image 3As shown, the motion device adopts the gantry structure, and this type of motion device can complete three-dimensional space motion with low precision requirements. Considering that the accuracy requirements of the printer are not very high, it is more economical to choose the gantry structure. The nozzle bracket 20 is installed on the X-direction movement component, and the nozzle bracket 20 moves along the X direction driven by the X-direction movement component. The X-direction movement component is connected with the Z-direction movement component. The platform 12 is connected with the Y-direction movement assembly, and the platform 12 moves along the Y-direction under the drive of the Y-direction movement assembly.

[0036] The Y direction movement assembly of the Y direction movement assembly includes a Y direction belt transmission mechanism and a Y gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com