Monitoring robot travelling mechanism for nano fiber production

A nanofiber and walking mechanism technology, applied in the direction of motor vehicles, transportation and packaging, can solve the problems of low security, easy to be blocked by obstacles, poor use effect, etc. Realize the effect of intelligent travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

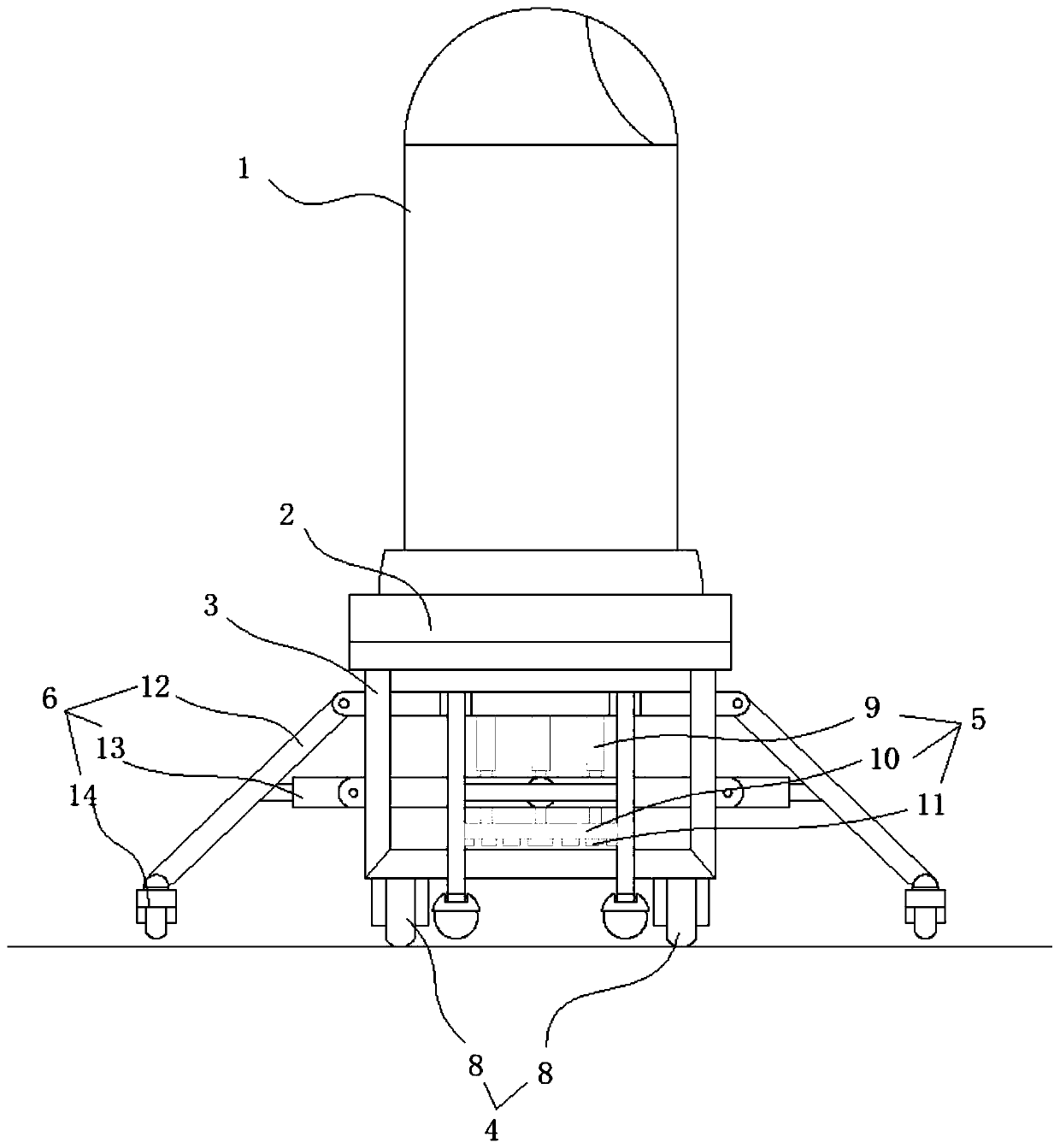

[0025] A monitoring robot walking mechanism for nanofiber production, installed on the chassis of the monitoring robot, characterized in that it includes a chassis bracket, and the chassis bracket is provided with a traveling mechanism, a steering mechanism, an obstacle-over-obstacle mechanism and an obstacle-over-obstacle controller ;

[0026] The traveling mechanism is composed of a plurality of first driving wheels, and the plurality of first driving wheels are distributed in the corners of the chassis bracket in a square shape;

[0027] The steering mechanism includes a first electric cylinder, a disc and a second driving wheel. The first electric cylinder is fixedly arranged in the chassis bracket, and its telescopic end is vertically downward, and is riveted and fixed with the disc. The disc Horizontally arranged, the second driving wheel is embedded on the disc and can rotate freely, and its lower end protrudes from the lower end surface of the disc. There are multiple ...

Embodiment 2

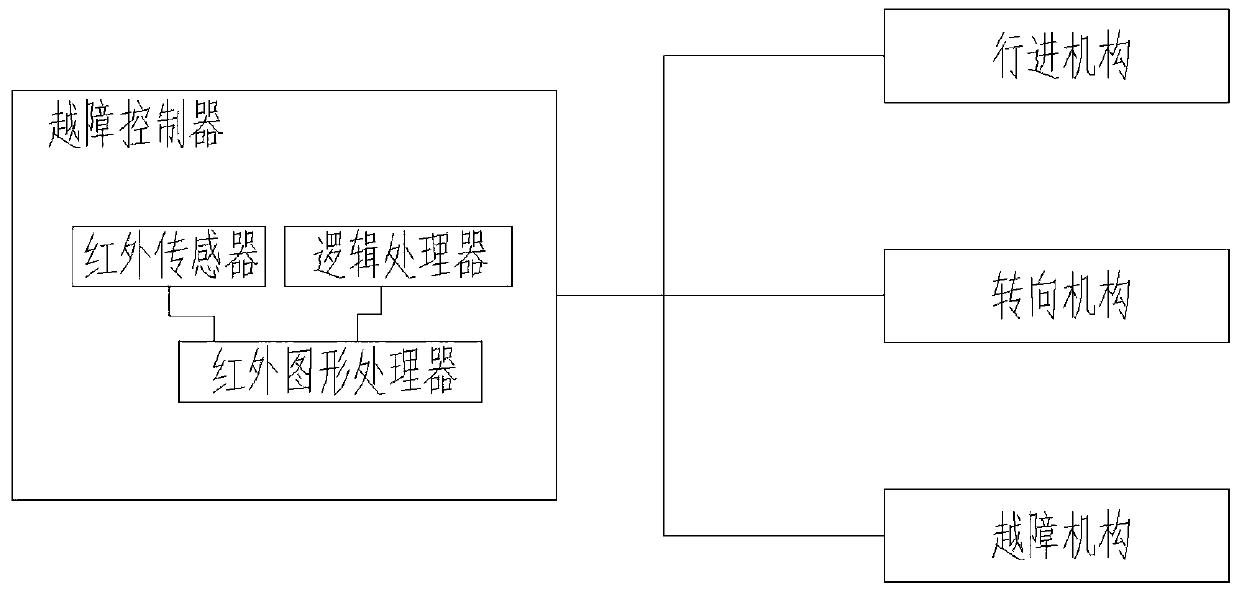

[0031] In this embodiment, the working principle and method of the obstacle-surmounting controller are described, as follows:

[0032] The obstacle clearance controller includes a logic processor, an infrared graphics processor and an infrared sensor, the infrared sensor interacts with the infrared graphics processor, the infrared graphics processor interacts with the logic processor, and the logic processor interacts with the traveling mechanism , the steering mechanism interacts with the obstacle overcoming mechanism to control the operation of the first drive wheel, the first electric cylinder, the second drive wheel, the second electric cylinder and the third drive wheel.

[0033] The infrared sensor senses the shape and size of the obstacle, and transmits the sensing data to the infrared graphics processor, and the infrared graphics processor performs shape processing, calculates the width d and height h of the obstacle, and transmits the data of the width d and height h o...

Embodiment 3

[0037] This embodiment describes the judgment method of the embodiment, specifically as follows:

[0038] When the width d and height h of the obstacle exceed the width data D1, the height data H2 from the ground, and the data of the change interval [(d1~dn):(h1~hn)], the logic processor controls the monitoring robot to perform obstacle avoidance steering. At the same time, the first electric cylinder is activated and extended to lower the disk and the second driving wheel until the first driving wheel is off the ground. Then, the second driving wheel is activated and the chassis support turns. When the steering is completed, the steering mechanism resets. When the first driving wheel touches the ground, the monitoring robot can avoid obstacles;

[0039]When the width d and height h of the obstacle are within the data range of the width data D1, the height data H2 from the ground, and the change interval [(d1~dn):(h1~hn)], the logic processor controls the monitoring robot to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com