Pull-out type goods shelf used for tool placement

A pull-out, racking technology, applied in the field of racks, can solve the problems of falling off, the hanging board cannot be pulled, and the pulling and hanging board is laborious, so as to prevent the unbalanced force, strengthen the detachability, and pull the hanging board. Effort-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

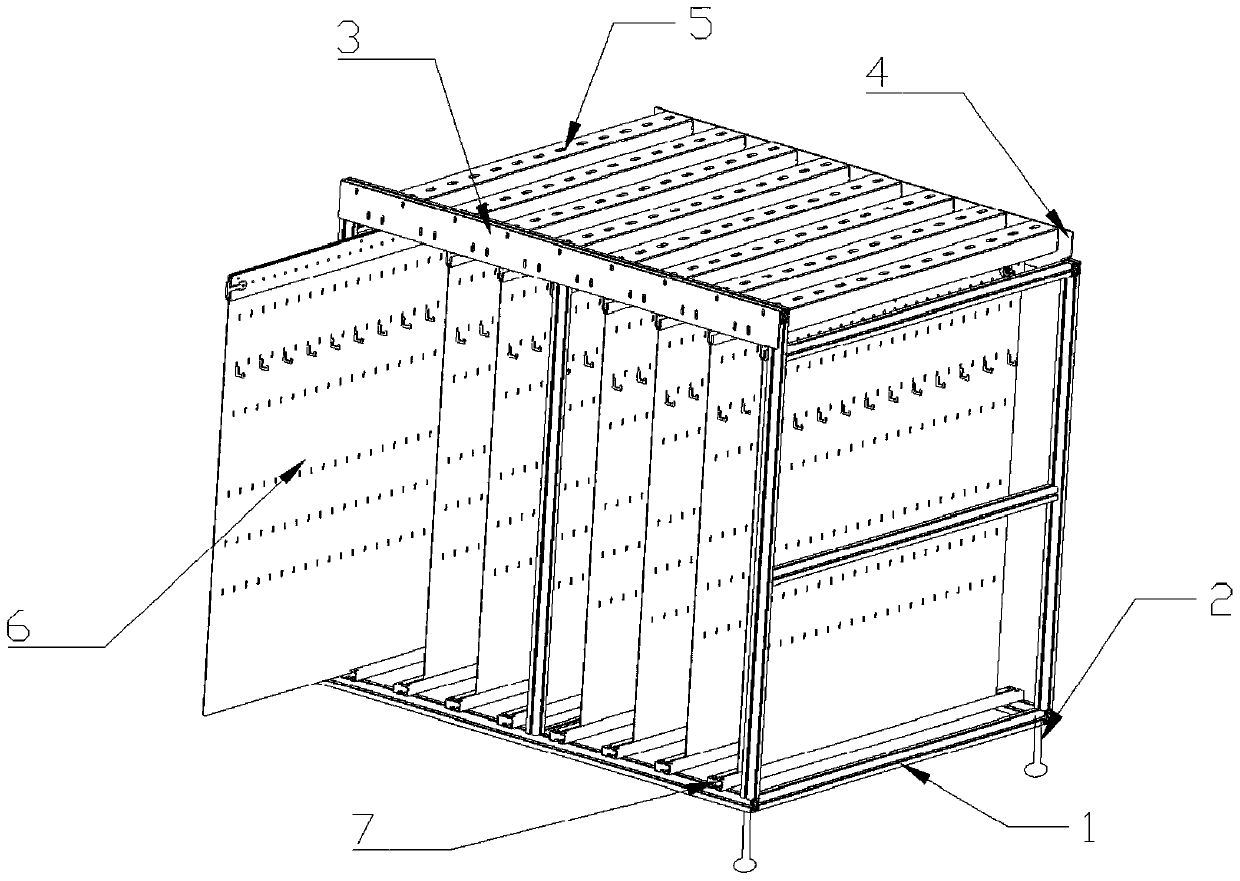

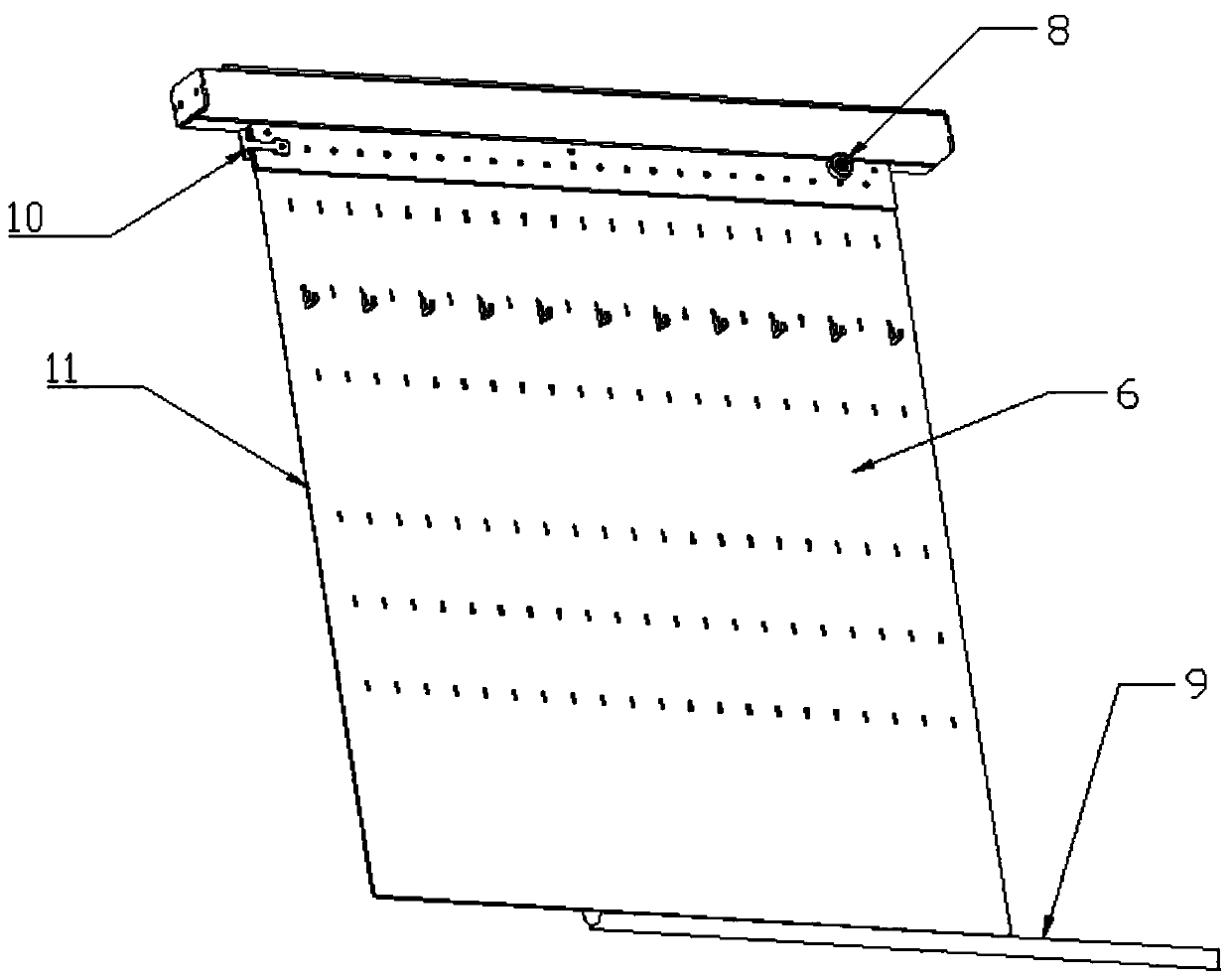

[0018] see Figure 1~2 , a pull-out shelf for tooling placement, including aluminum profile frame 1, support feet 2, front beam 3, rear beam 4, guide rail 5, hanging plate 6, limit bar 7, bearing group 8, hanging Plate limit groove 9, T-shaped handle 10 and anti-collision belt 11; the aluminum profile frame 1 adopts an aluminum profile with a selected cross-sectional size of 40mm*40mm, is located on the outermost side of the entire device, and constitutes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com