Preparation method of ester oil lithium grease

A lithium-based grease and ester oil technology, applied in the field of grease, can solve the problems of not fully containing ester oil, large loss of raw materials, long cycle, etc., and achieve the effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

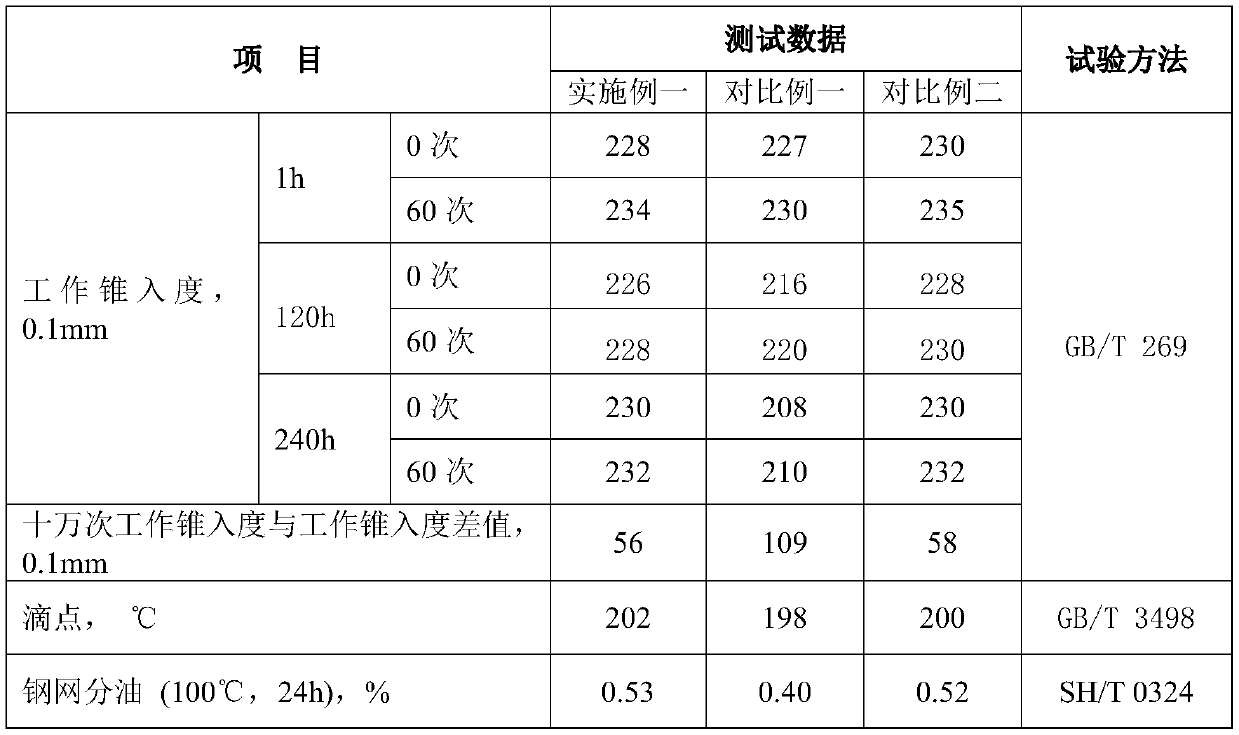

Examples

Embodiment 1

[0013] A preparation method of ester oil lithium base grease, comprising the steps of:

[0014] 1) Add 480g of ester oil and 120g of lauryl hydroxystearic acid in the reaction kettle, heat up and stir until the lauryl hydroxystearic acid is completely dissolved;

[0015] 2) Add 26.6g of oil-based anhydrous LiOH at 90°C;

[0016] 3) Heat up to 170-180°C, slowly add 200g of ester oil while stirring;

[0017] 4) Raise the temperature to 200-210°C, slowly add 200g of ester oil as quenching oil while stirring;

[0018] 5) Cool down to below 120°C, add antioxidant, extreme pressure anti-wear agent and anti-corrosion agent additives, and grind three times to obtain the finished lubricating grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com