Sewing machine for hemming

A sewing machine and hemming technology, which is applied to sewing machine components, needle holders for sewing machines, sewing equipment, etc., can solve the problems of affecting the appearance of finished products, high technical requirements, and difficulty in adjusting needle distances, so as to achieve accurate placement and ensure production. Efficiency and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

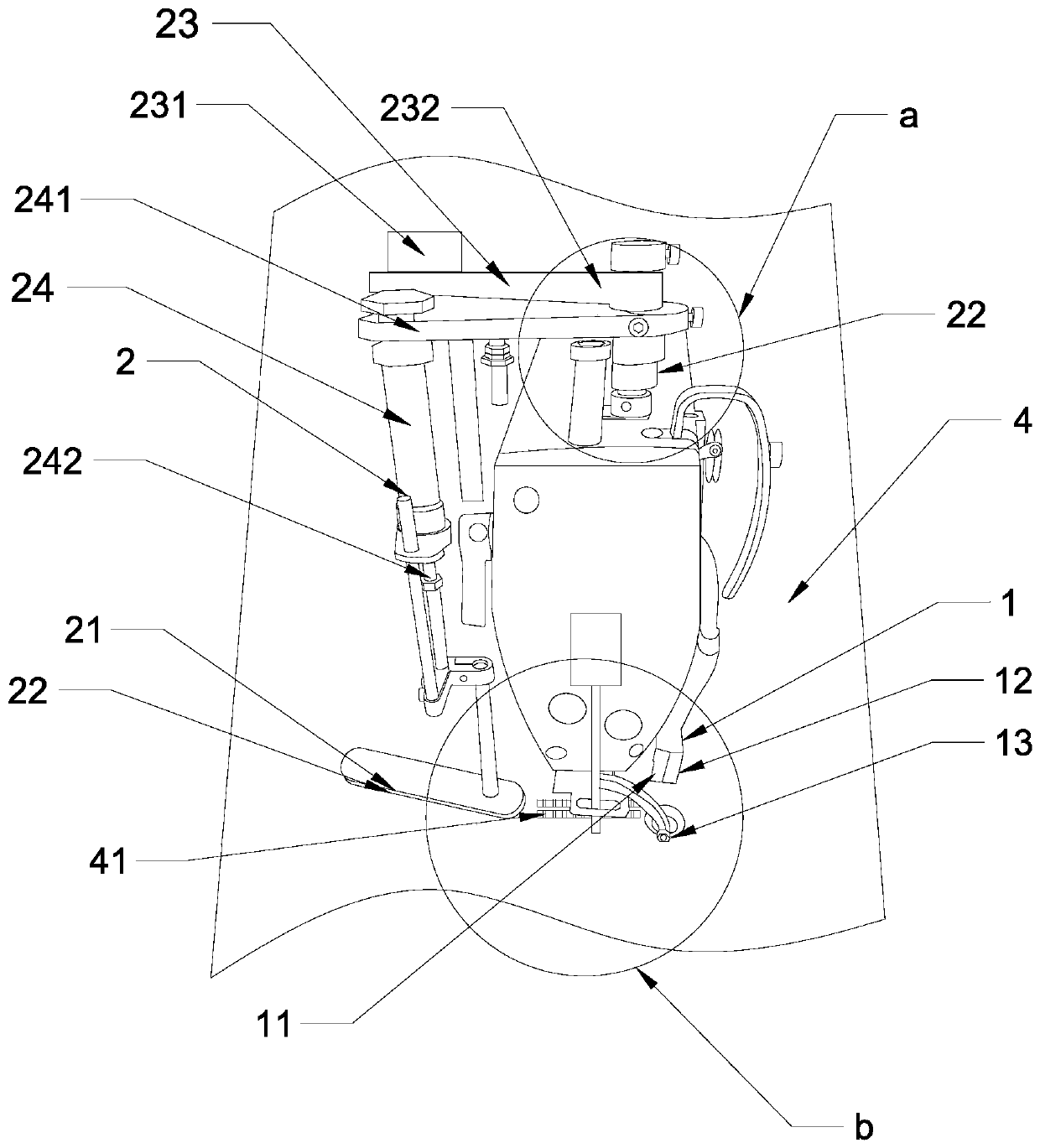

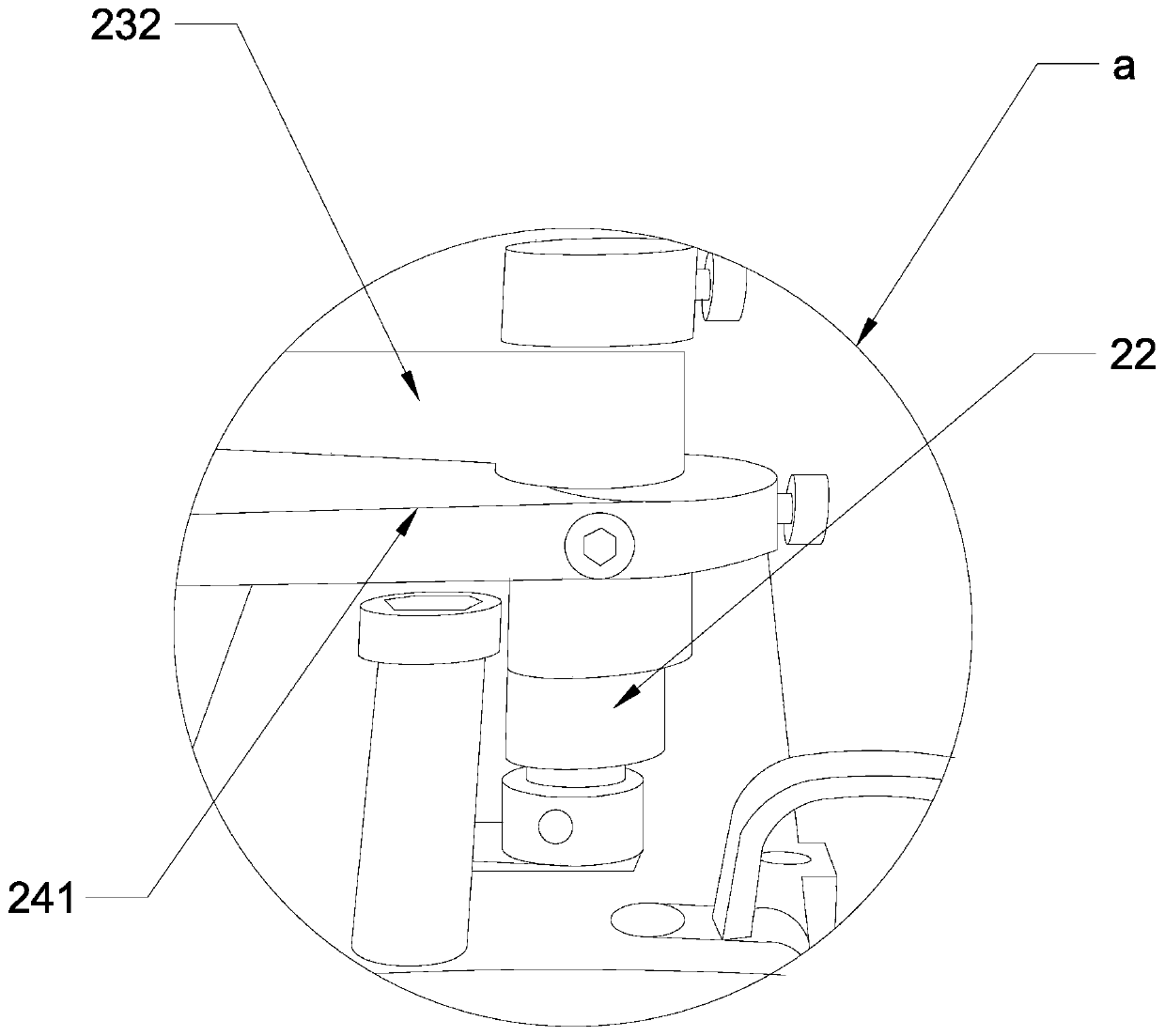

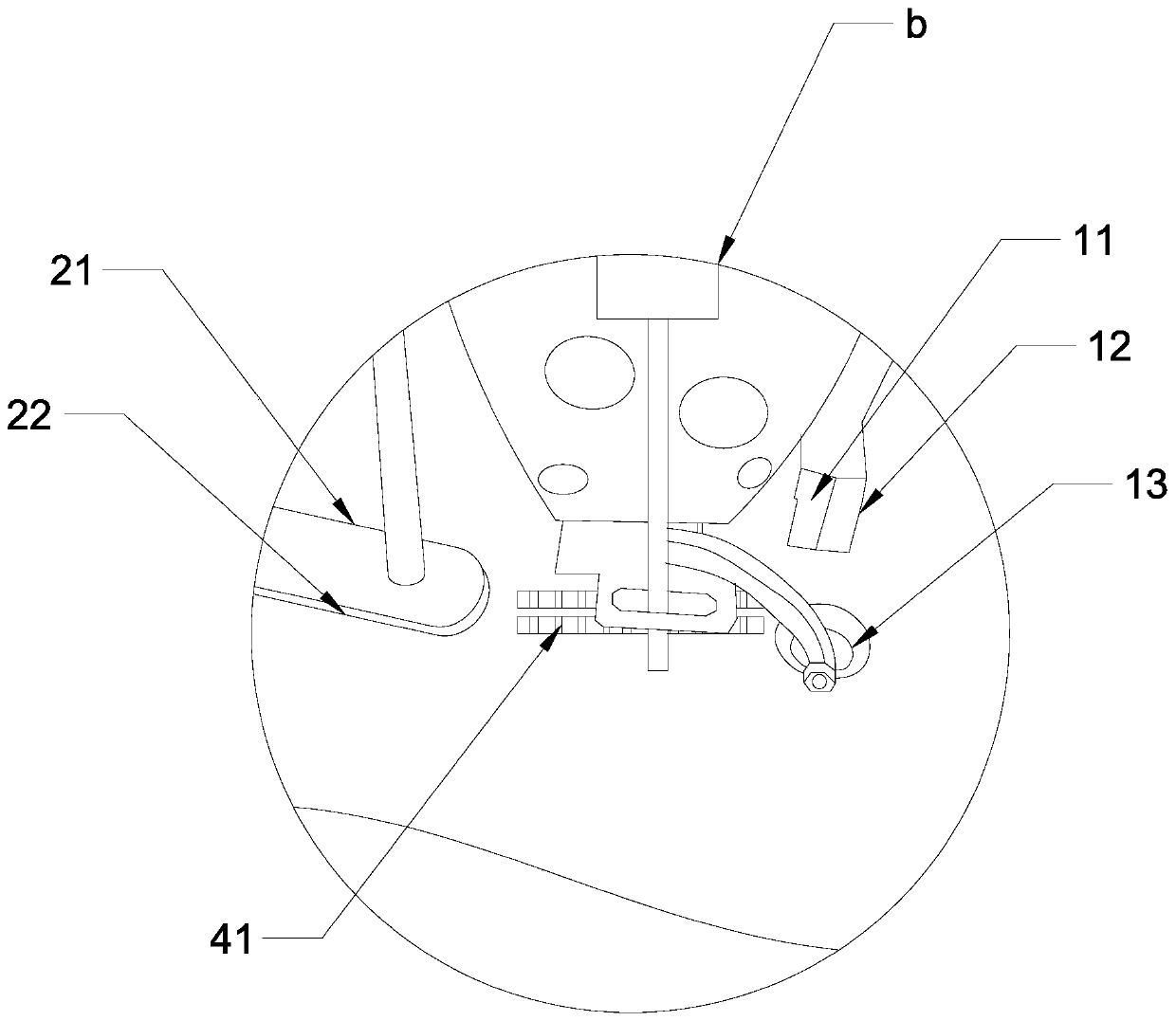

[0020] Embodiment of the sewing machine for hemming of the present invention Figure 1-4 As shown: it includes a distance measuring device 1, a mechanical arm 2, a stitch length adjusting device 3 and an operating table 4, and the operating table 4 is provided with feeding dogs 41 and sewing needles, and the distance measuring device 1 includes The first sensor 11 linked with the stitch length adjustment device 3, the first sensor 11 is arranged on the conveying path of the sewing material and can sense the edge of the sewing material, and the mechanical arm 2 is provided with a dragging piece 21. The dragging part 21 can be driven by the mechanical arm 2 to move along the console 4, the dragging part 21 can be telescopically arranged toward or away from the console, and the dragging part can be dragged in cooperation with the console 4 sewing material. The stitch length adjustment device 3 includes an adjustment member 32 driven by a motor 31 and a stitch length seat 33 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com