a printing method

A technology of dyes and dye vats, which is applied in the field of printing and dyeing cloth preparation, can solve problems such as limitations of artistic features, time-consuming production process, and complicated engraving process, and achieve the effects of increasing artistic value, good reproducibility, and improving richness and artistic features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the printing and dyeing method steps are as follows:

[0040] (1) Wash the cotton cloth with warm water to remove the starch, dry it and iron it to make it smooth;

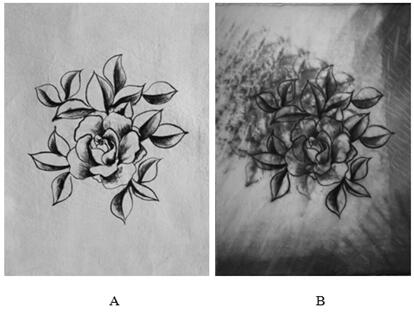

[0041](2) Use hot water to prepare reactive dyes (dark blue direct dyes, Tianjin Fangyang brand), draw the outline of the pattern on the flat fabric with a hook pen, and after the drawn pattern is basically dry, use a pen to align the reactive dye with the pattern Rendering (mainly when rendering, use a pen to dip a certain amount of reactive dye and apply it to the pattern, and then use a pen with clear water to smudge the part where the paint has just been applied. This painting method is similar to the technique of Chinese meticulous painting). After the drawing is completed, After the pattern is completely dry, iron the fabric flat from the back of the pattern;

[0042] (3) Wrap the patterned fabric from the back of the screen, roll it from the corner of the fabric, roll it tightly into a...

Embodiment 2

[0043] Embodiment 2: the printing and dyeing method steps are as follows:

[0044] (1) Wash the cotton cloth in cold water to remove the starch, dry it and iron it to make it smooth;

[0045] (2) Use reactive dye (peach red direct dye) to draw half of the symmetrical pattern on the flat cloth. After the pattern is completely dry, iron the cloth from the back of the pattern;

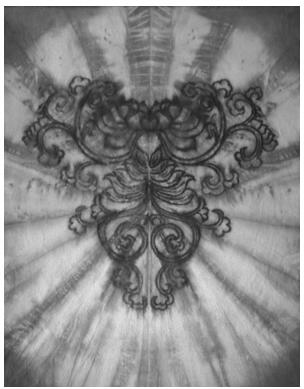

[0046] (3) Fold the patterned fabric (fold in half along the edge of the drawn pattern, then cross-fold) in half, and then fold the folded fabric into a triangular piece (fold a right angle on the folded fabric, and then fold it in half repeatedly , so that the pattern is located at the sharp corner of the triangular block), so that the pattern is located at the sharp corner of the triangular block, tie it up equidistantly with thread, put it in boiling water for 7 minutes, take out the dyed fabric, remove the stitches, and wash with soap Once, rinse with clean water, dry, and iron to complete the printi...

Embodiment 3

[0047] Embodiment 3: the printing and dyeing method steps are as follows:

[0048] (1) Wash the linen cloth in cold water to remove the starch, dry it and iron it to make it smooth;

[0049] (2) Use reactive dye (sky blue direct dye) to draw a pattern on the flat fabric, and iron the fabric from the back of the pattern after the pattern is completely dry;

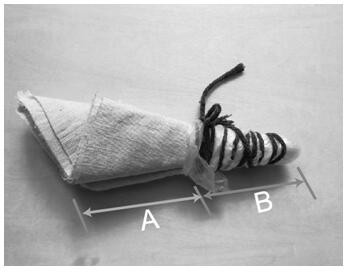

[0050] (3) Fold the fabric with the pattern in half into a triangular block (first fold the fabric in half in different directions twice, make a right angle on the folded fabric, and then fold it in half repeatedly), so that the pattern is located at the sharp corner of the triangular block, use a thread Part of the isometric tie pattern ( image 3 , Section B is the patterned part), put the patterned part into boiling water for boiling and dyeing, take it out, wrap the patterned part tightly with a plastic bag, and then put the non-patterned part ( image 3 Section A) put into the dyeing vat with dye for cooking and dyei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com