Scaffold supporting structure and system

A technology for supporting structure and supporting system, which is applied in the direction of housing structure support, housing structure support, scaffolding accessories, etc. It can solve the problems of limited application scope, unclear force on the structural system, hidden dangers of safety and quality, etc., and achieve fast installation and disassembly. Simple, saves the overall erection time, and has the effect of reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

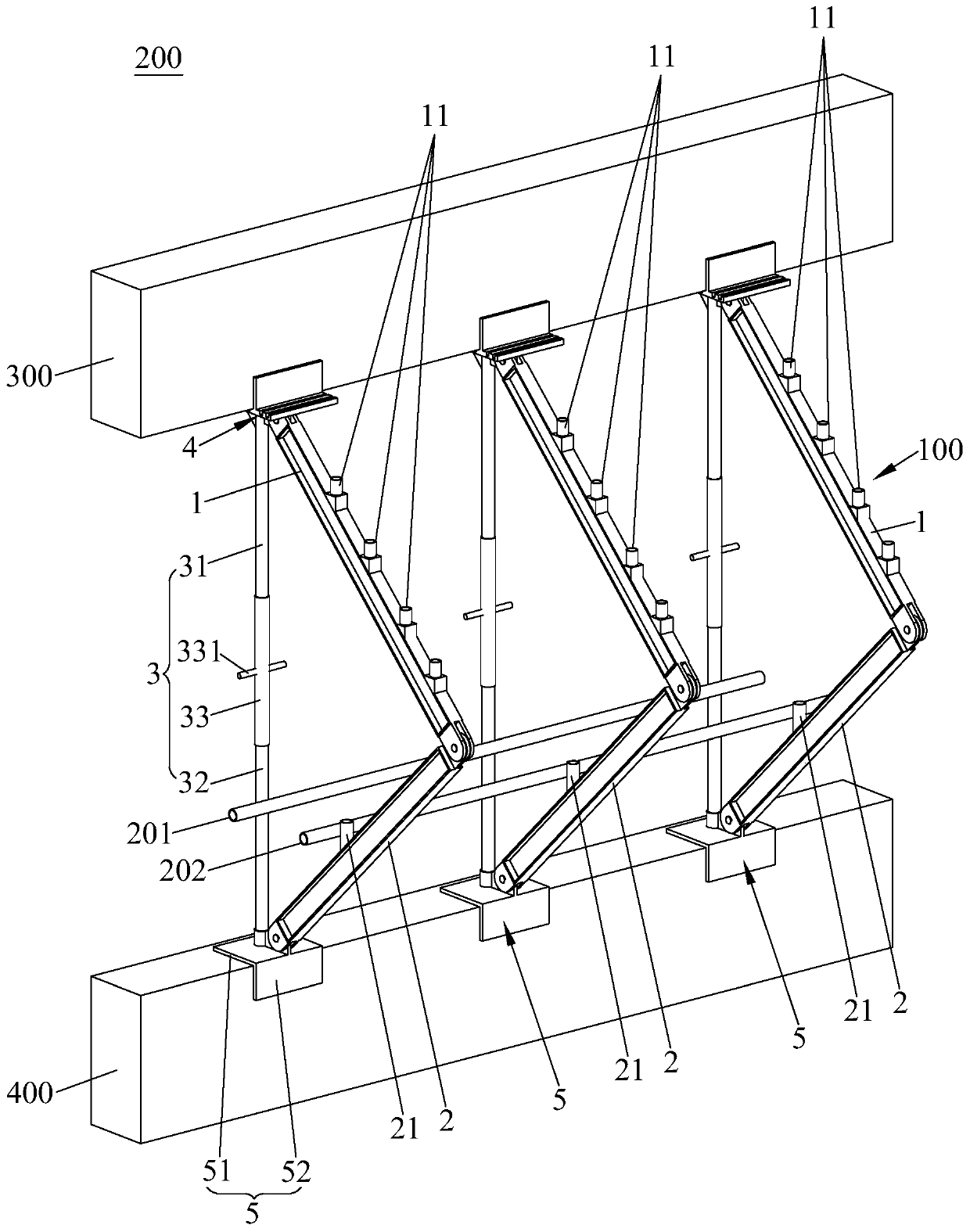

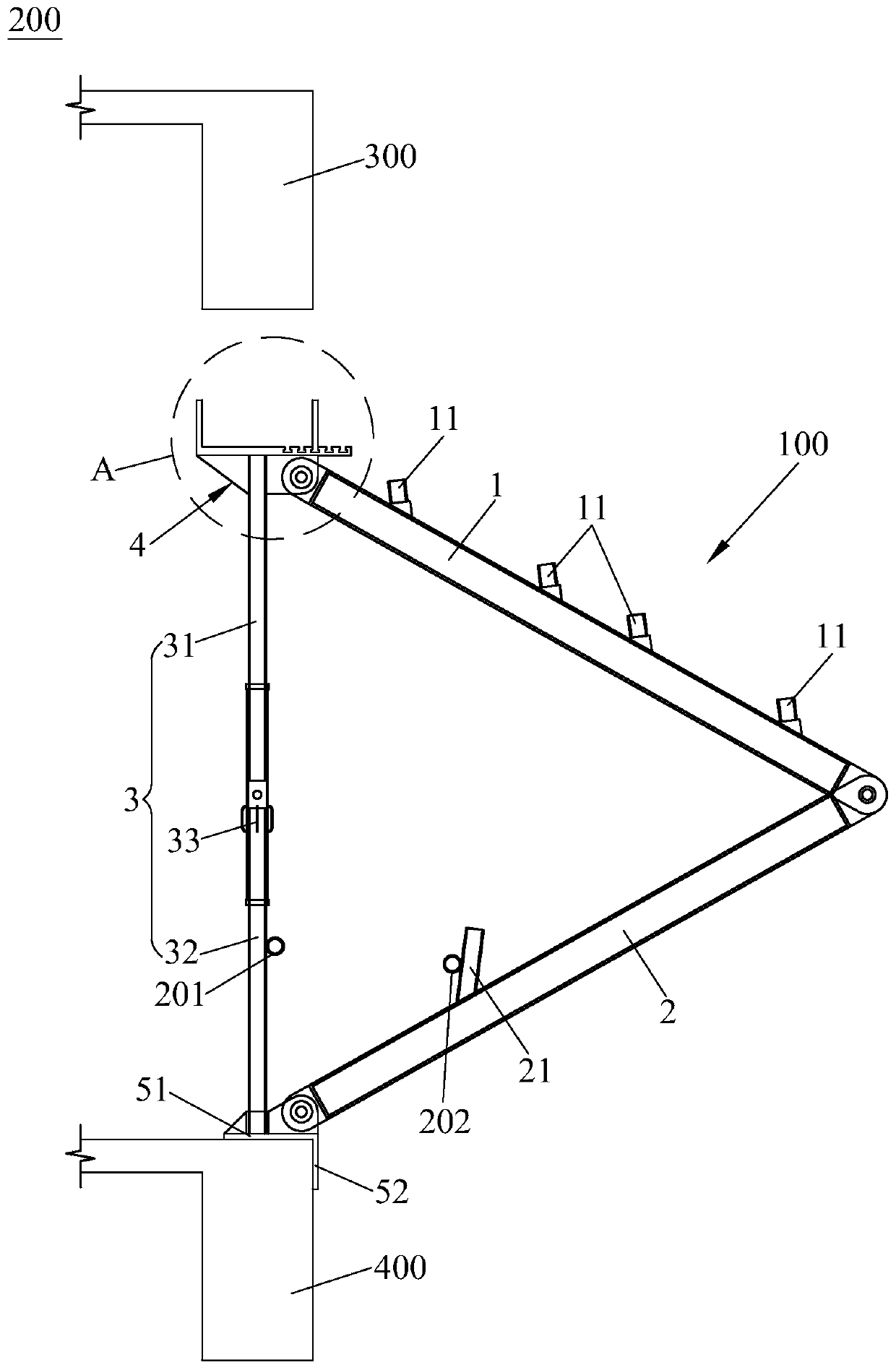

[0027] combine figure 2 and Figure 4 , taking the three scaffolding support structure 100 as an example, the specific implementation of the scaffolding support system 200 of the present invention is as follows:

[0028] S1, process and manufacture all parts of the present invention, weld the support 11 at the preset position of the first diagonal support 1, weld the auxiliary rod at the preset position of the second diagonal support 2, and transport the manufactured parts to Construction and installation floors;

[0029] S2, place the components on a simple flatbed truck for plane installation, forming a figure 1 For the scaffold support structure 100 shown, the simple flatbed truck is moved to the installation position, the scaffold support structure 100 is suspended by a tower crane, and the second engaging part 5 is engaged on the lower side beam 400;

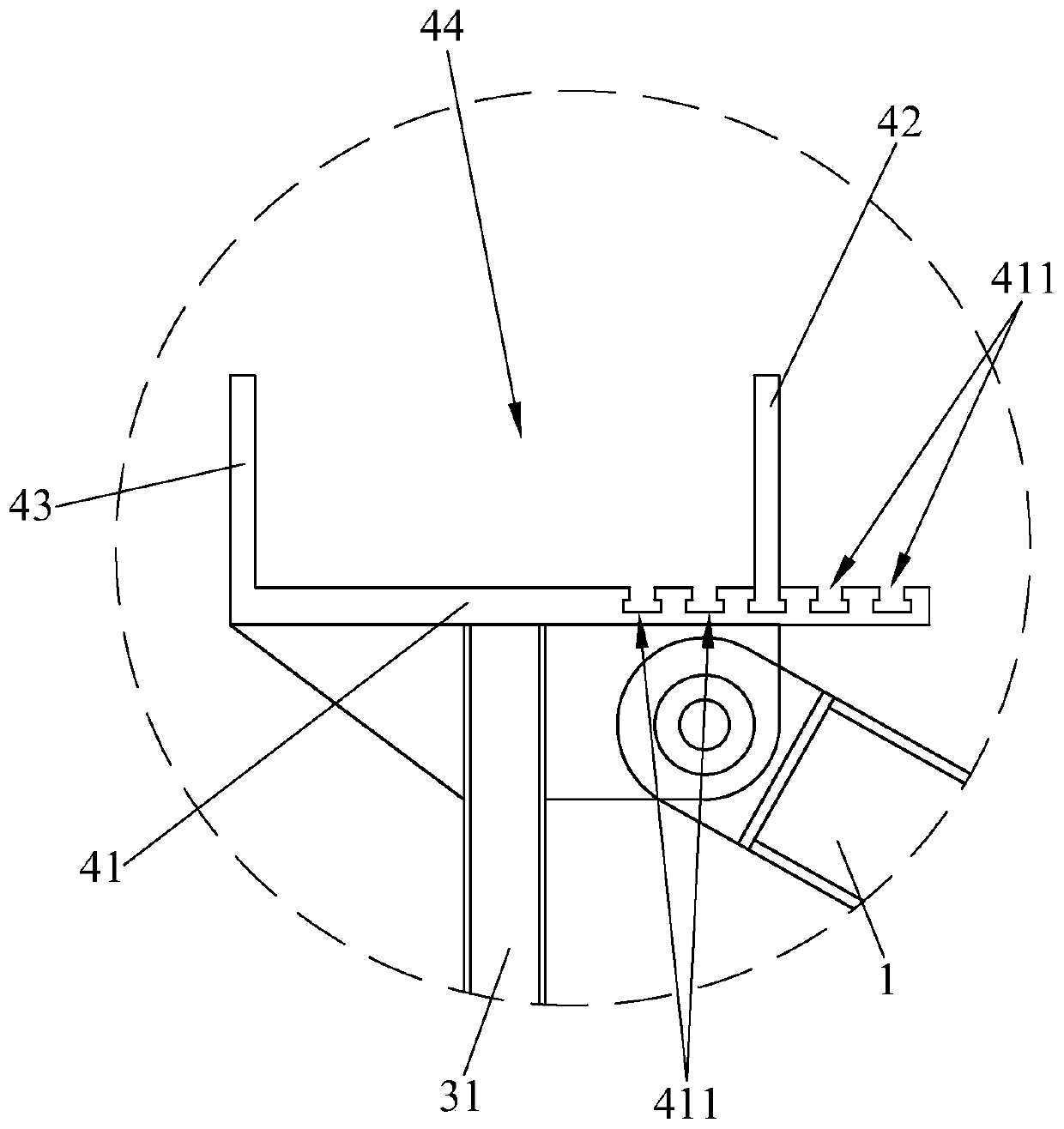

[0030] S3, adjust the first side plate 42 into a suitable adjustment groove 411 according to the beam width of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com