Design method of irregular air film cooling hole

A film cooling and design method technology, which is applied in mechanical equipment, blade support elements, engine elements, etc., can solve the problems of insufficient research on the mutual influence mechanism and complicated influence, and achieves a simple and easy-to-implement design method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] This embodiment is a design method of a special-shaped film cooling hole.

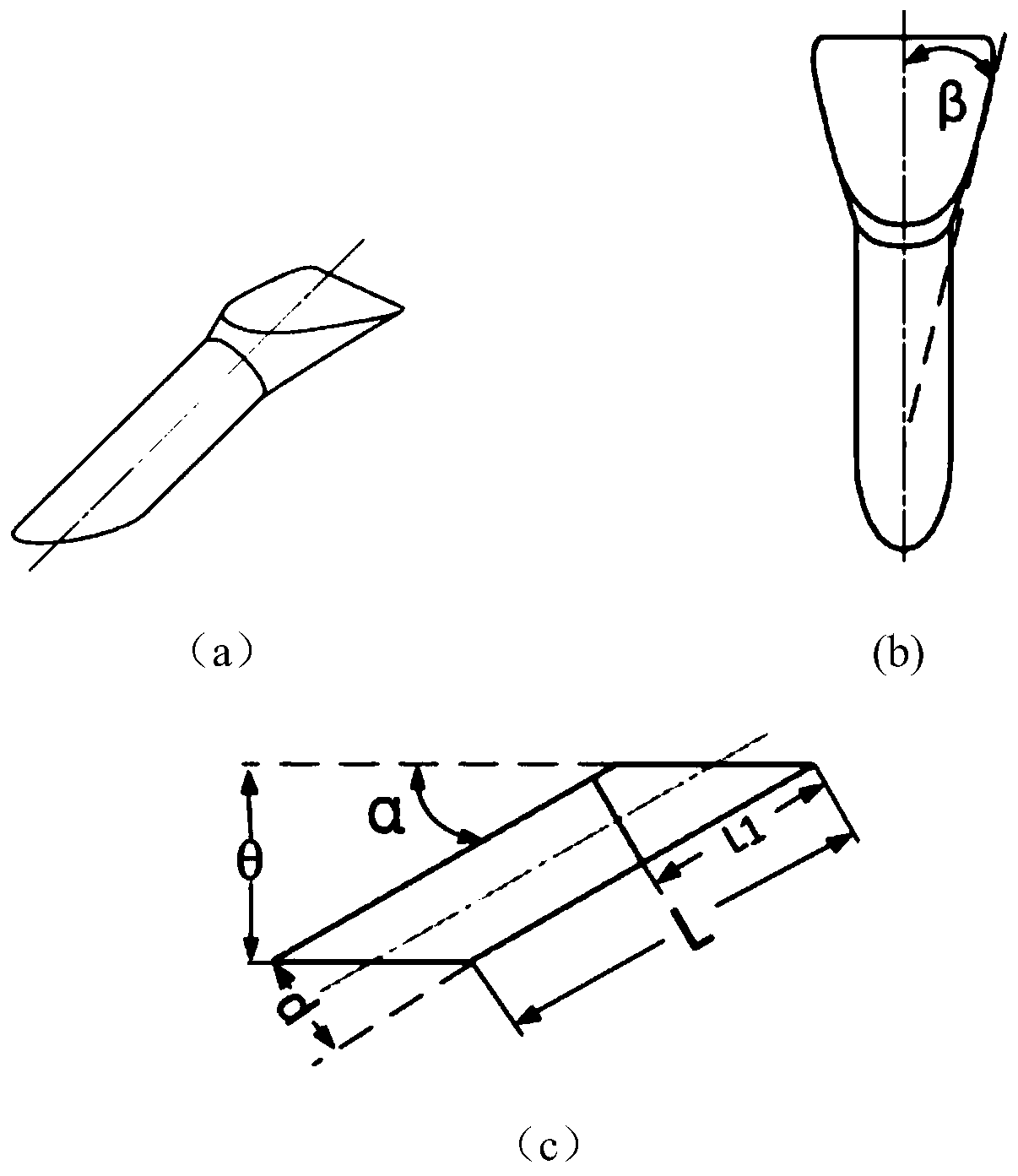

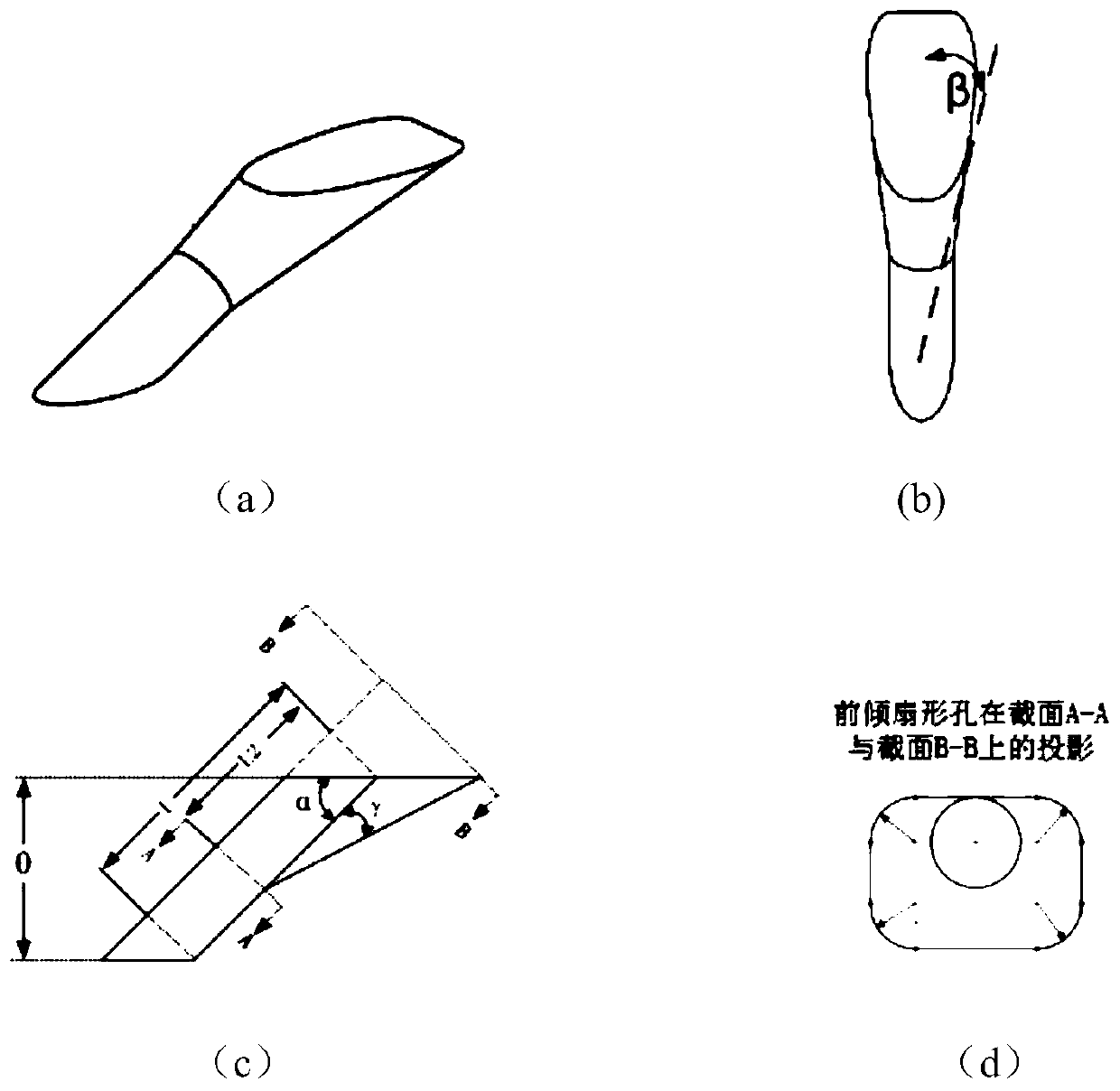

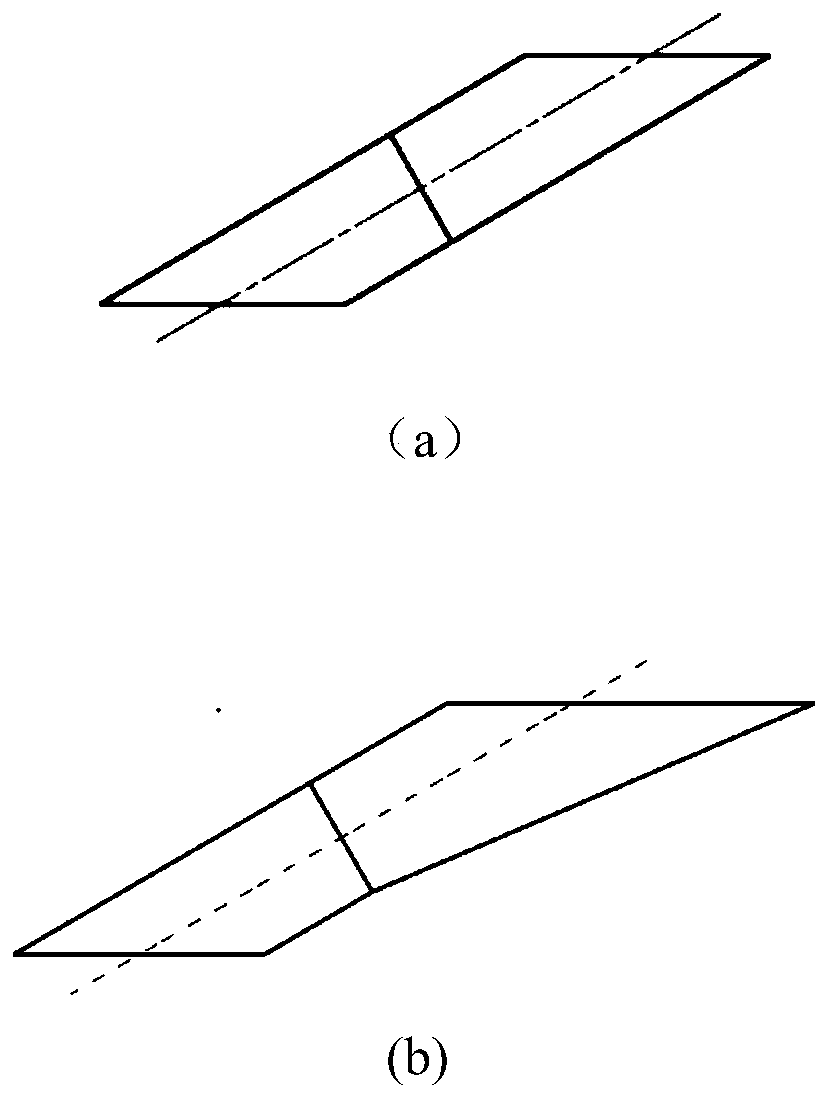

[0035] refer to figure 1 (a), (b), (c)~ Figure 4 (a), (b), in the design method of special-shaped film cooling holes in this embodiment, two representative special-shaped holes are selected, one is a fan-shaped hole, which only has a spanwise expansion angle; the other is a forward tilt The fan-shaped hole expands to the flow direction on the basis of the fan-shaped hole, and not only has a span-wise expansion angle but also a flow-direction expansion angle. The extension depth of both hole types is 3 / 4 of the hole length.

[0036] In this embodiment, the film cooling characteristics of special-shaped holes under two different film hole jet angles of 30° and 45° are studied and analyzed.

[0037] For common fan-shaped holes and forward-inclined fan-shaped holes, numerical simulations are carried out under different jet angles and divergence angles, and different modeling parameters are compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com