Loosing-prevention bolt component with disassembling being controlled by preset torque

An anti-loosening bolt, preset torque technology, applied in the direction of bolts, threaded fasteners, connectors with special improvement in tensile load, etc. and other problems, to achieve the effect of good sealing, high safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

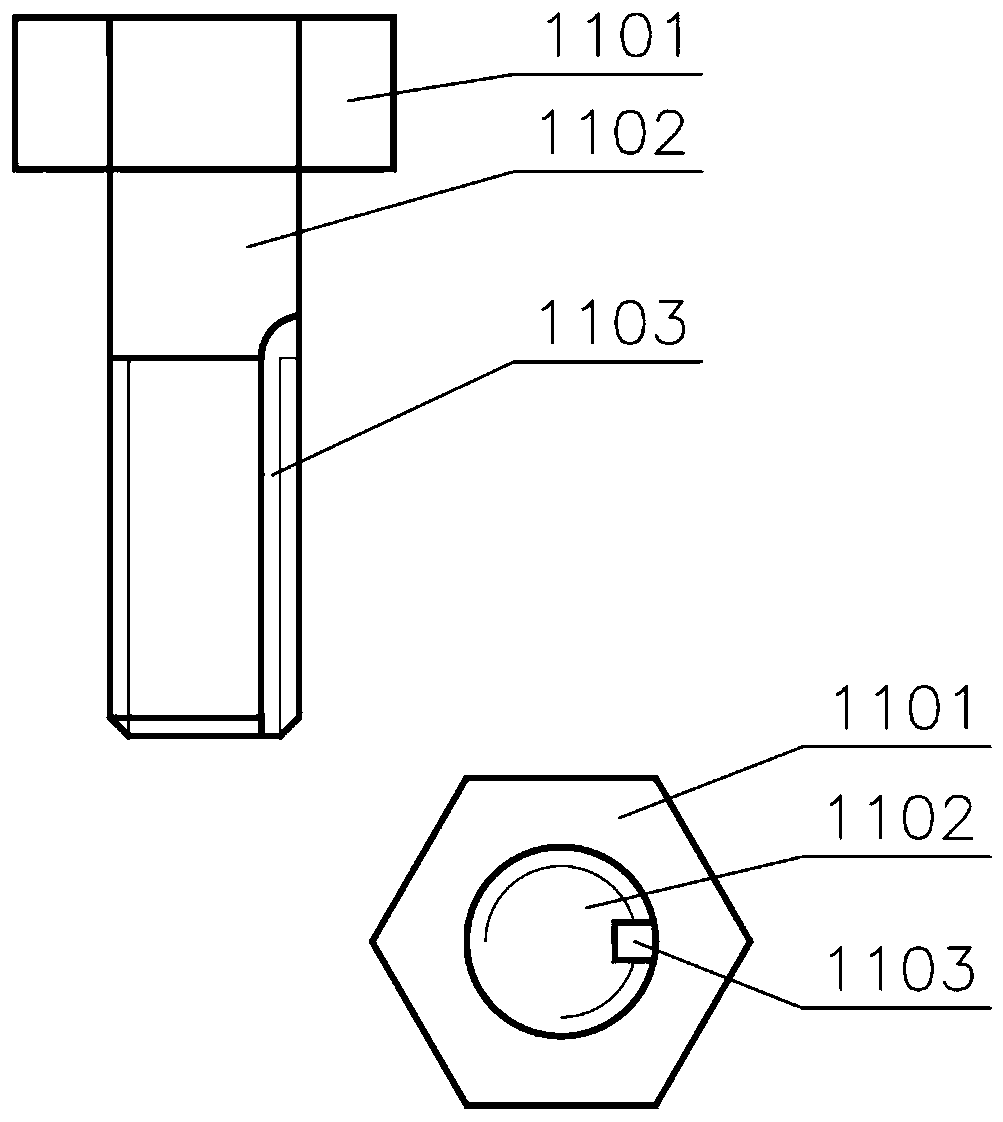

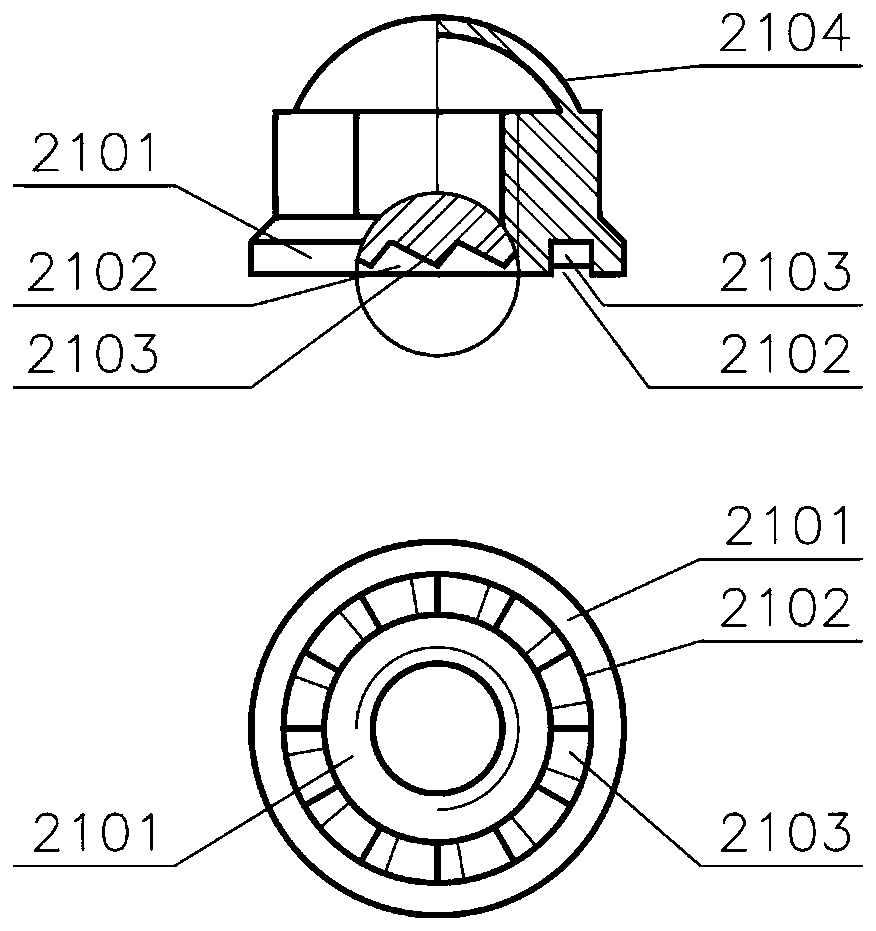

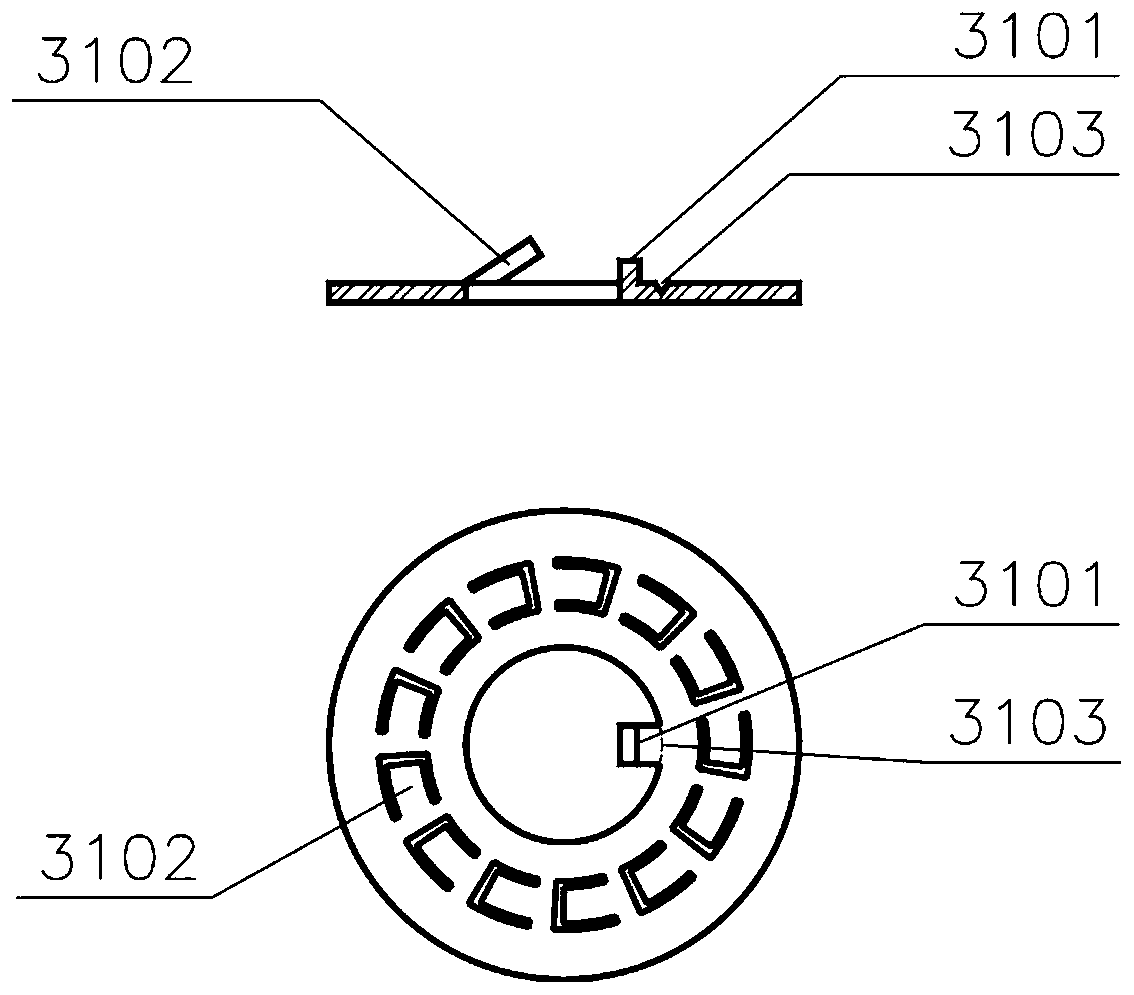

[0052] Such as figure 1 , figure 2 , image 3 and Figure 7 As shown, an anti-loosening bolt assembly with preset torque control disassembly includes a bolt 11 , a nut 21 , and a stop washer 31 that cooperate with each other. The bolt 11 includes a nut 1101 and a screw rod 1102. The screw rod 1102 is provided with an axial groove 1103 along the axial direction; The nut 21 is provided with a radial annular flange 2101 at one end close to the fastened part; the outer diameter of the annular flange 2101 is greater than the outer diameter of the nut 21; an annular groove 2102 is provided at the annular intermediate position of the end surface where the annular flange 2101 is located ; The bottom surface of the annular groove 2102 is provided with ratchet structures 2103 arranged radially and evenly. The stop washer 31 is annular, and the outer diameter of the stop washer 31 is greater than the outer diameter of the annular flange 2101; the inner hole of the stop washer 31 is ...

Embodiment 2

[0054] Such as Figure 4 , Figure 5 and Figure 8As shown, a anti-loosening bolt assembly with preset torque control dismounting includes a bolt 12 , a nut 22 , and a stop washer 32 that cooperate with each other. The nut 1201 of the bolt 12 is provided with a radial annular flange 1202 near one end of the fastened part 41; the outer diameter of the annular flange 1202 is greater than the outer diameter of the nut 1201; the annular flange 1202 is provided with a The annular groove 1203 and the ratchet structure 1204 are the same as the annular groove 2102 and the ratchet structure 2103 in Embodiment 1; the screw rod of the bolt 12 is not provided with an axial groove. The nut 22 is an ordinary nut matched with the bolt 12 . The stop washer 32 is annular, and the outer diameter of the stop washer 32 is greater than the outer diameter of the annular flange 1202; the stop washer 32 is basically the same as the stop washer 31 in Embodiment 1, and the difference is that the sto...

Embodiment 3

[0056] Such as Figure 4 , Image 6 and Figure 9 As shown, a anti-loosening bolt assembly with preset torque control disassembly includes a bolt 12 , a nut 22 , and a stop washer 33 that cooperate with each other. This embodiment is basically the same as Embodiment 2, except that the stop washer 33 of this embodiment replaces the stop washer 32 of Embodiment 2. The stop washer 33 is also basically the same as the stop washer 32, the difference is: the stop washer 33 is not provided with a rectangular gap, instead the rectangular orifice 3301 is placed in the middle of the ring body from the stop washer 33 inner hole; The lateral inner edge of the opening 3301 is provided with a vertical protrusion 3302 that is bent towards the fastener 43; the top of the vertical protrusion 3302 is set as a tip 3303, and the tip 3303 is located at the center point of the section of the vertical protrusion 3302; the vertical protrusion 3302 A prefabricated notch 3304 is provided at the join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com