Transmission rod for Hopkinson compression rod experiment and Hopkinson compression rod experimental device

A technology of Hopkinson compression rod and experimental device, which is applied in the direction of measuring device, using repeated force/pulsation force to test the strength of materials, instruments, etc., which can solve problems such as delay, elimination of reflected pulse, and larger size of transmission rod device. Achieve the effects of protection device, easy transportation and use, and short length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

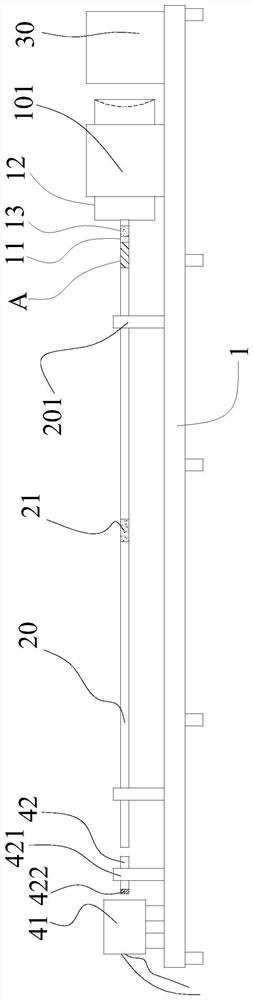

[0028] Now illustrate the embodiment of this experimental device in conjunction with accompanying drawing.

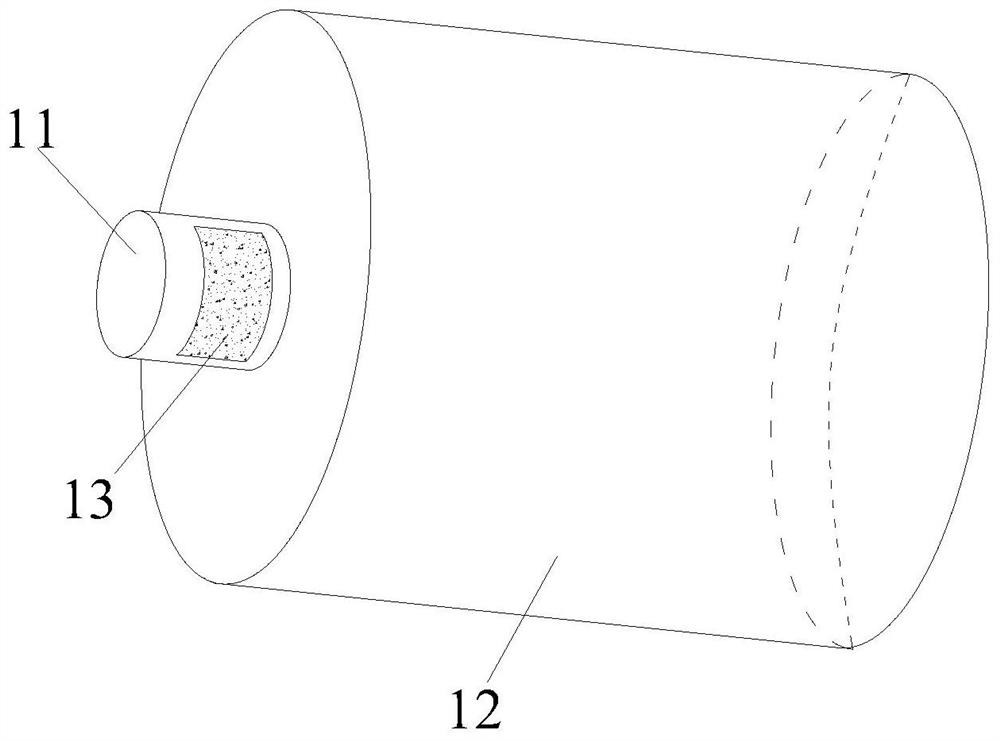

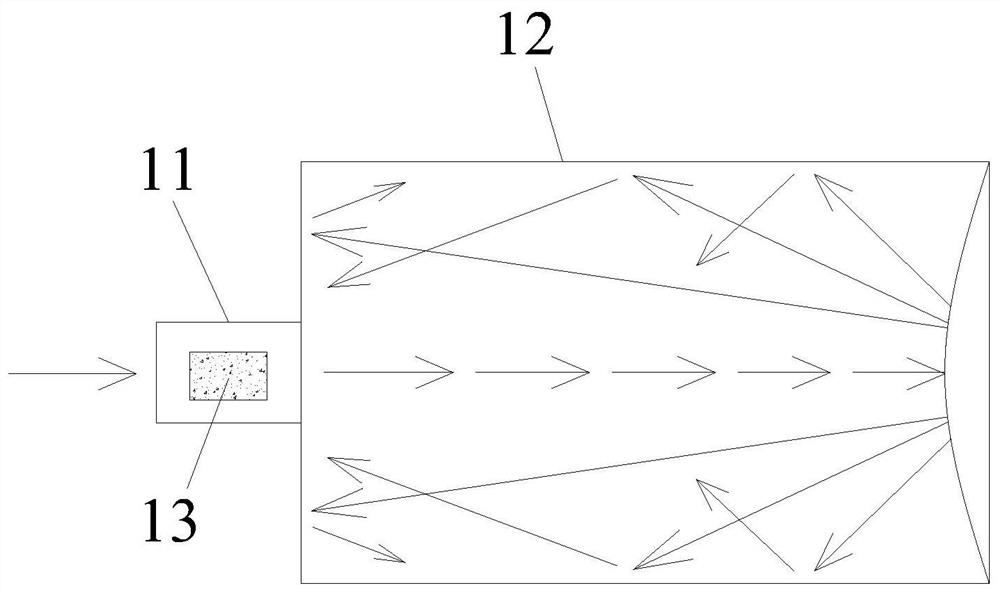

[0029] Such as figure 1 As shown, a transmission rod for Hopkinson compression bar experiment is provided with a transmission rod strain gauge 13. It is characterized in that the transmission rod is composed of a front cylinder 11 and a rear cylinder 12, and the front cylinder 11 and the rear cylinder 12 are integrally formed coaxial cylinders; the diameter of the front cylinder 11 is smaller than the diameter of the rear cylinder 12, and the through-rod strain gauge 13 is arranged on the front cylinder 11.

[0030] The free end surface of the cylinder 12 in the rear area is a concave curved surface.

[0031] The free end surface of the cylinder 12 in the rear area is an arc surface concave toward the center.

[0032] The front cylinder 11 has a diameter of 14 mm and an axial length of 13 mm; the rear cylinder 12 has a diameter of 100 mm and an axial length of 200 mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com