Electric quantity consumption analysis method and system

A technology of electricity consumption and analysis method, which is applied in the field of cold rolling, can solve problems such as complex process conditions, high production costs of enterprises, and unrefinement, and achieve the effects of cost reduction, energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiment of the present invention realizes the technical effect of refined analysis of power consumption by providing a power consumption analysis method and system.

[0042] The general idea of the technical solution in the embodiment of the present invention is as follows:

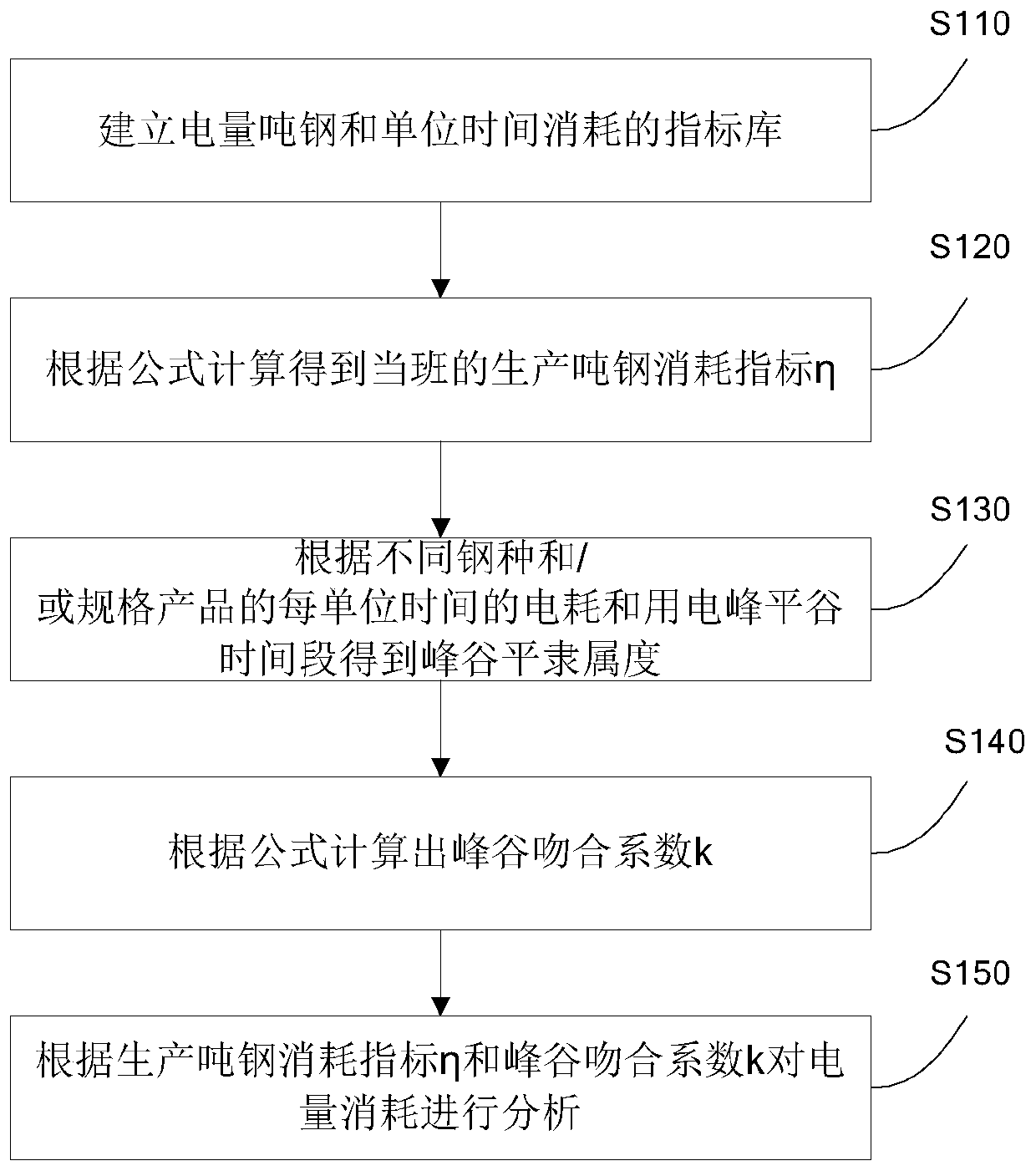

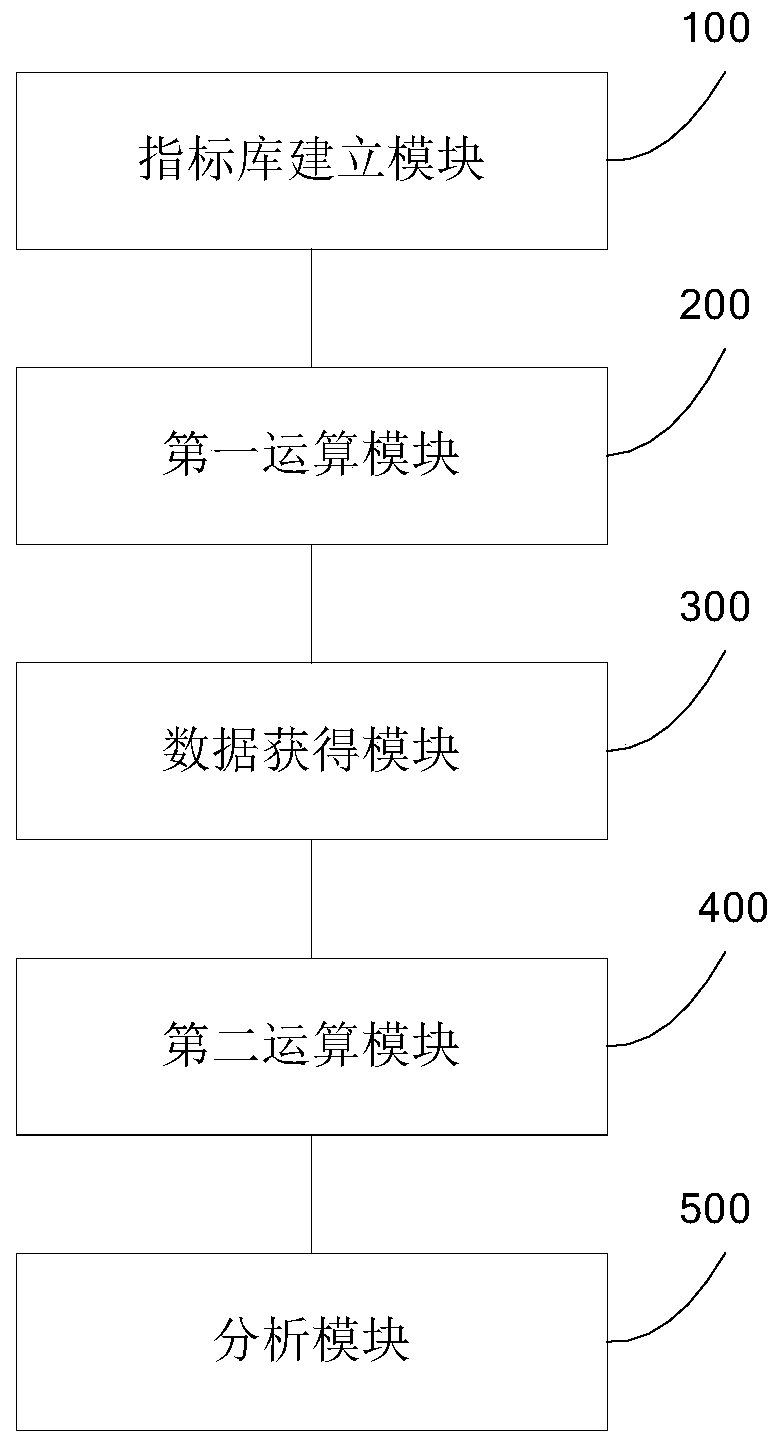

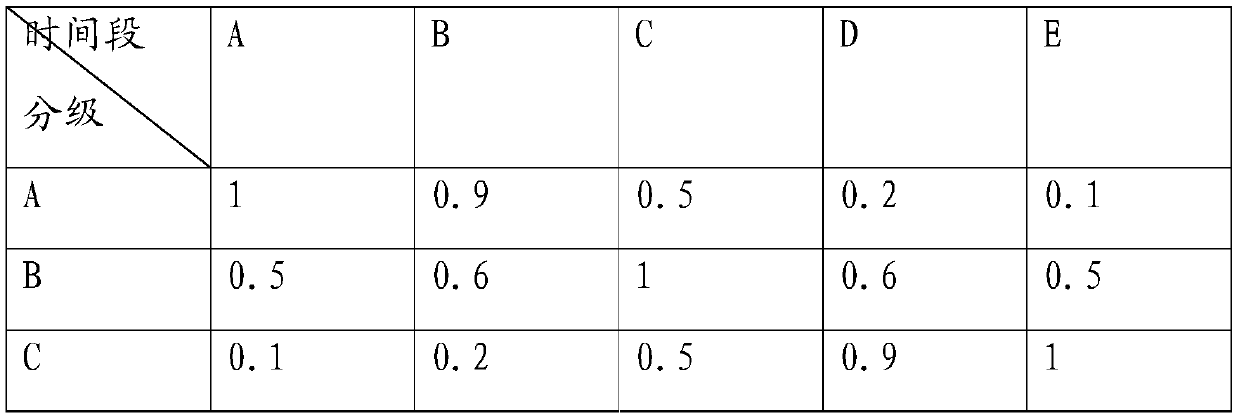

[0043] Firstly establish the index library of electricity ton steel and unit time consumption; then calculate the production ton steel consumption index of the shift; then obtain the peak value according to the power consumption per unit time of different steel types and / or specifications products and the peak and valley time periods of power consumption. Valley-level membership degree; then calculate the peak-valley coincidence coefficient; finally analyze the power consumption according to the consumption index per ton of steel produced and the peak-valley coincidence coefficient, and realize the refined analysis of the power consumption of cold-rolled steel grades and specifications. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com