New energy automobile capacitor embedding tool

A technology for new energy vehicles and capacitors, which is applied to the packaging of capacitor devices, capacitors, and capacitor manufacturing. It can solve the problems of easy electrode offset, poor appearance and size, and heavy iron tooling, so as to improve potting efficiency and assembly. Convenience, the effect of ensuring the quality of potting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0023] Aspects of the invention are described in accordance with figure 1 in the orientation shown, i.e. figure 1 The up, down, left, and right directions shown are the described up, down, left, and right directions. figure 1 The side facing is the front, and the side facing away from figure 1 One side is the rear.

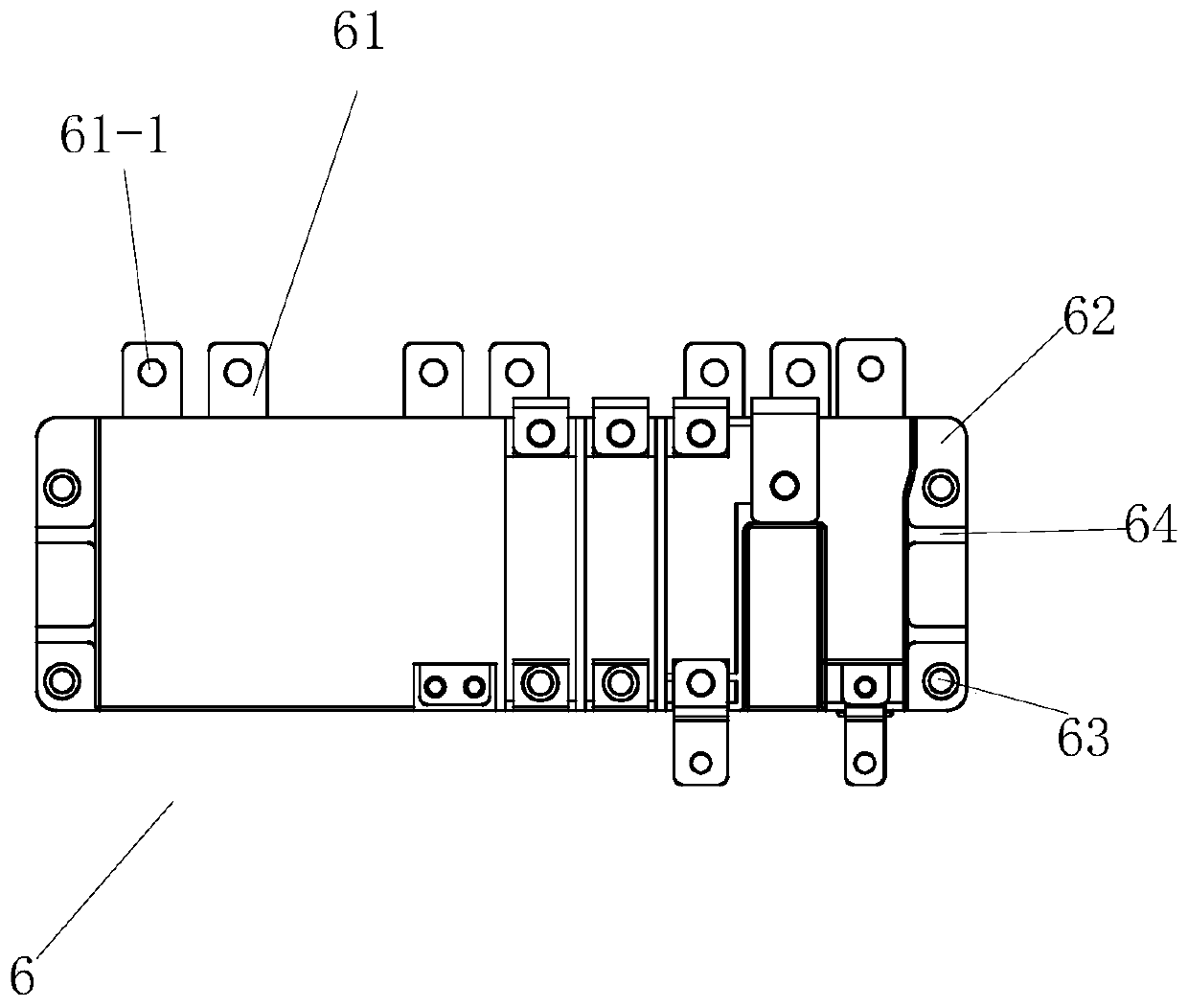

[0024] See image 3 , the shell main body of the capacitor 6 to be potted is substantially cuboid, and the left and right sides are provided with mounting base 62, and mounting hole 63 is provided on the mounting base 62; The electrode sheet 61 is arranged above and below the shell body, and a connection hole 61 - 1 is opened on the electrode sheet 61 .

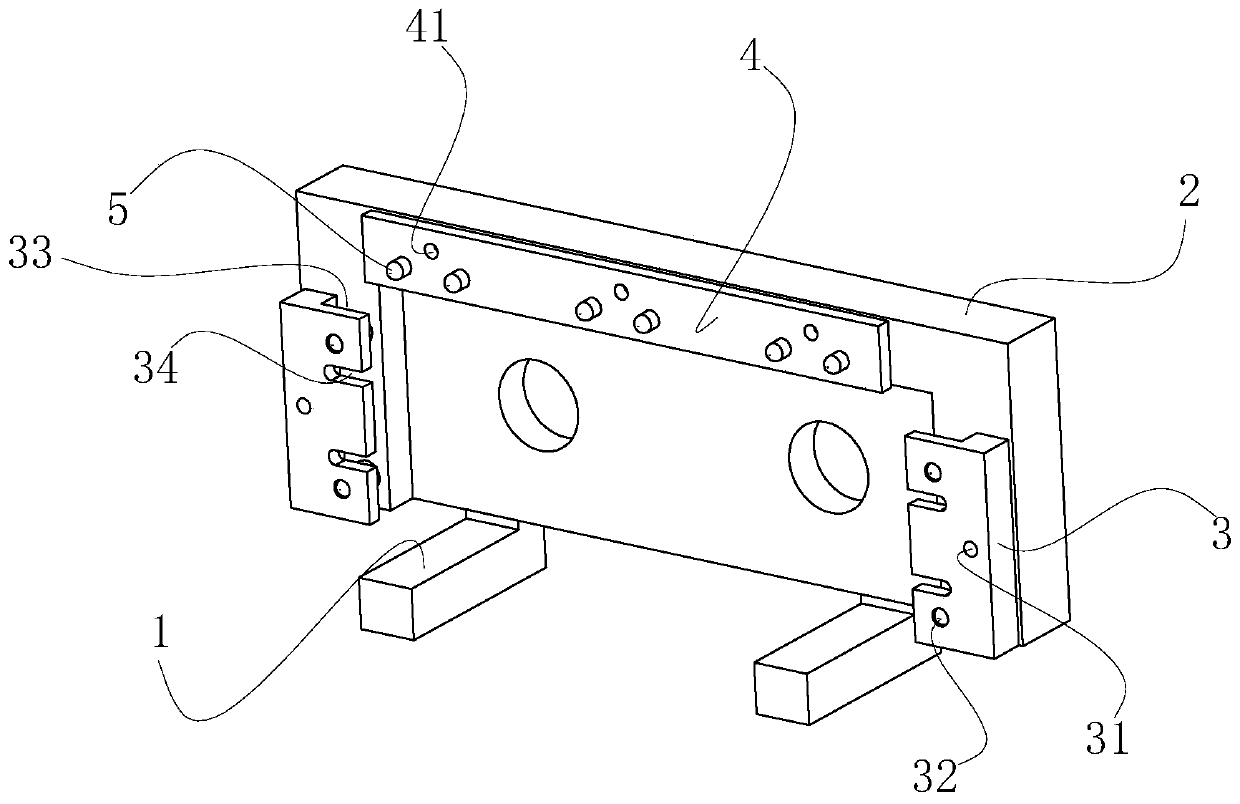

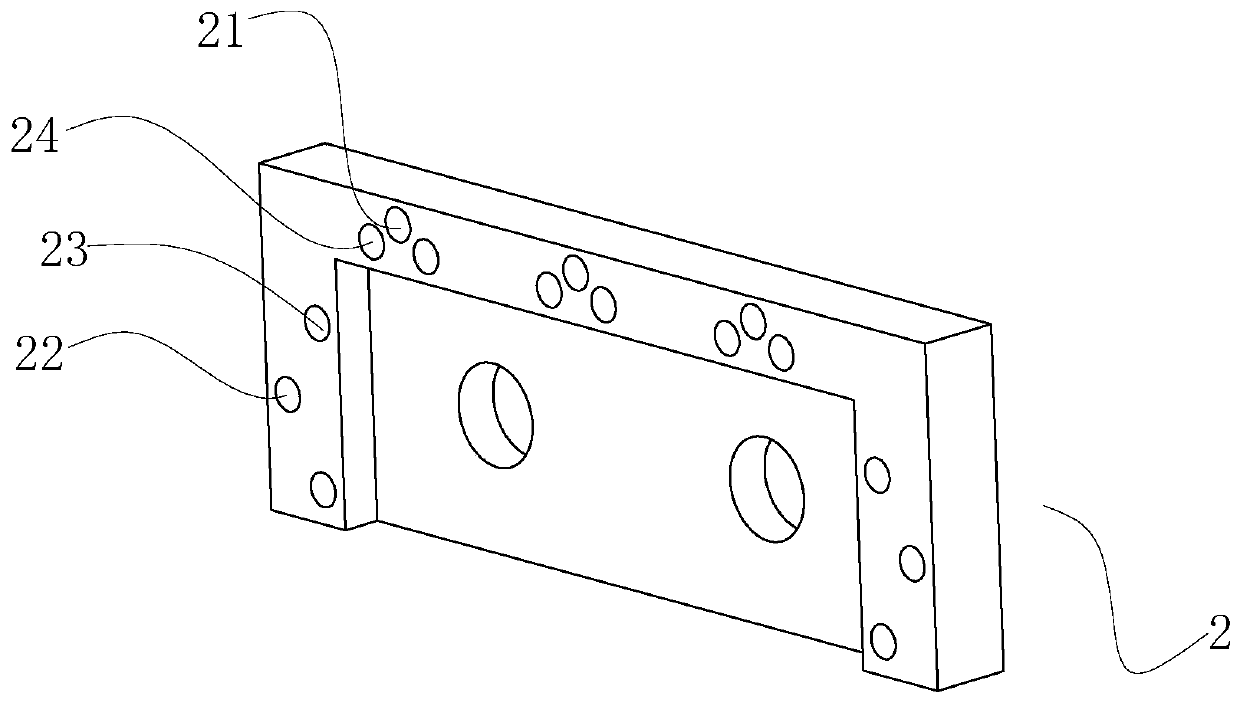

[0025] See figure 1 with figure 2 , The new energy vehicle capacitor potting tooling of this embodiment includes a foot 1 , a back plate 2 , a housing pressure plate 3 , an electrode pressure plate 4 and a fixing member 5 .

[0026] The main body of support foot 1 is cuboid shape, and support foot 1 has t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com