Vehicle-mounted camera module connector including positioning structure and assembly method thereof

A vehicle-mounted camera and positioning structure technology, which is applied in the direction of vehicle connectors, two-part connecting devices, and parts of connecting devices, can solve the problems of poor concentricity between the board-end connector and the shell, poor reliability, and obvious shortcomings, etc., to achieve Solve the effect of poor concentricity, reduce existing stress and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

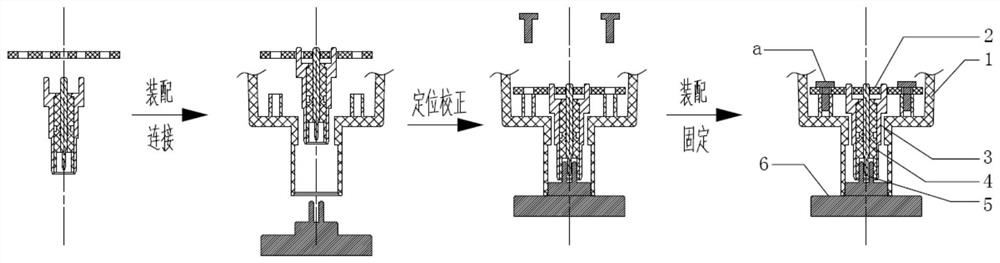

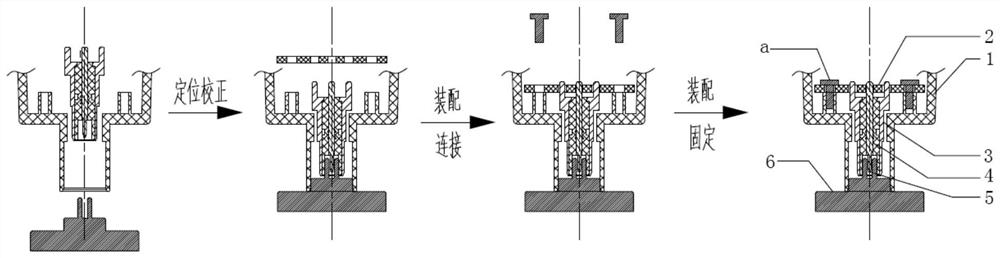

Embodiment approach

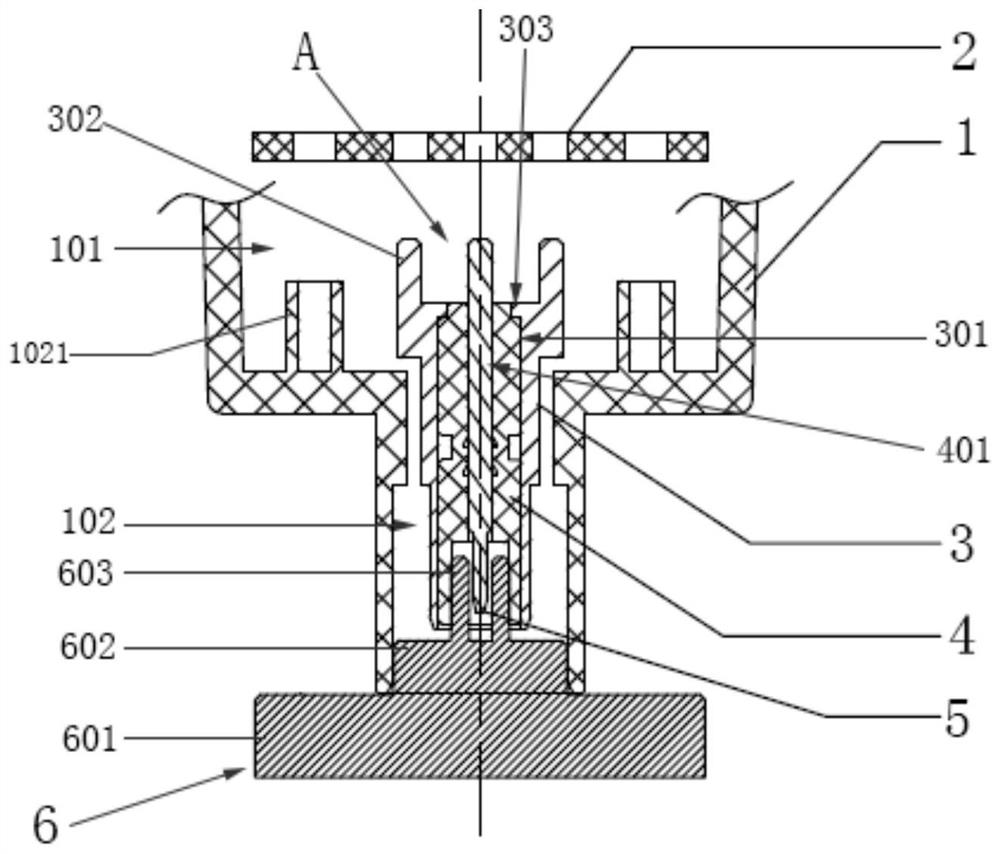

[0049] According to one embodiment of the present invention, the housing 1 includes a first cavity 101 and a second cavity 102, both of which are cylindrical structures in the present invention, wherein the first cavity 101 The inner diameter is larger than the second cavity 102 . The first cavity 101 is used for connecting the vehicle camera module, and the second cavity 102 is used for connecting the vehicle connector. The bottom of the first cavity 101 is provided with a fixing seat 1021 vertically extending upwards for fixing the circuit board 2 .

[0050] According to one embodiment of the present invention, the circuit board 2 is a flat structure, supported on the fixing seat 1021 at the bottom of the first cavity 101, and then fixed by screws a, or fixed by welding, riveting or glueing. .

[0051] According to an embodiment of the present invention, the board end connector A penetrates the first cavity 101 and the second cavity 102, and is fixedly connected to the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com