Patents

Literature

32results about How to "Improve long-term use stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

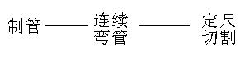

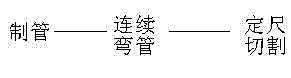

Production process and production line for continuous stainless steel coil

ActiveCN101797602ABeautiful appearanceUniform and bright colorProduction lineUltimate tensile strength

The invention relates to the machining for a stainless steel coil of a heat exchanging pipe. A production process for a continuous stainless steel coil comprises a pipe making step, a pipe bending step and a cutting step which adopt continuous on-line machining, wherein the first pipe making step comprises the following step: using a steel band as a raw material to perform on-line continuous pipe making; the second pipe bending step comprises the following steps: conveying an obtained steel pipe into a pipe bending machine; conveying a bent pipe to a second pipe bending position to bend the bent pipe for a second time; continuously bending the pipe in turn until the steel pipe is bent and assumes a single continuous bent pipe; and the third cutting step comprises the following step: sizing the single continuous bent pipe and cutting pipe end excess materials to obtain a single coil single pipe with a length of between 15 and 133 meters without a radial weld joint. The production process has the advantages of low cost, continuous pipe making and pipe bending and convenient machining, assembling and transportation. The obtained stainless steel coil has few or no radial welding spot, strong corrosion resistance without stress corrosion or corrosive pitting phenomenon, stable mechanical strength and relatively better heat exchanging efficiency.

Owner:BAC DALIAN

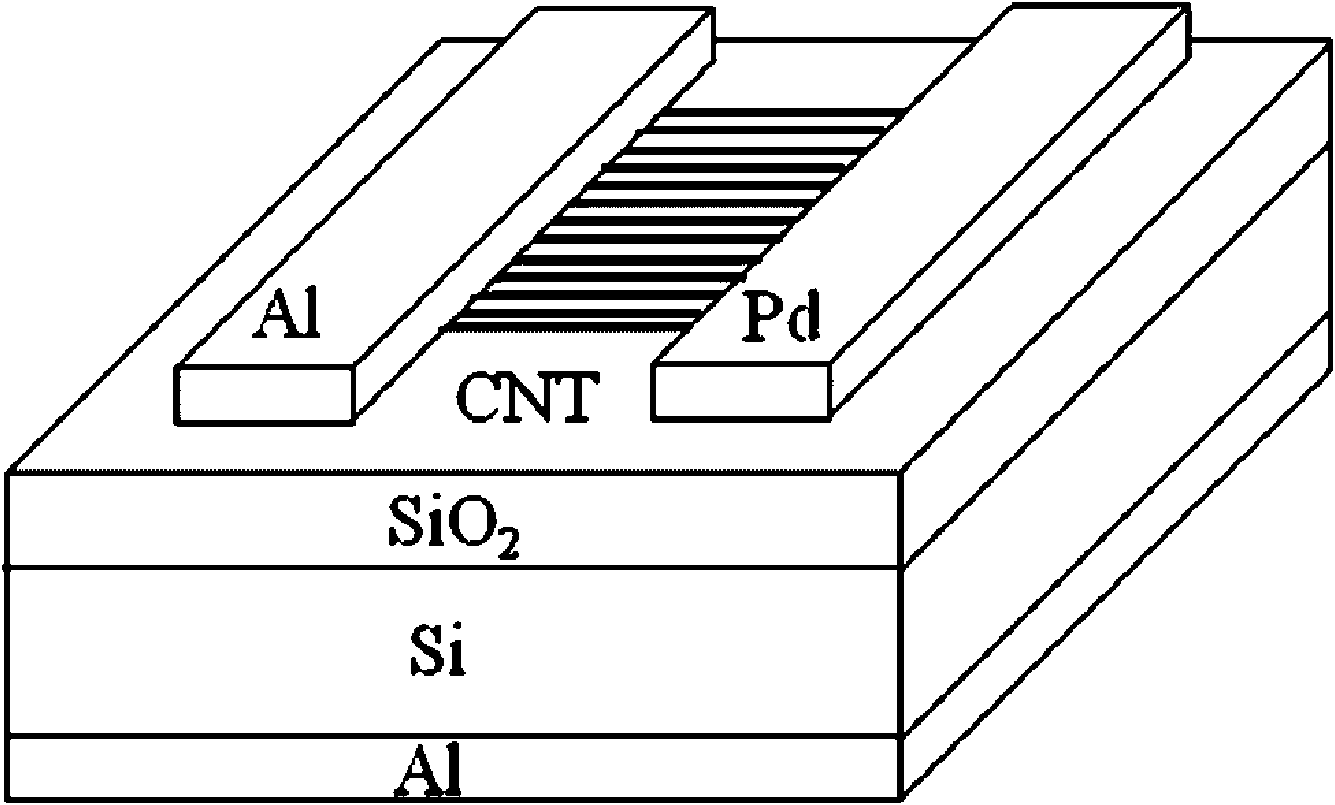

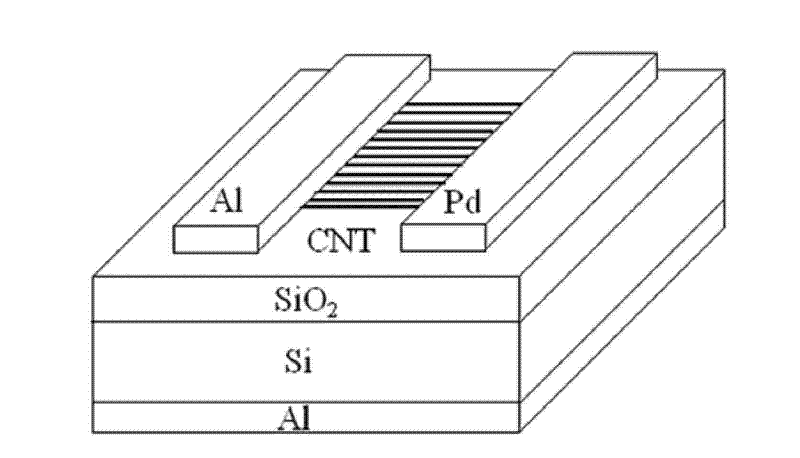

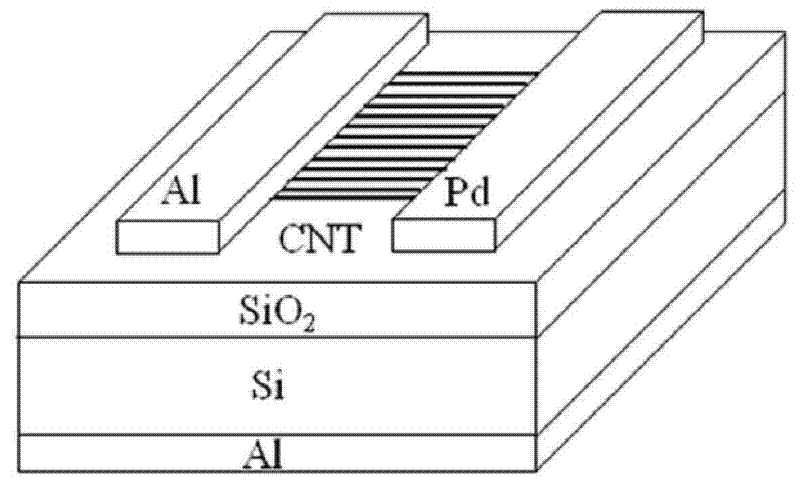

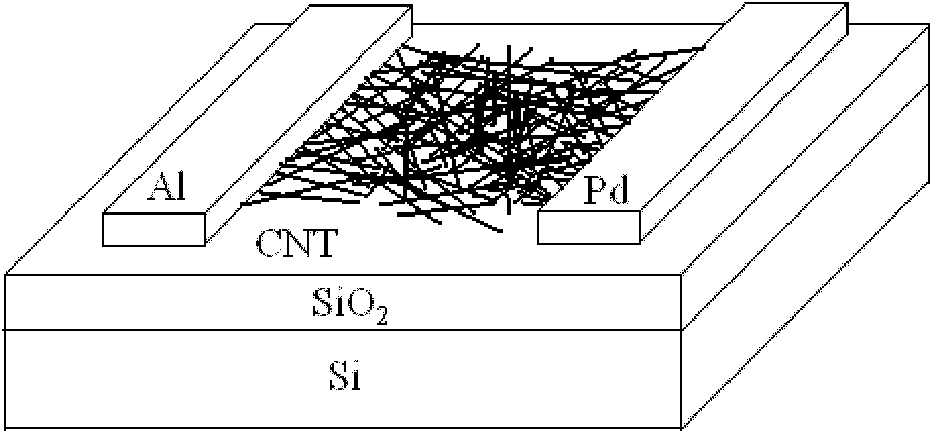

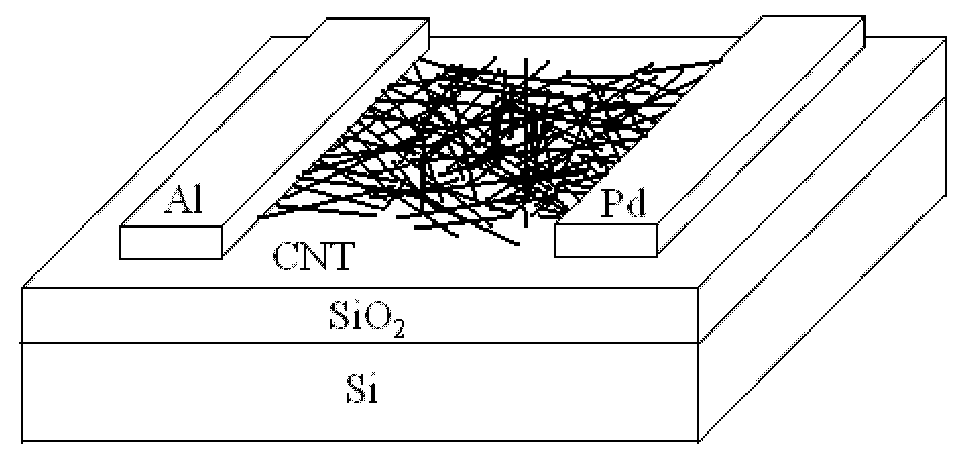

Preparation method of solar micro battery on basis of directional carbon nano tube

InactiveCN101667611ASimple structureImprove long-term use stabilityFinal product manufactureSemiconductor devicesNon symmetricCarbon nanotube

The invention relates to a preparation method of a solar micro battery on the basis of a directional carbon nano tube in the technical field of solar batteries, comprising: dispersing the carbon nanotube into an organic solvent by ultrasound to form stably dispersed carbon nano tube suspension liquid; making two asymmetry metal electrode couple respectively with high-power function and low-powerfunction at a substrate by adopting lithography; applying alternating bias voltage to the asymmetry metal electrode couple, dripping the carbon nano tube suspension liquid on the two electrodes so asto lead the carbon nano tube to from the directional carbon nano tube between the asymmetry electrodes under the action of dimensional electrophoresis force; and adopting high-current selective burnout method or methane plasma selectivity etching method to remove metallic carbon nano tube in the directional carbon nano tube, thus obtaining the solar micro battery. The micro battery is simple in structure and high in stability for long-term use, and can generate high open circuit voltage and efficiency.

Owner:SHANGHAI JIAO TONG UNIV

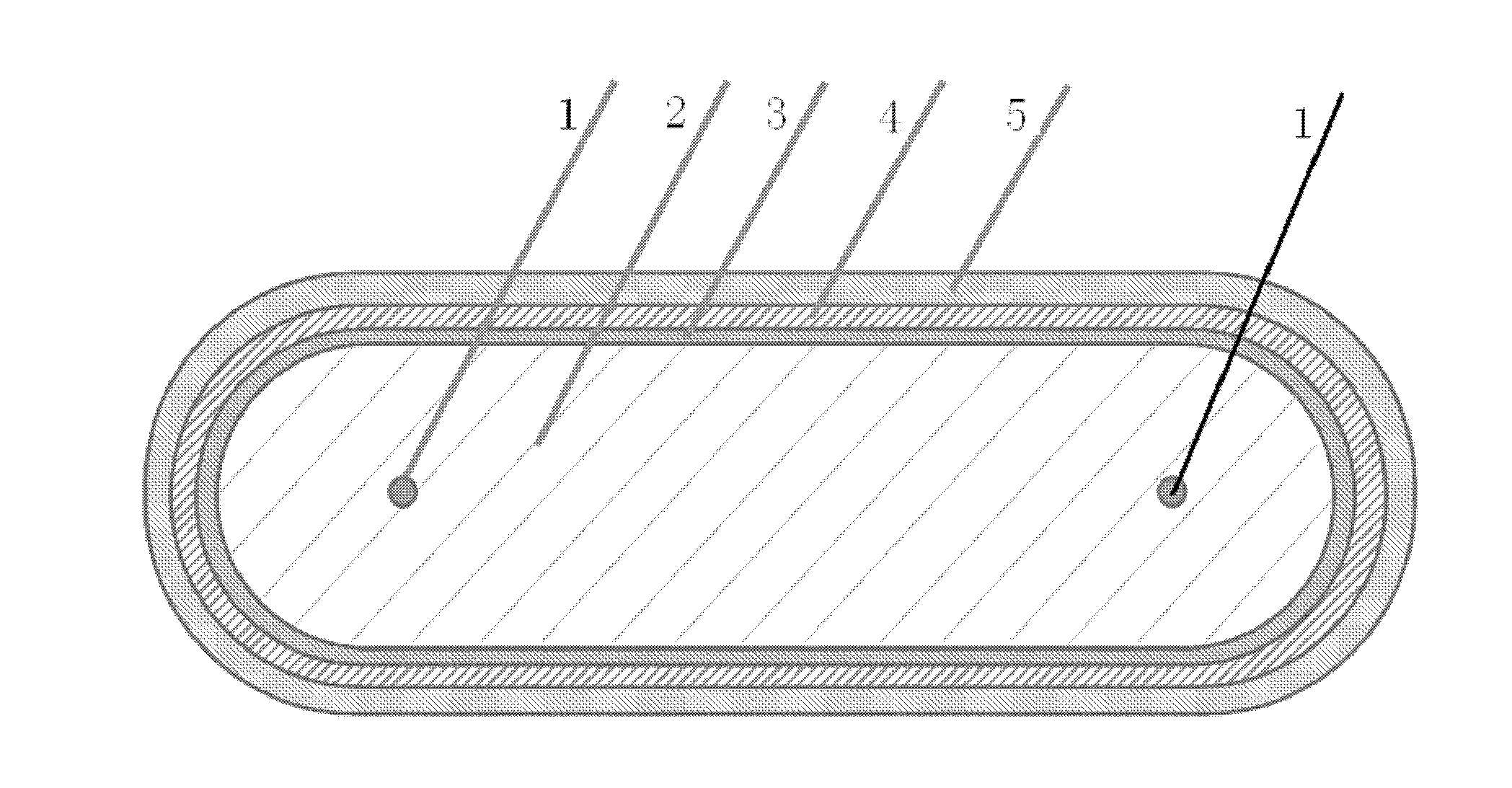

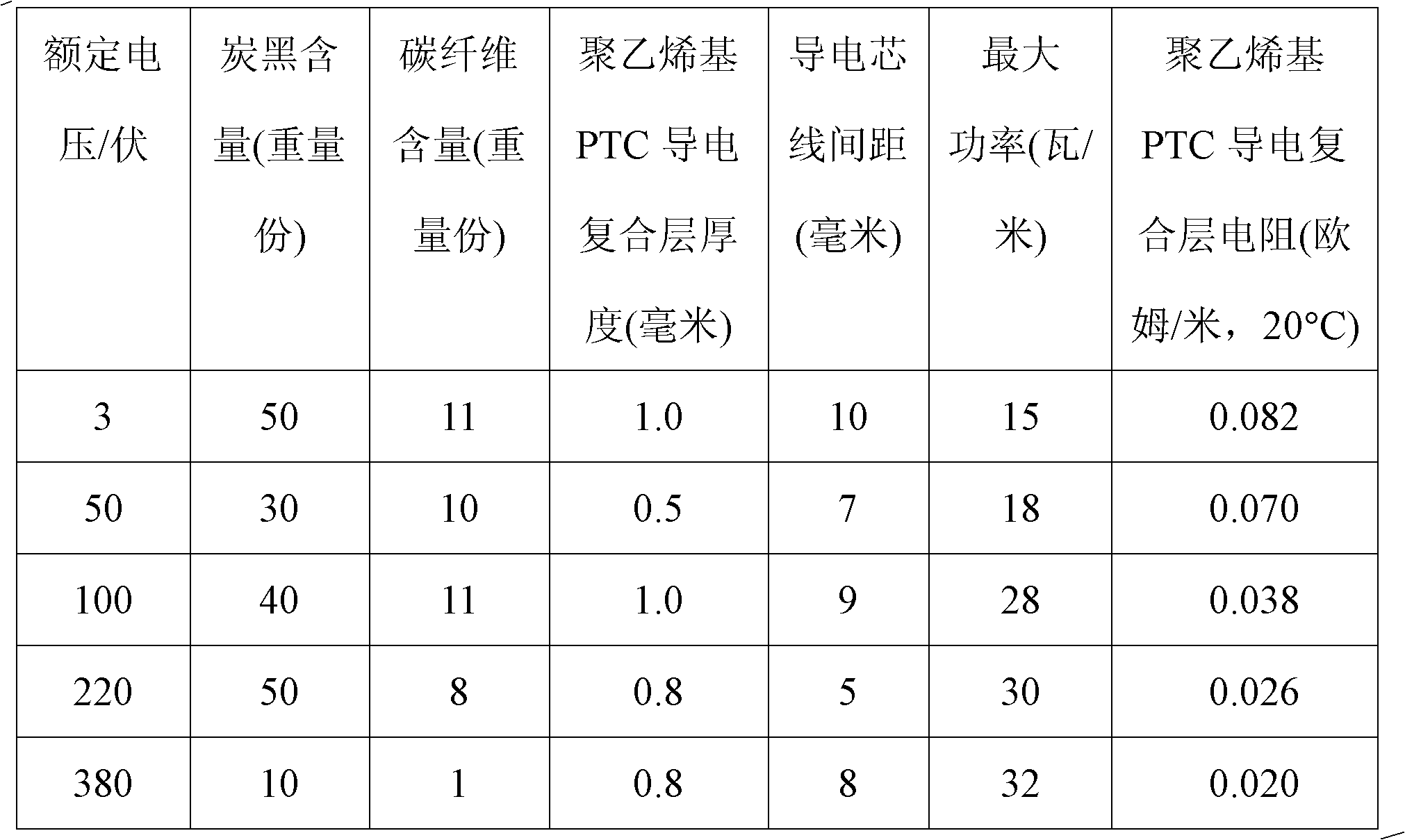

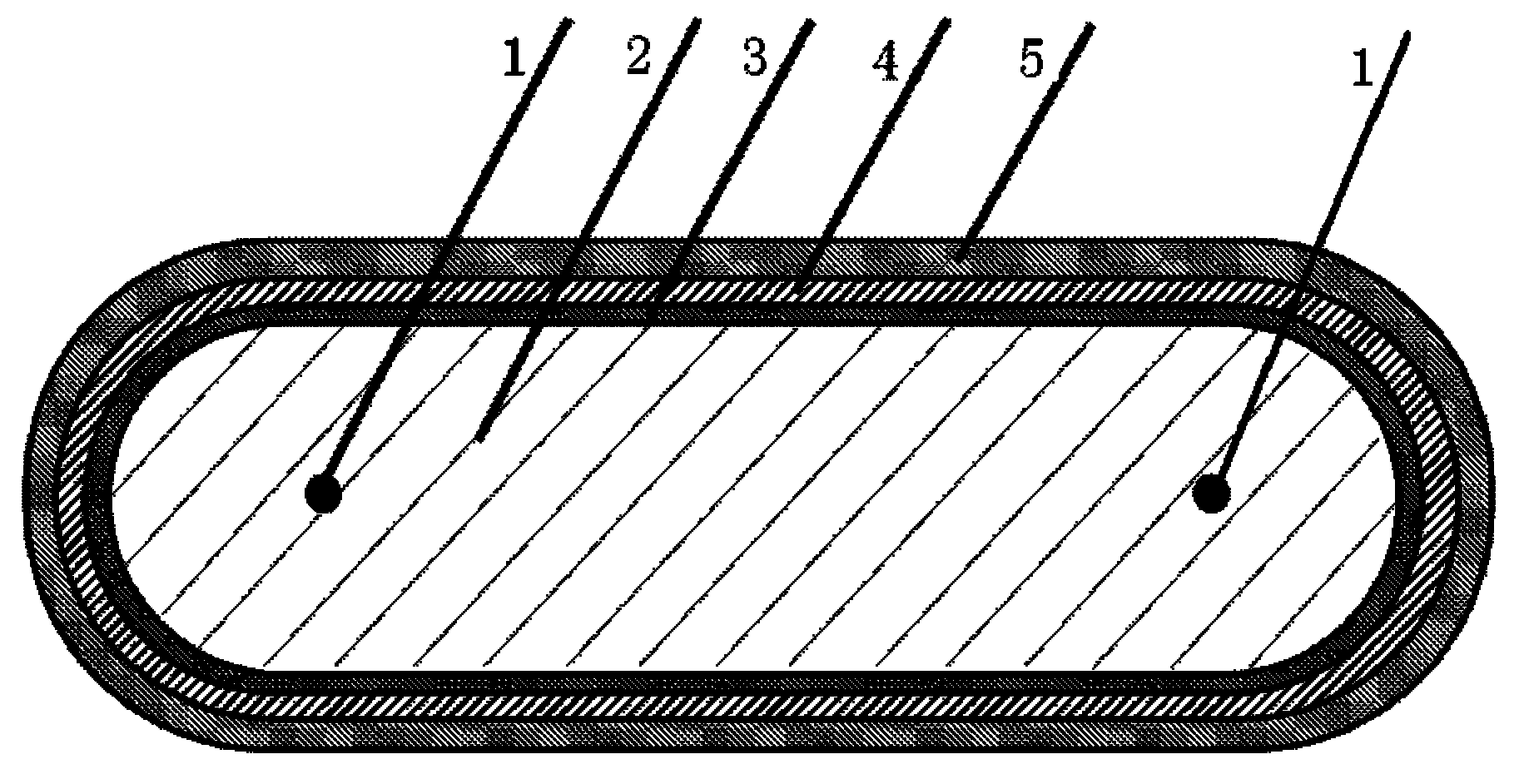

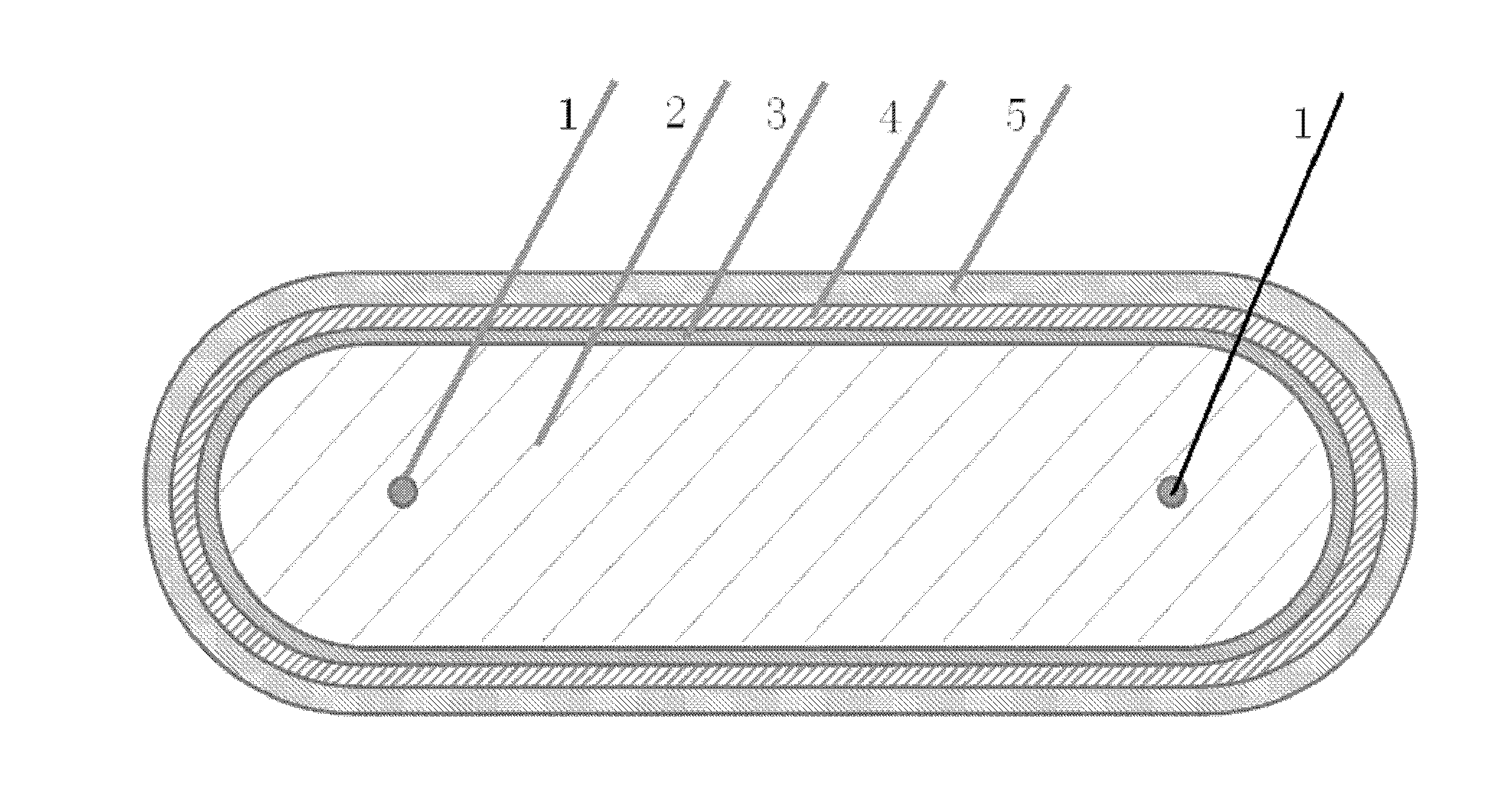

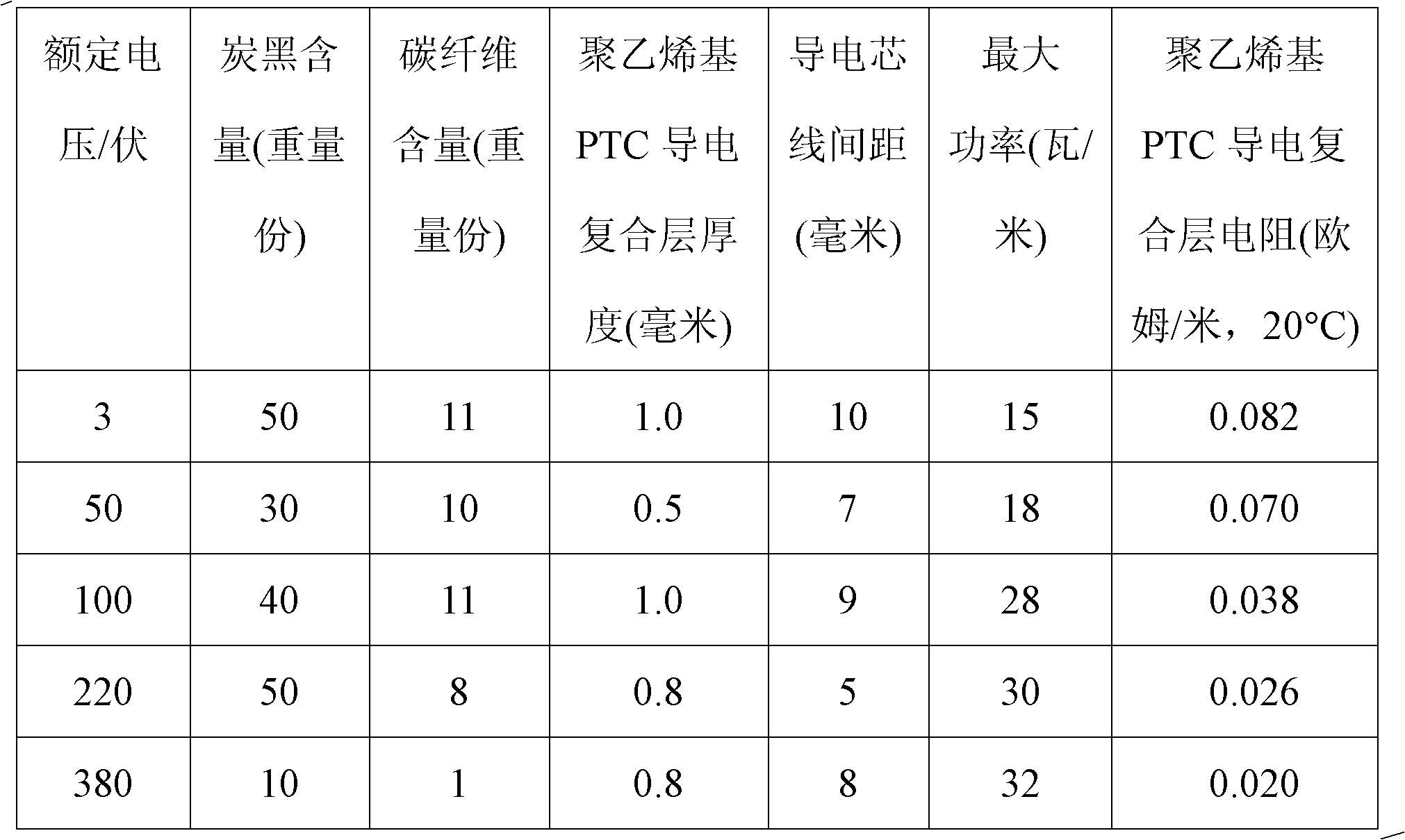

Self temperature limiting heat tracing strip of PTC (positive temperature coefficient) high polymer conductive composite material and preparation method thereof

InactiveCN102573154AImprove wettabilityGood dispersionHeating element shapesHeating element materialsPositive temperatureExtrusion coating

The invention discloses a self temperature limiting heat tracing strip of a PTC (positive temperature coefficient) high polymer conductive composite material, which comprises a flat strip that comprises a polyethylene PTC conductive complex layer. Two conductive core wires are extrusion coated inside the polyethylene PTC conductive complex layer. A polyethylene insulating layer, a shielding layer and a polyethylene reinforced protective layer closed in periphery are arranged orderly outside the polyethylene PTC conductive complex layer from inside to outside. The invention further discloses a preparation method of the self temperature limiting heat tracing strip, which comprises the steps of preparing the polyethylene PTC conductive complex layer; extrusion coating the two conductive core wires; and arranging the polyethylene insulating layer, the shielding layer and the polyethylene reinforced protective layer closed in periphery orderly outside the polyethylene PTC conductive layer from inside to outside. The self temperature limiting heat tracing strip provided by the invention will not generate bubbles, and is stable in electrothermal performance, safe and reliable. The preparation method provided by the invention has simple process flows and low cost, and is easy to realize.

Owner:XIAN GAIWO THERMAL ENERGY TECH

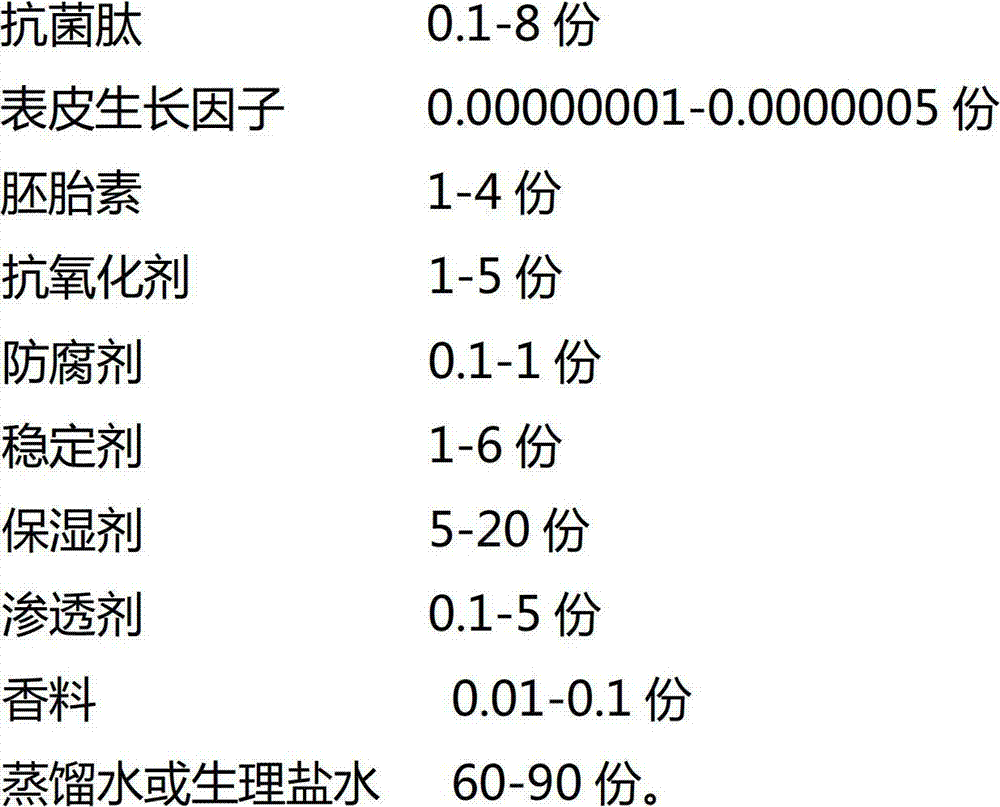

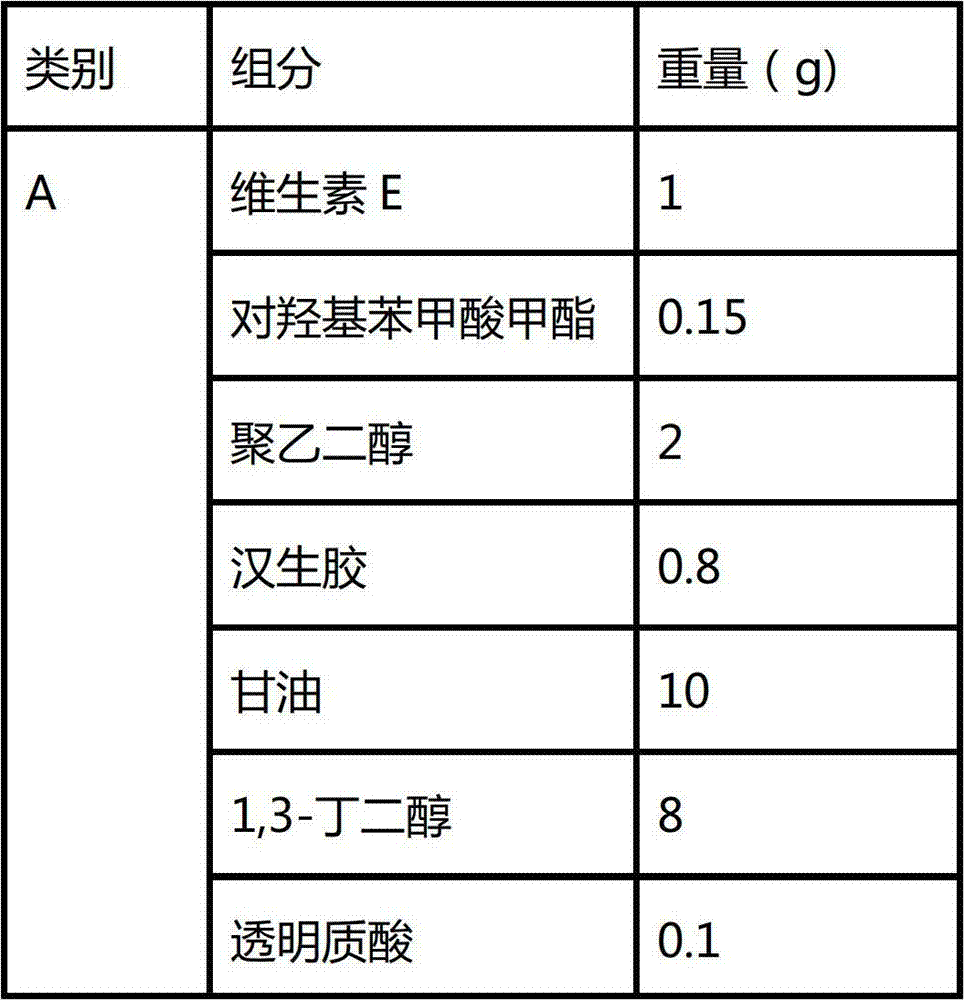

Antibacterial peptide skin care cosmetic

InactiveCN102824282AIncrease roughnessImprove dullnessCosmetic preparationsToilet preparationsFlavorCuticle

The invention discloses an antibacterial peptide skin care cosmetic which comprises the following components by weight: 0.1-8 parts of antibacterial peptides, 0.00000001-0.0000005 part of epidermal growth factors, 1-4 parts of embryosin, 1-5 parts of anti-oxidants, 0.1-1 part of preservatives, 1-6 parts of stabilizing agents, 5-20 parts of humectants, 0.1-5 parts of penetrating agents, 0.01-0.1 part of perfume, and 60-90 parts of distilled water or normal saline. The invention relates to the technical field of cosmetics, has high stability, and strong permeability, contains antibacterial factors, and has good skin care effect.

Owner:广州市华桑生物工程有限公司

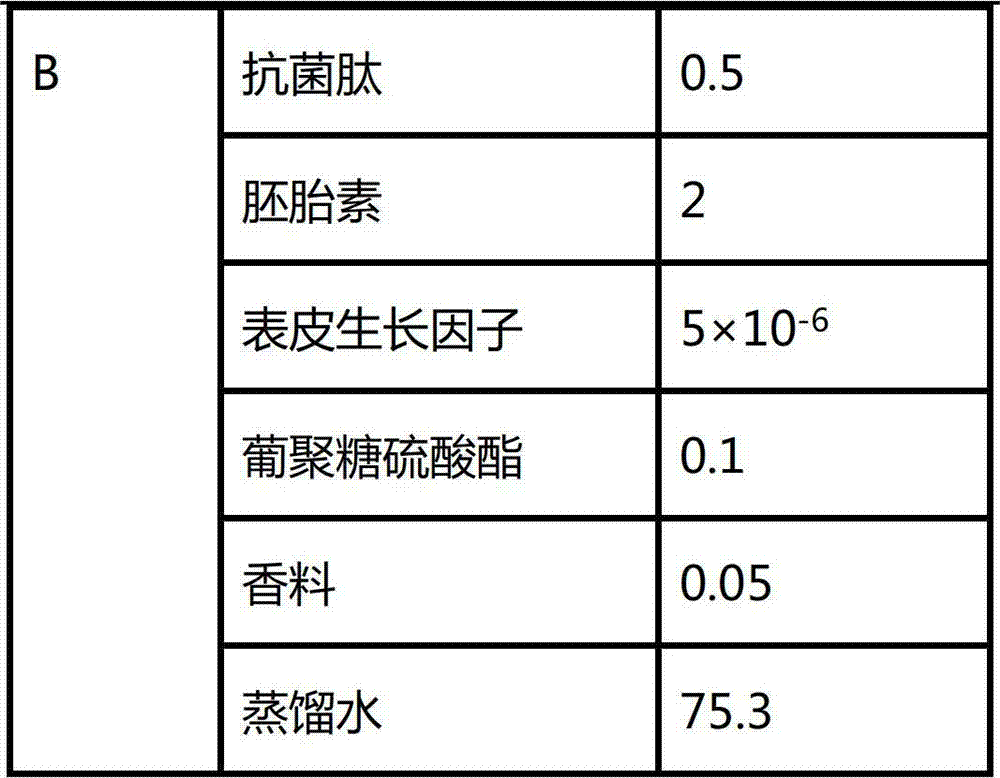

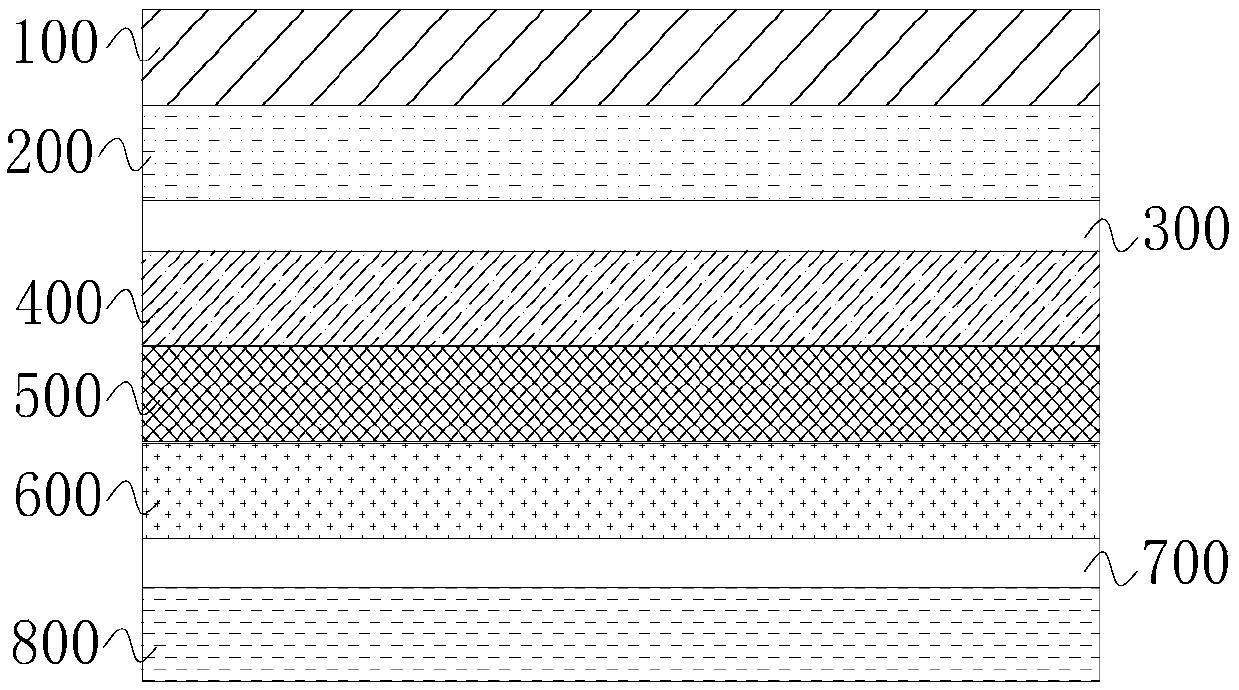

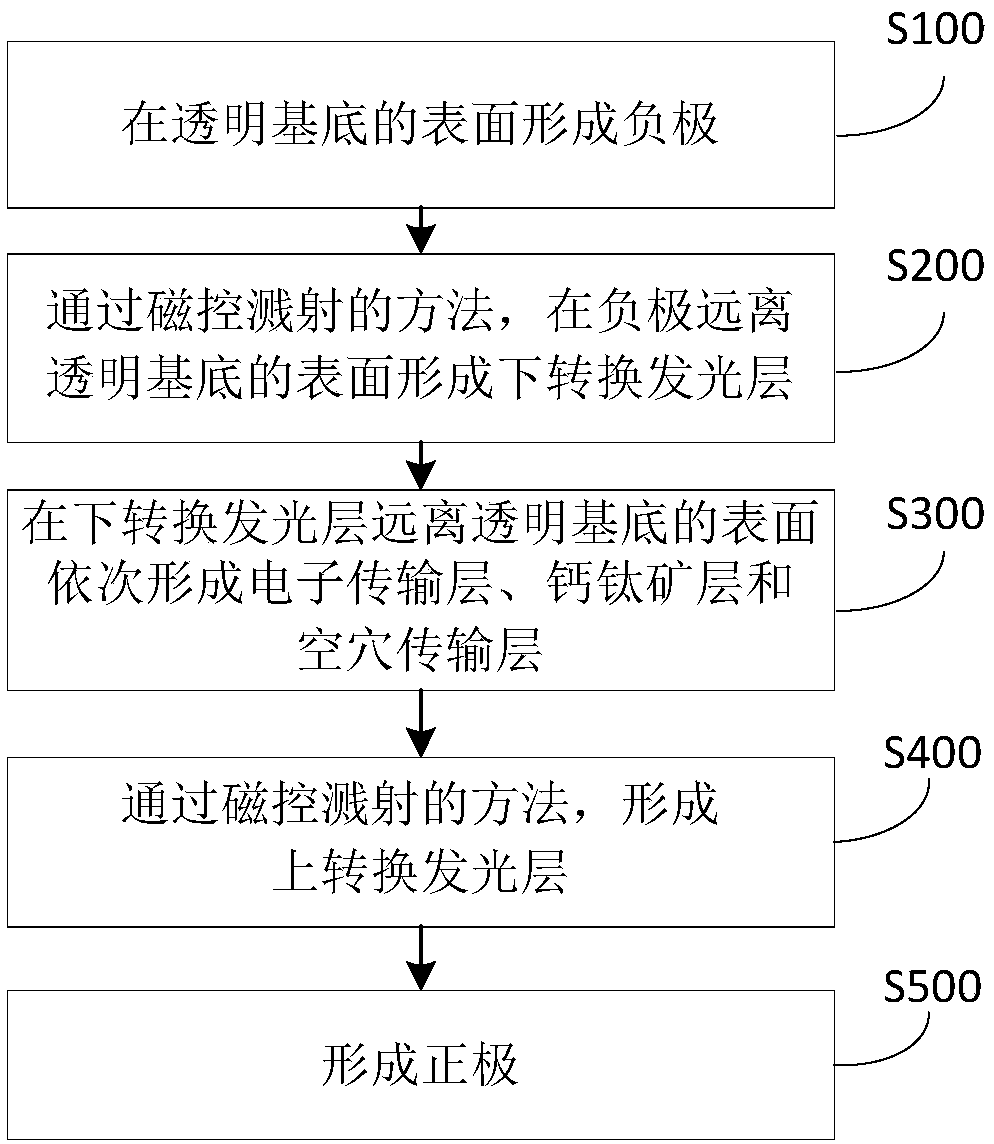

Perovskite solar cell and preparation method thereof

InactiveCN109671847AImprove photoelectric conversion efficiencyImprove long-term use stabilitySolid-state devicesSemiconductor/solid-state device manufacturingUpconversion luminescencePerovskite solar cell

The invention provides a perovskite solar cell and a preparation method thereof. The perovskite solar cell comprises a transparent substrate arranged in a stacked layer, a negative electrode, a down-conversion luminescent layer, an electron transfer layer, a perovskite layer, a hole transport layer, an up-conversion luminescent layer and a positive electrode, wherein the down-conversion luminescent layer is arranged between the negative electrode and the electron transport layer. The perovskite solar cell has the advantages that the down-conversion luminescent layer and the up-conversion luminescent layer are respectively additionally arranged on the upper surface and the lower surface of the perovskite solar cell, so that ultraviolet light and infrared light which cannot be absorbed by the perovskite solar cell can be converted into visible light, the utilization rate of sunlight is increased, the photoelectric conversion efficiency of the perovskite solar cell is further improved, and the long-term stability of the solar cell can be enhanced.

Owner:WUXI UTMOST LIGHT TECH CO LTD

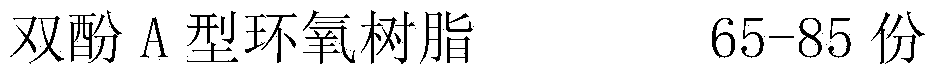

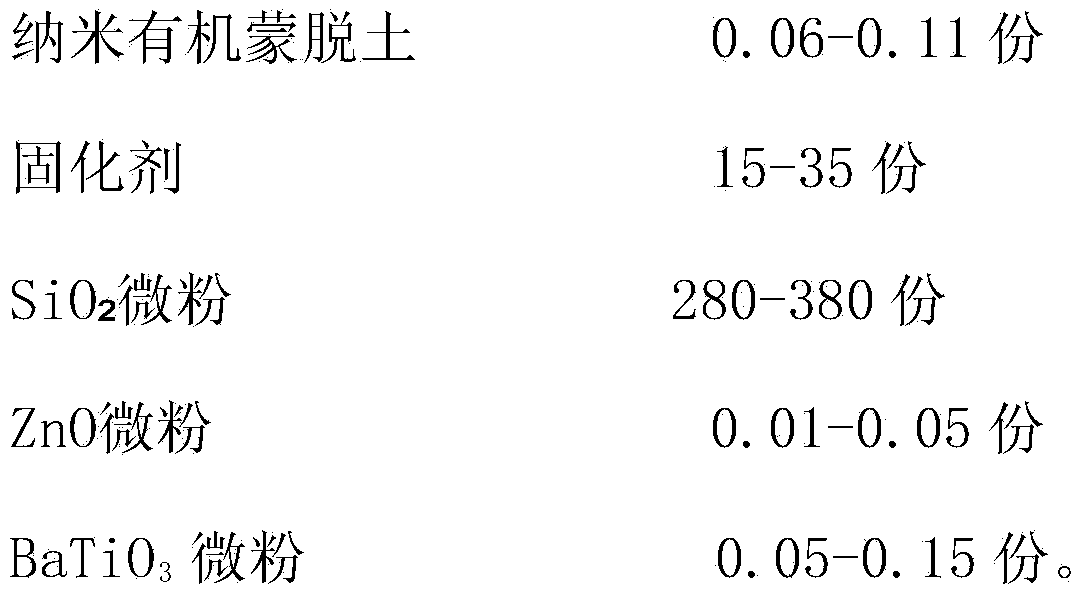

Insulating material for bus and preparation method thereof

ActiveCN103834141AImprove operational reliabilitySatisfy partial dischargeTransformerPower equipment

The invention relates to an insulating material for bus, which comprises the following components by weight: 65-85 parts of bisphenol A-type epoxy resin, 0.06-0.11 part of nanometer organic montmorillonite, 15-35 parts of a curing agent, 280-380 parts of SiO2 micro powder, 0.01-0.05 part of ZnO micro powder, and 0.05-0.15 part of BaTiO3 micro powder. The insulating material of the invention can operate under awful weather conditions, is widely applicable to power plants, power stations, transformer substations, photovoltaic power stations, wind power generation transformer substations, is an important accessory for power transmission equipment, is an important material for processing high voltage electric power matching insulating parts, and has good insulating properties and water resistance. The invention also provides a preparation method of the insulating material.

Owner:江苏华联天晴电力器材有限公司

Organic silicon electronic pouring sealant with good ultraviolet-resisting cooling performance for PCB (Printed Circuit Board)

InactiveCN106634814AHigh tensile strengthSmall molecular weightNon-macromolecular adhesive additivesMacromolecular adhesive additivesIonSilicone resin

The invention discloses an organic silicon electronic pouring sealant with good ultraviolet-resisting cooling performance for a PCB (Printed Circuit Board). The organic silicon electronic pouring sealant is prepared from the following raw materials in parts by weight: 40 to 50 parts of vinyl end silicone oil-1, 50 to 60 parts of vinyl end silicone oil-2, 0.38 to 0.5 part of 12 percent platinum catalyst, 0.02 to 0.04 part of ethynylcyclohexanol, 25 to 30 parts of vinyl silicone resin, 1-allyloxy-2, 14.8 to 16.8 parts of 3-epoxypropane 1, 23 to 25 parts of 1,3,5,7-tetramethylcyclotetrasiloxane, 2.7 to 3.6 parts of silane coupling agent A171, a proper amount of hydrogen-containing silicone oil, 3.4 to 4 parts of graphene, 0.2 to 0.4 part of silane coupling agent KH1510, a proper amount of acetone and a proper amount of deionized water. The pouring sealant prepared by the invention is simple in preparation process, wide in raw material source, high in operability and high in quality stability of a product; in addition, the pouring sealant has the advantages of excellent weather fastness, heat dissipation, corrosion resistance, high strength and the like, and is worthy of being popularized.

Owner:铜陵安博电路板有限公司

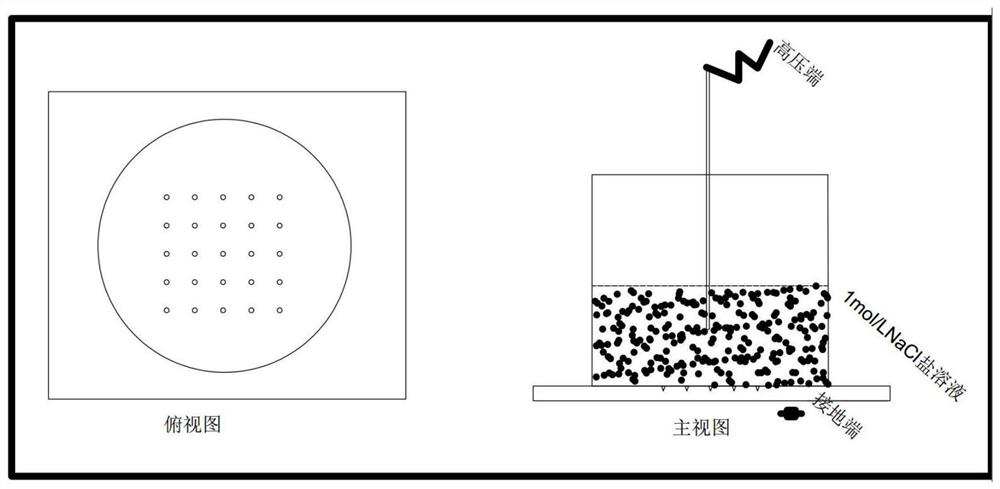

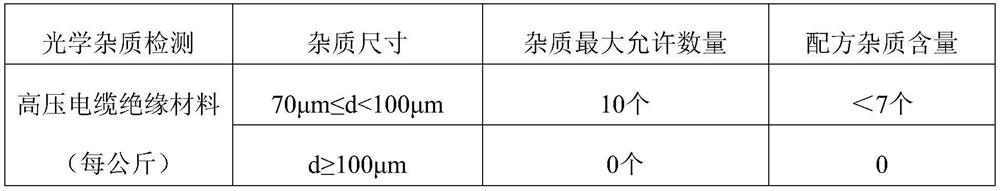

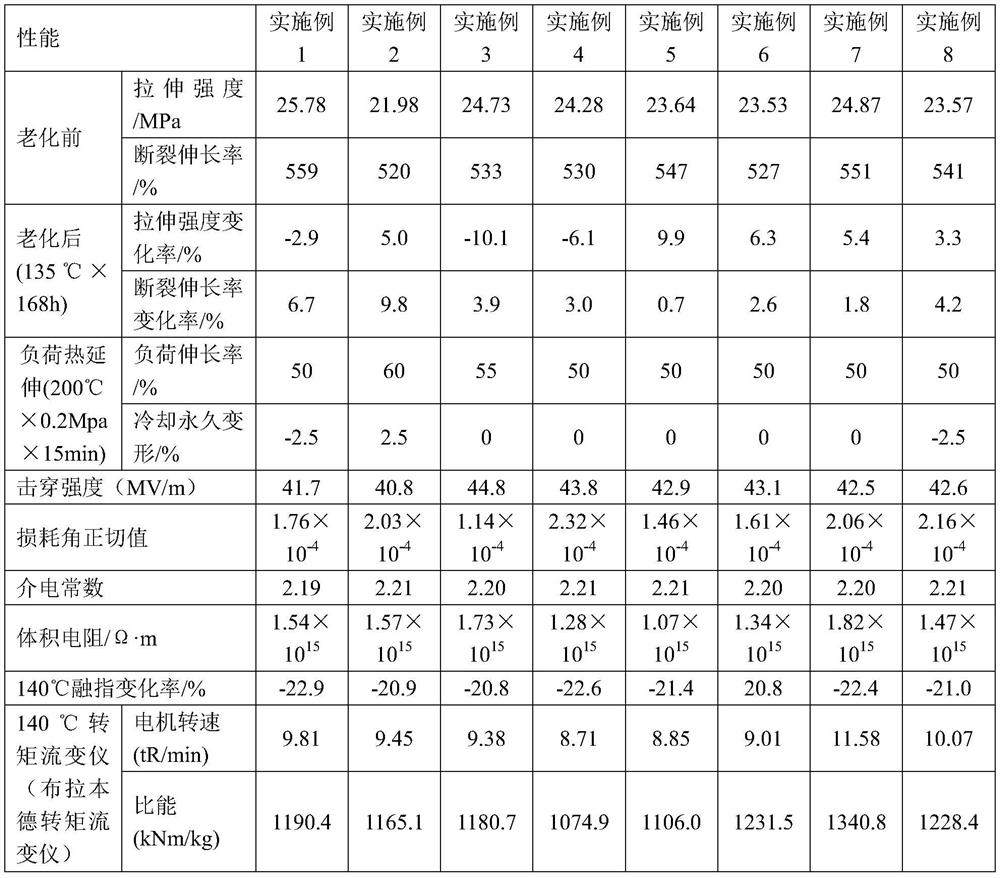

High-voltage cable insulating material and preparation method and application thereof

PendingCN111635569AImprove insulation performanceExcellent breakdown strength stabilityLow-density polyethyleneCross linker

The invention provides a high-voltage cable insulating material and a preparation method and application thereof. The high-voltage cable insulating material comprises the components in parts by weight: 100 parts of low density polyethylene; 0.1 to 0.3 part, preferably 0.15 to 0.20 part, of an antioxidant; 1.0 to 2.0 parts, preferably 1.0 to 1.5 parts, of a cross-linking agent; 0.5 to 5.0 parts, preferably 0.5 to 2.0 parts, of a polybutadiene auxiliary agent; and 0.5-10.0 parts, preferably 0.5-5.0 parts, of a high polymer material additive. The high-voltage cable insulating material disclosed by the invention is excellent in comprehensive insulating property; the high-voltage cable insulating material disclosed by the invention has excellent breakdown strength stability, and meanwhile, an excellent water-tree-resistant effect is obtained, so that the long-term use stability of the material can be obviously improved. Furthermore, the preparation method of the high-voltage cable insulating material can greatly reduce the use amount of the cross-linking agent, has lower processing energy consumption, effectively reduces the cost, is suitable for industrial long-time stable production,and indirectly shortens the degassing time.

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

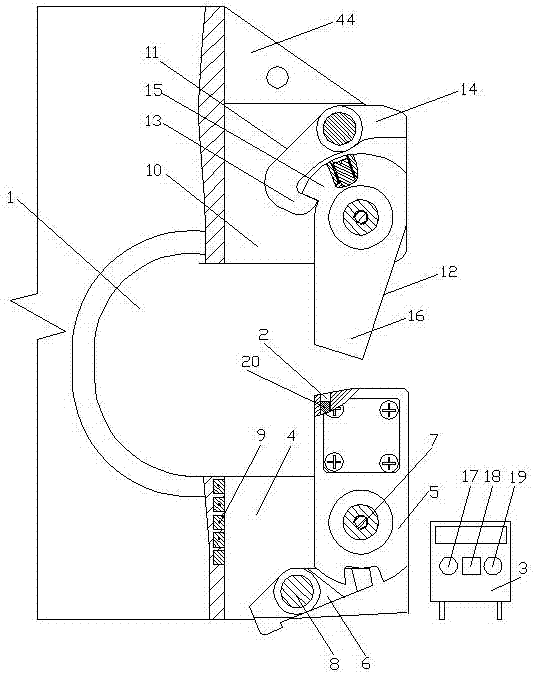

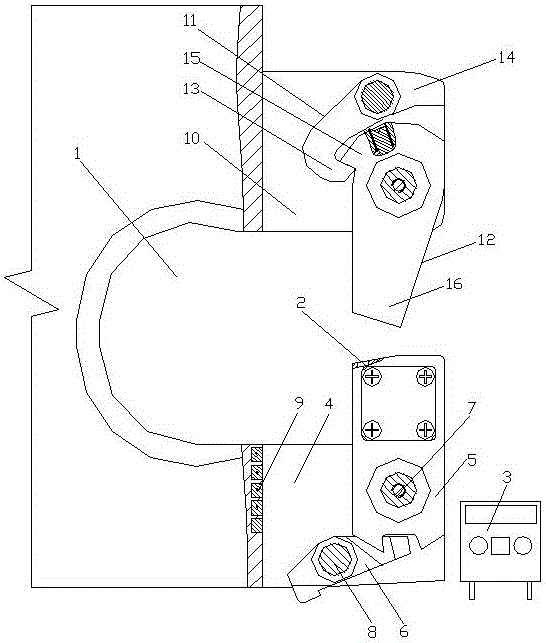

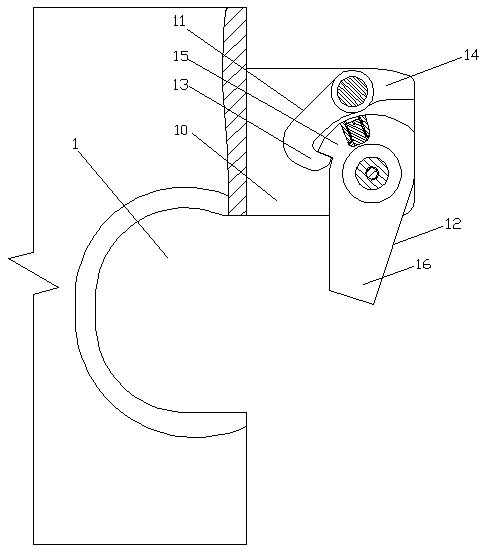

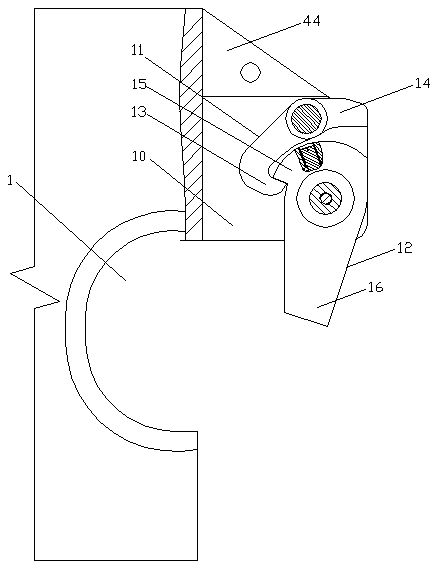

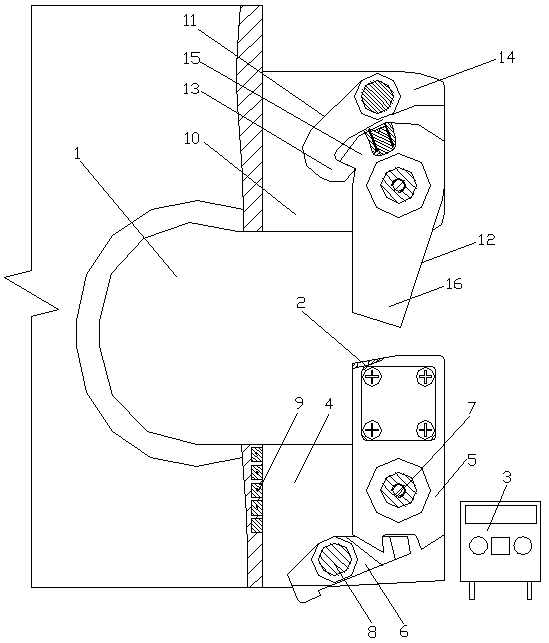

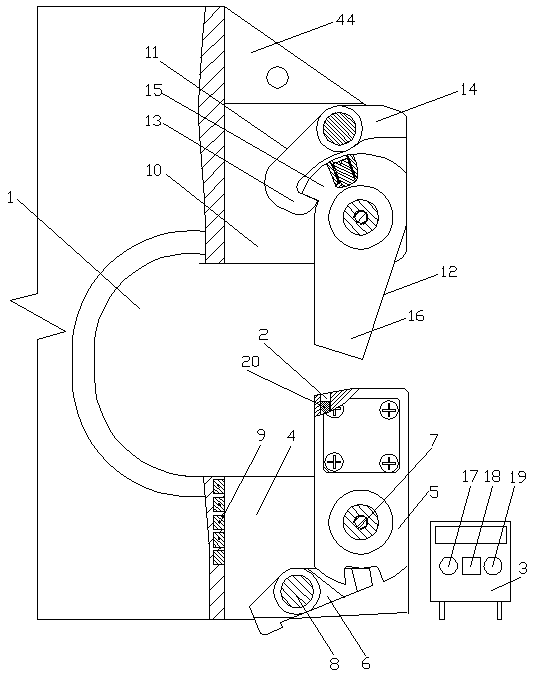

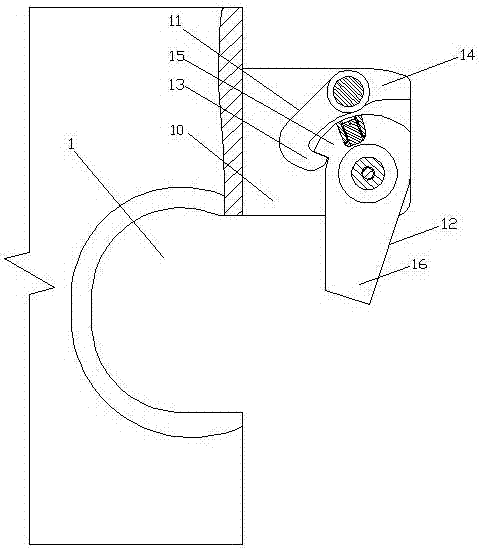

Method for preventing drop and hoisting of single hanging ring

The invention discloses a method for preventing drop and hoisting of a single hanging ring. The method comprises the steps that a, a drop preventing mechanism of a system for preventing drop and hoisting of the single hanging ring is opened and made to be in an unlocking state; b, when one of the hanging rings is mounted in the position, on one side of an elevator, of a lug hole of a lifting lug, an induction part of a drop preventing part sends a signal, after receiving the signal, a controller forbids moving of a runner wagon, the runner wagon is in a stop state, and after the hanging ring enters the lug hole, the drop preventing mechanism is in a locking state, and the hanging ring is blocked in the lug hole; and c, and the other hanging ring is mounted in the position, on the other side of the elevator, inside the lug hole of the lifting lug, the induction part of the drop preventing part sends a signal, and after receiving the signal, the controller allows the runner wagon to move. It can be effectively guaranteed that the two hanging rings both enter the lug hole, so that single hanging ring hoisting is avoided. Through the joint effect of the drop preventing mechanism and the drop preventing part, the hanging rings can be blocked firmly in the lug hole, slipping is avoided, the working stability and reliability of the elevator are improved, and the safety accident is eradicated.

Owner:CHENGDU ZHUOXIN IND

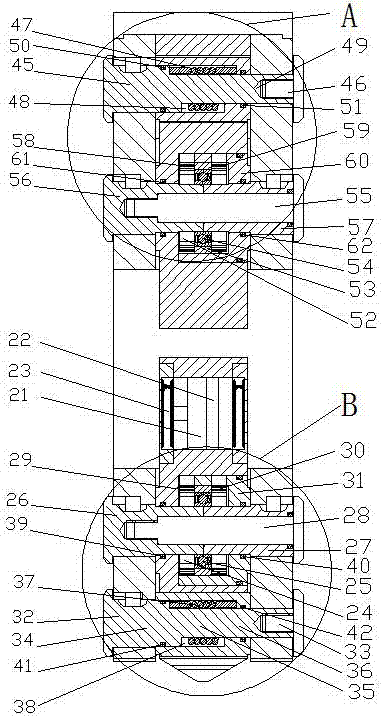

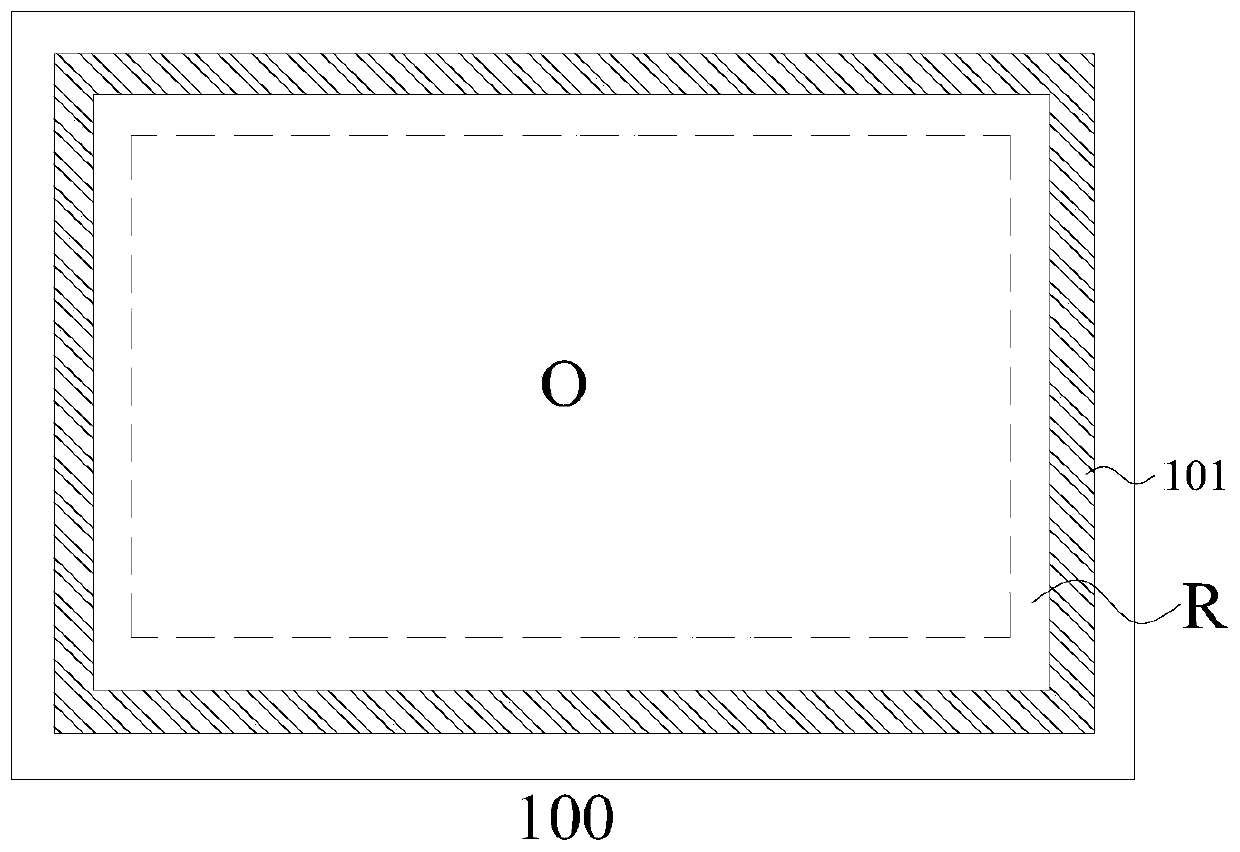

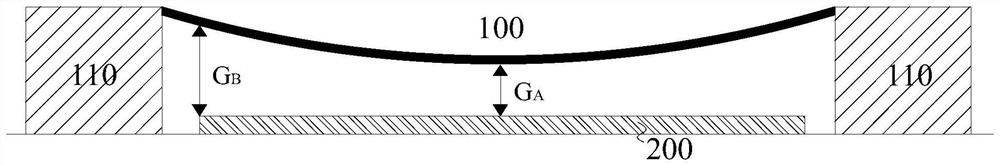

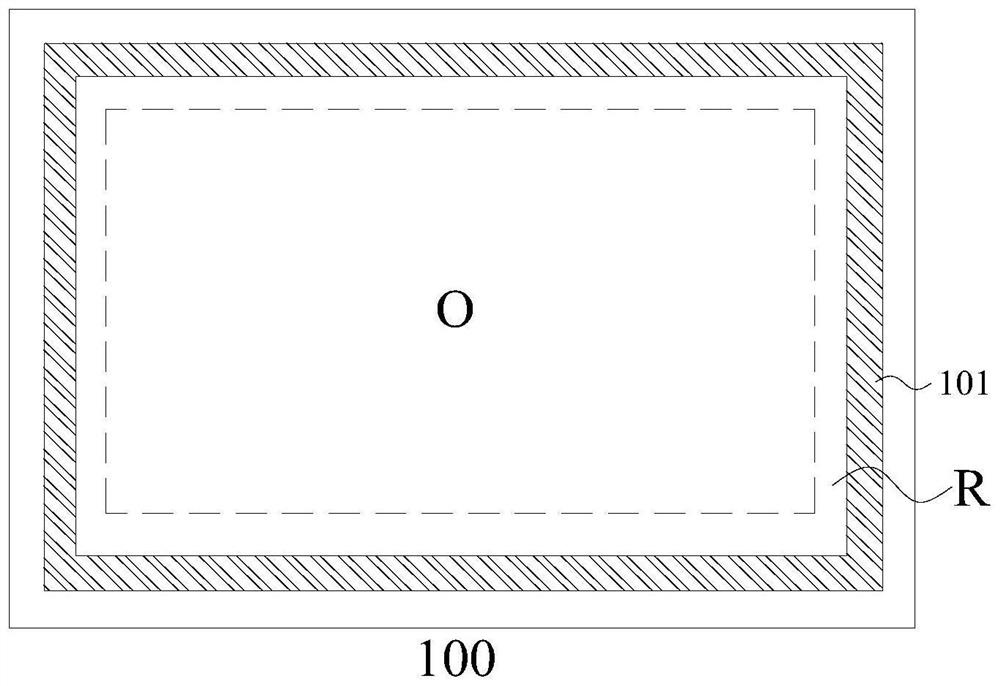

Metal mask, display panel and display device

ActiveCN110838565AImprove manufacturing yieldImprove thickness uniformityVacuum evaporation coatingSolid-state devicesDisplay devicePhysics

The invention provides a metal mask, a display panel and a display device. The metal mask plate comprises an opening area and a peripheral area, wherein the peripheral area is arranged around the opening area, the peripheral area is provided with a first half notch groove, and the first half notch groove is arranged around the opening area. According to the metal mask provided in the invention, byintroducing the first half notch groove arranged around the opening area into the peripheral area, the sagging amount of the metal mask can be effectively improved, and the net stretching force of the metal mask can be reduced, so that the thickness uniformity of an inorganic packaging layer formed by using the metal mask at different positions is improved, and the manufacturing yield of the display panel is higher.

Owner:BOE TECH GRP CO LTD +1

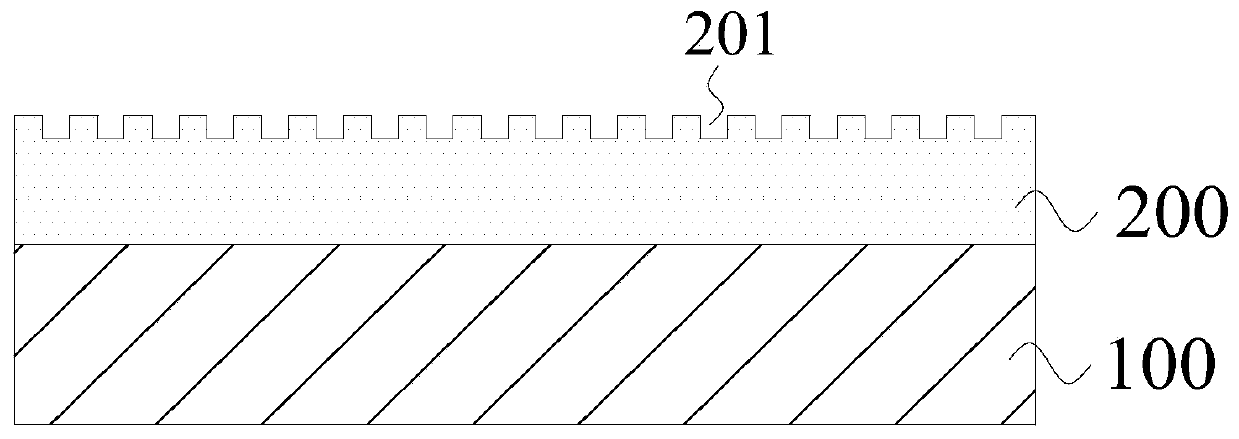

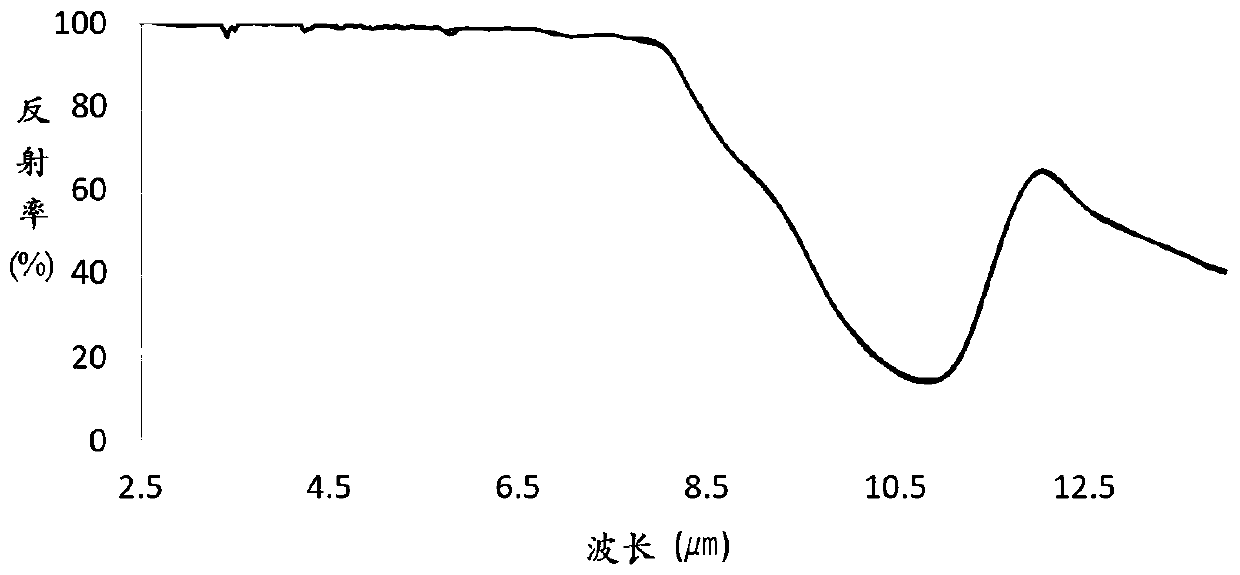

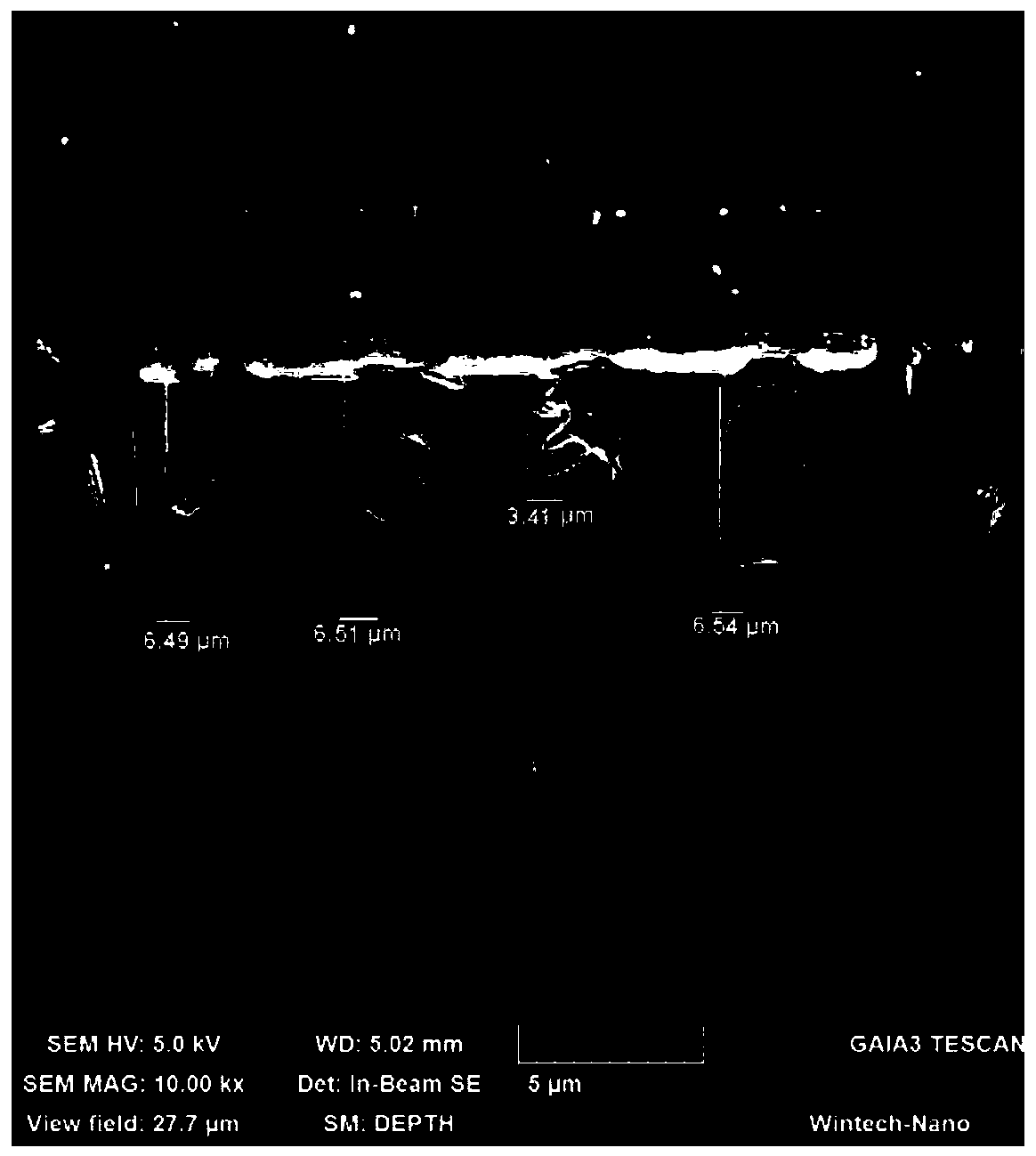

Cooling fin for display screen and electronic device

ActiveCN110602933ALow thermal conductivityIncrease the areaSolid-state devicesSemiconductor/solid-state device manufacturingThermal insulationGraphite

The application provides a cooling fin for a display screen and an electronic device. The cooling fin includes: a graphite sheet; and a thermal radiation adjusting film disposed on one surface of thegraphite sheet and provided with a plurality of micro-cavities on a surface away from the graphite sheet. In the cooling fin provided by the invention, the thermal radiation adjusting film is disposedon the upper surface of the graphite sheet, and the upper surface of the thermal radiation adjusting film has a plurality of micro-cavities. In this way, the area of the upper surface of the thermalradiation adjusting film that has a thermal insulation effect can be added, thereby reducing the heat conduction of the cooling fin in the thickness direction.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

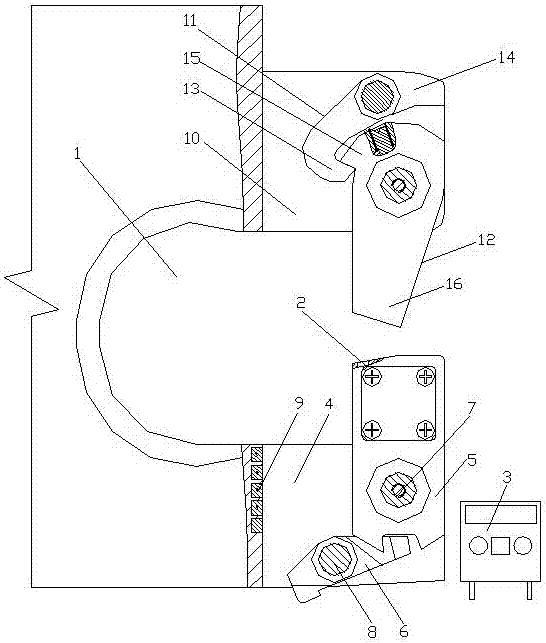

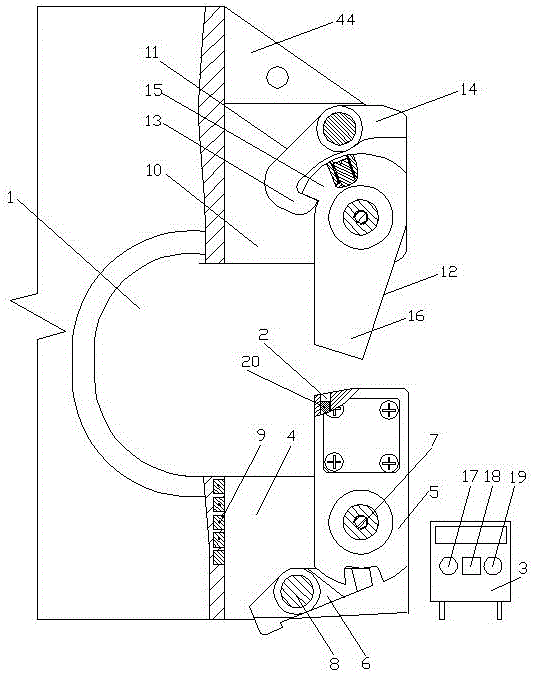

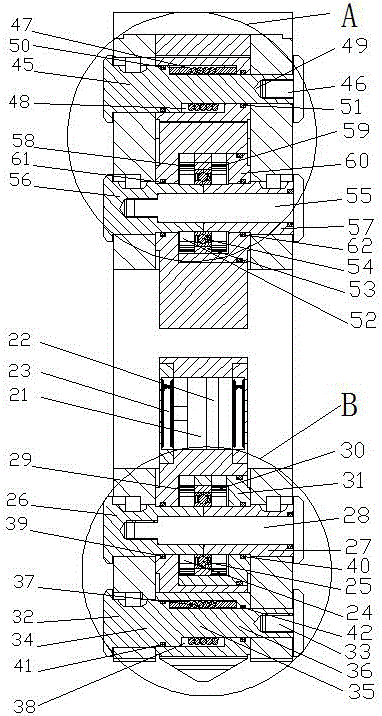

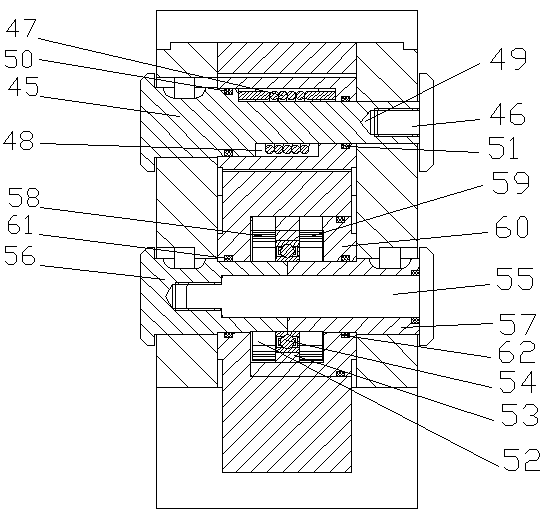

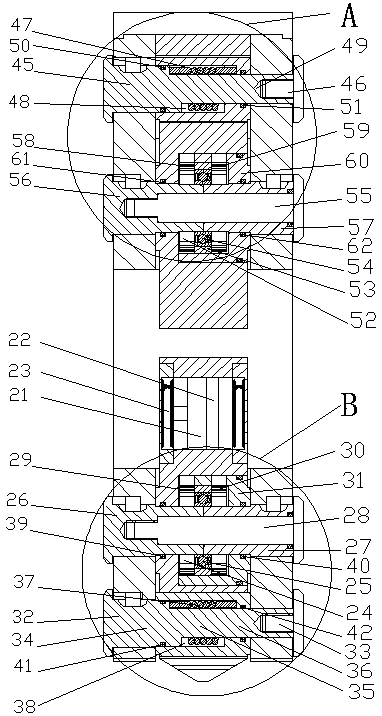

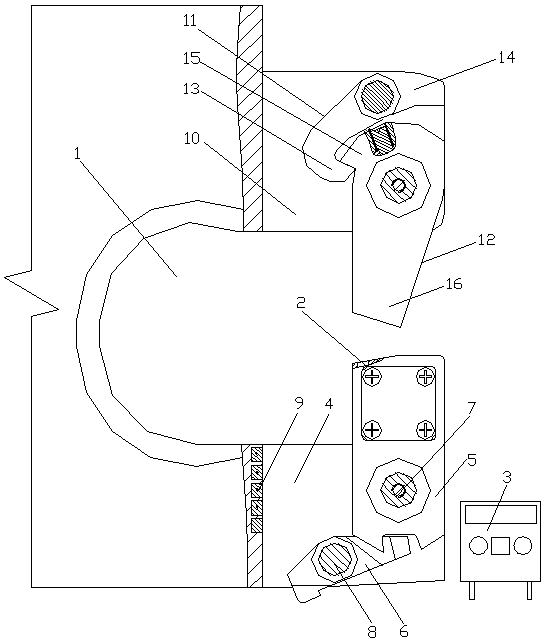

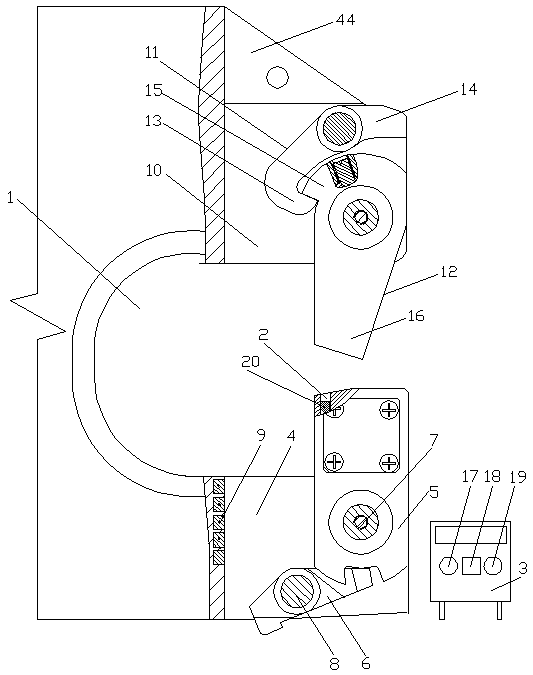

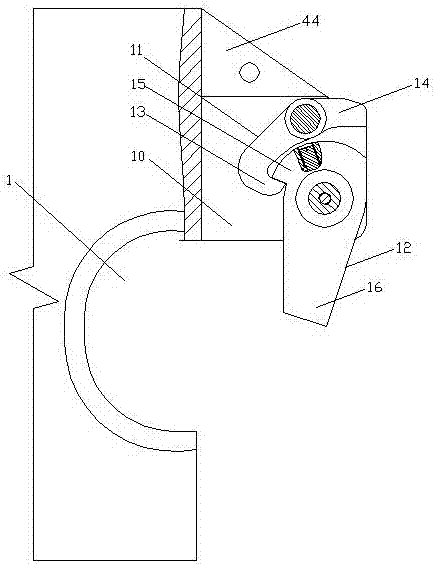

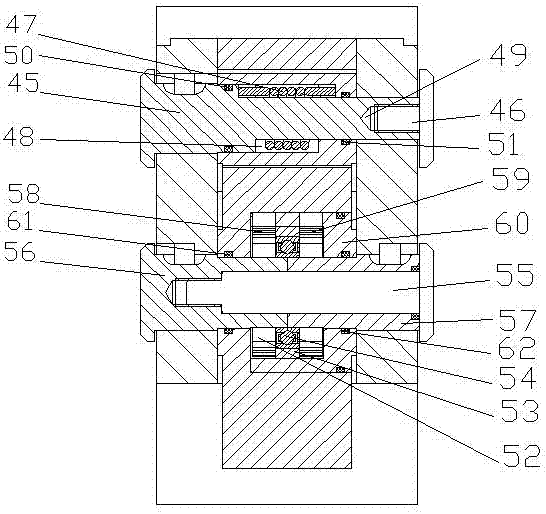

Disengagement prevention and single suspension ring prevention lifting system

ActiveCN106812480AAvoid liftingLifting system provides correct lifting preventionDrilling rodsDrilling casingsEngineeringOil drilling

The invention discloses a disengagement prevention and single suspension ring prevention lifting system, and belongs to the field of oil drilling equipment. The system comprises a disengagement prevention component, the disengagement prevention component comprises a stop block and a lock block, the stop block is in locked connection with the lock block, a sensing component is arranged on the stop block, and a trigger block is arranged on the inner wall of a lower notch; the system further comprises a single suspension prevention component and a disengagement prevention mechanism, the single suspension prevention component comprises a controller, the controller is in wireless electric connection with the sensing component, the disengagement prevention mechanism comprises a locking block and a baffle block, the locking block is in locking connection with the baffle block, the locking block comprises a latch hook portion and a stress portion, the baffle block performs pendulum motion around a rotating shaft, the baffle block swings clockwise and is locked with a latch hook portion of the locking block, the baffle block swing anticlockwise and is unlocked with the locking block, the baffle block comprises a locking portion and a disengagement prevention portion, the locking portion is located inside the upper notch of a suspension lug, and the disengagement prevention portion is located inside a lug hole of the suspension lug. A suspension ring can be firmly blocked into the lug hole, and the using stability of the whole lifting system is ensured; lifting of the single suspension ring can be avoided, and potential safety hazards are eradicated.

Owner:CHENGDU ZHUOXIN IND

Preparation method of solar micro battery on basis of directional carbon nano tube

InactiveCN101667611BSimple structureImprove long-term use stabilityFinal product manufactureSemiconductor devicesNon symmetricMethanoplasmatales

The invention relates to a preparation method of a solar micro battery on the basis of a directional carbon nano tube in the technical field of solar batteries, comprising: dispersing the carbon nano tube into an organic solvent by ultrasound to form stably dispersed carbon nano tube suspension liquid; making two asymmetry metal electrode couple respectively with high-power function and low-powerfunction at a substrate by adopting lithography; applying alternating bias voltage to the asymmetry metal electrode couple, dripping the carbon nano tube suspension liquid on the two electrodes so asto lead the carbon nano tube to from the directional carbon nano tube between the asymmetry electrodes under the action of dimensional electrophoresis force; and adopting high-current selective burnout method or methane plasma selectivity etching method to remove metallic carbon nano tube in the directional carbon nano tube, thus obtaining the solar micro battery. The micro battery is simple in structure and high in stability for long-term use, and can generate high open circuit voltage and efficiency.

Owner:SHANGHAI JIAO TONG UNIV

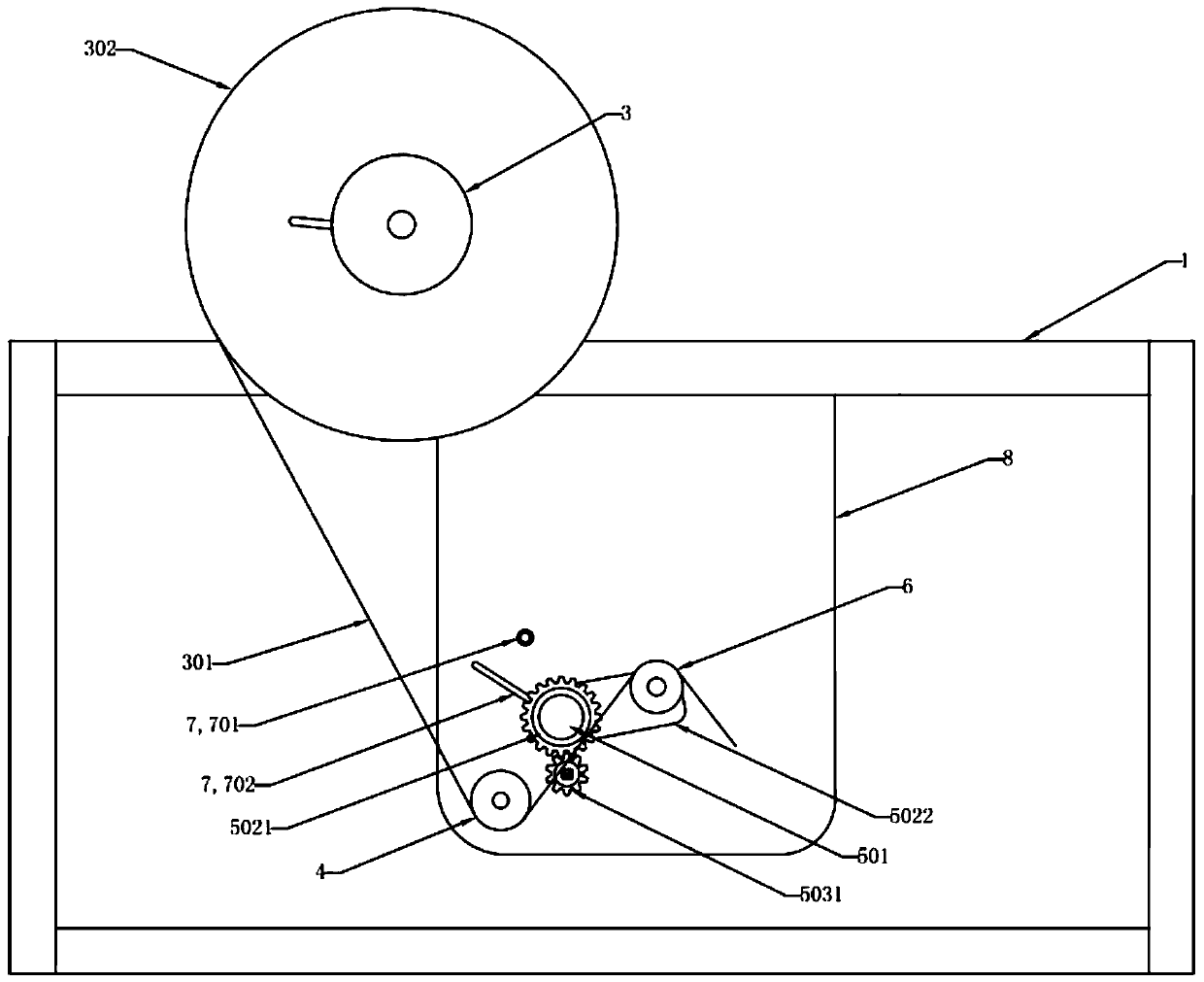

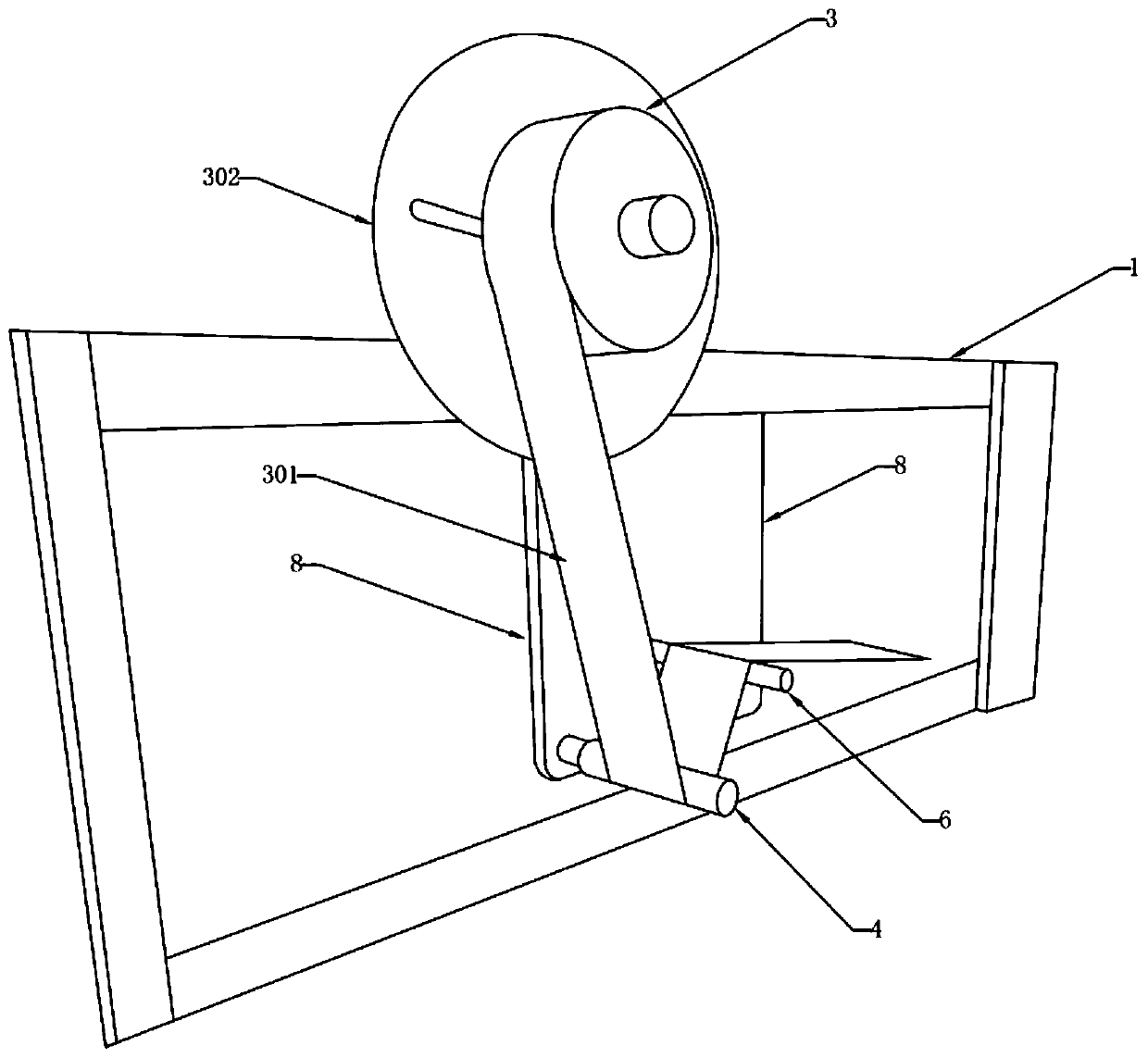

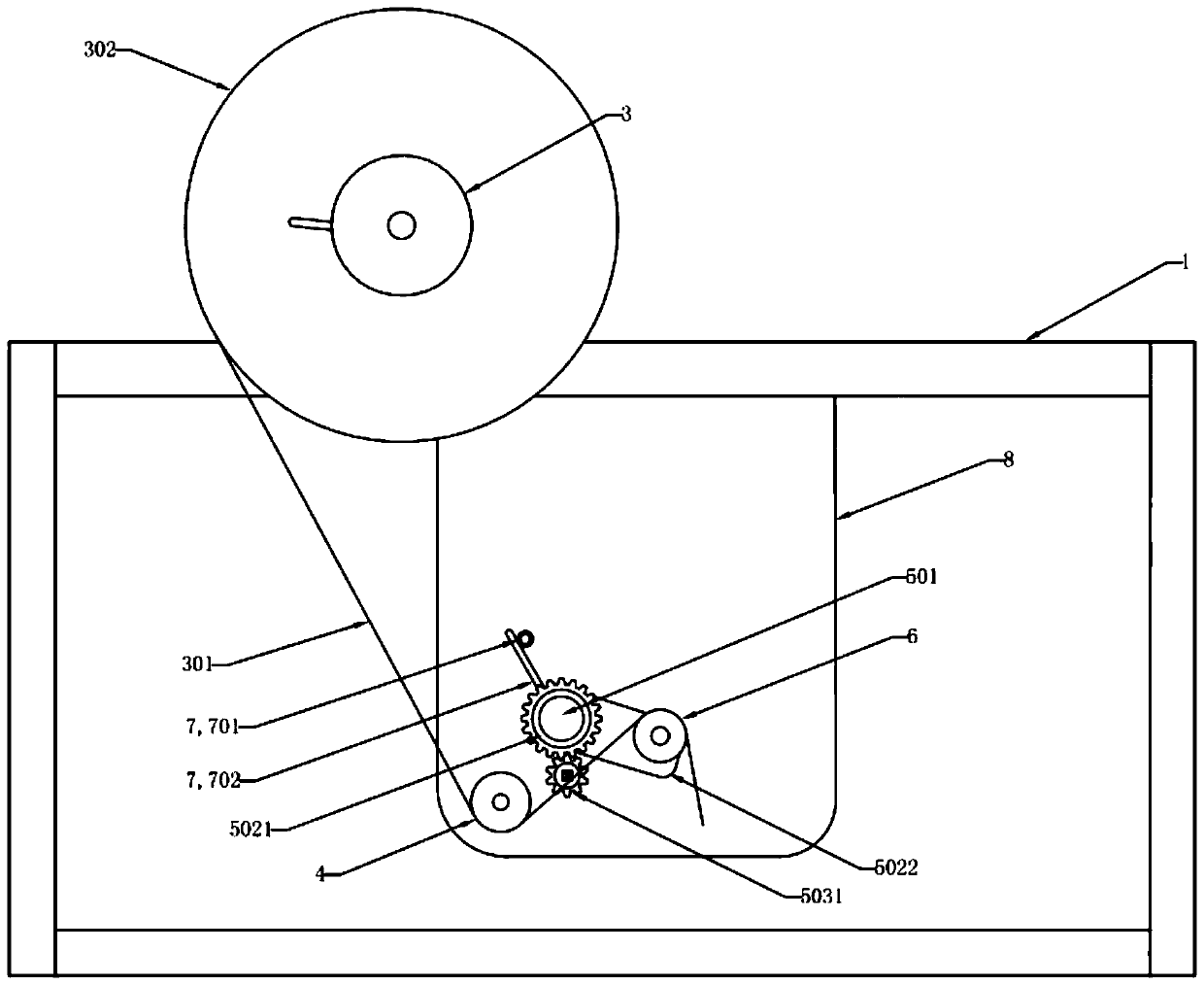

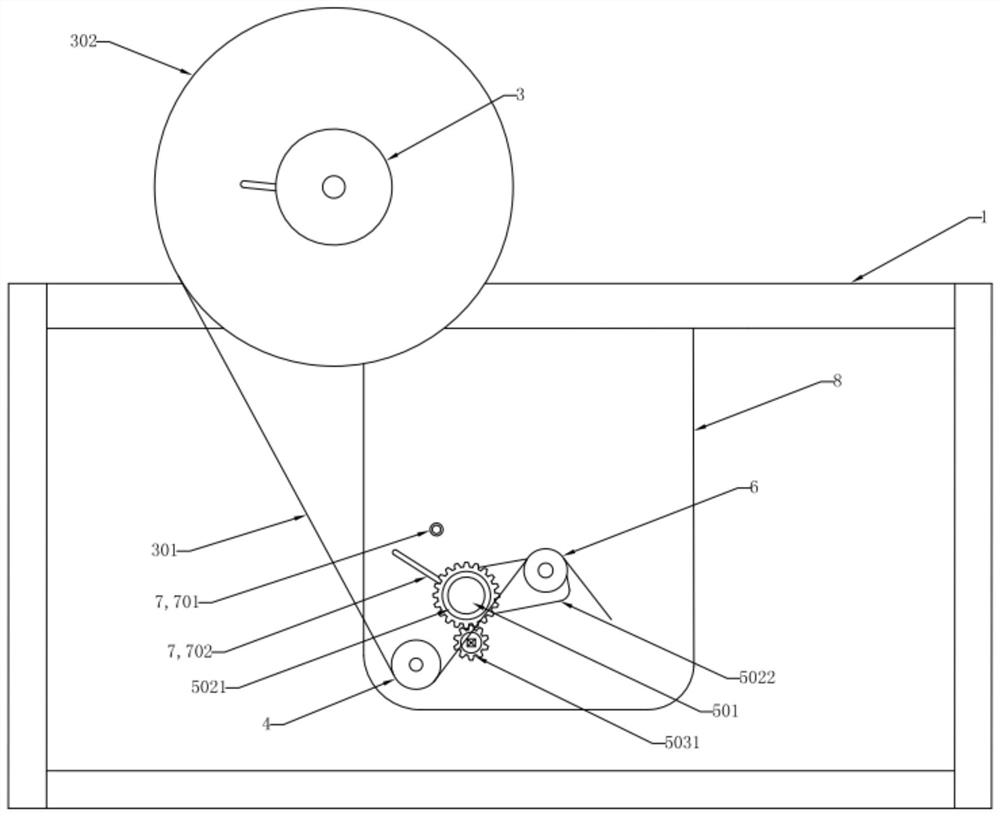

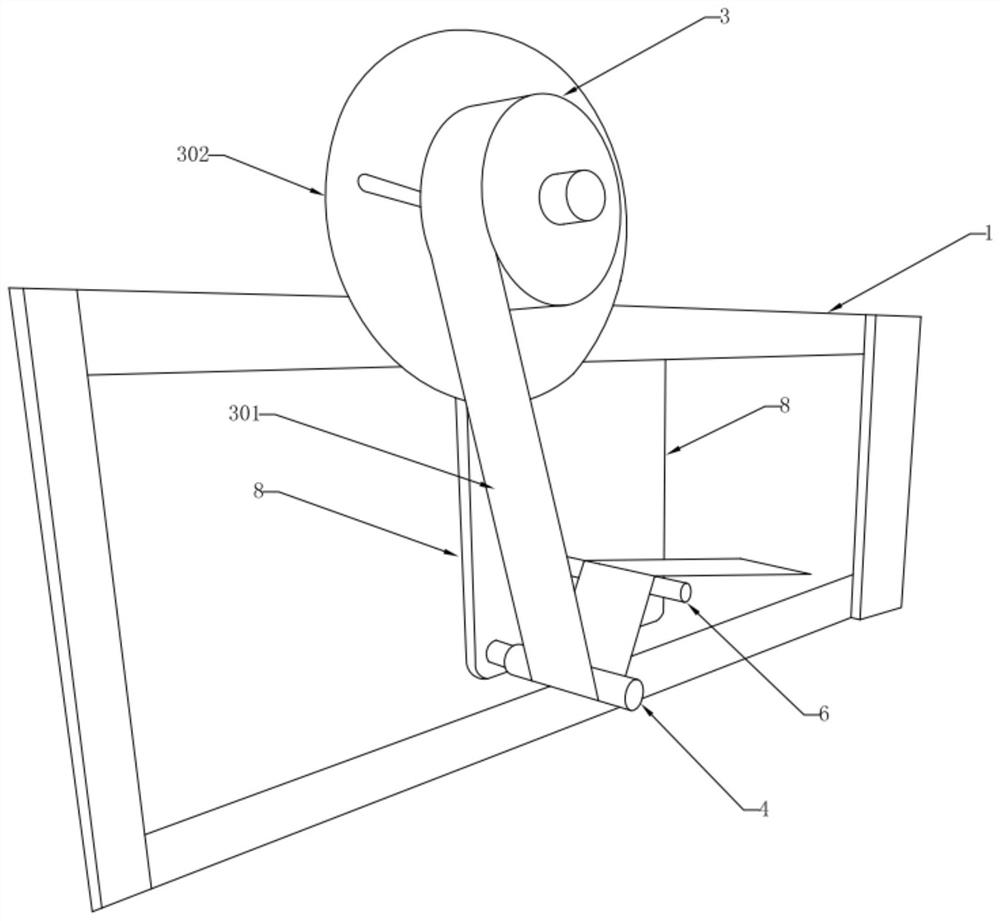

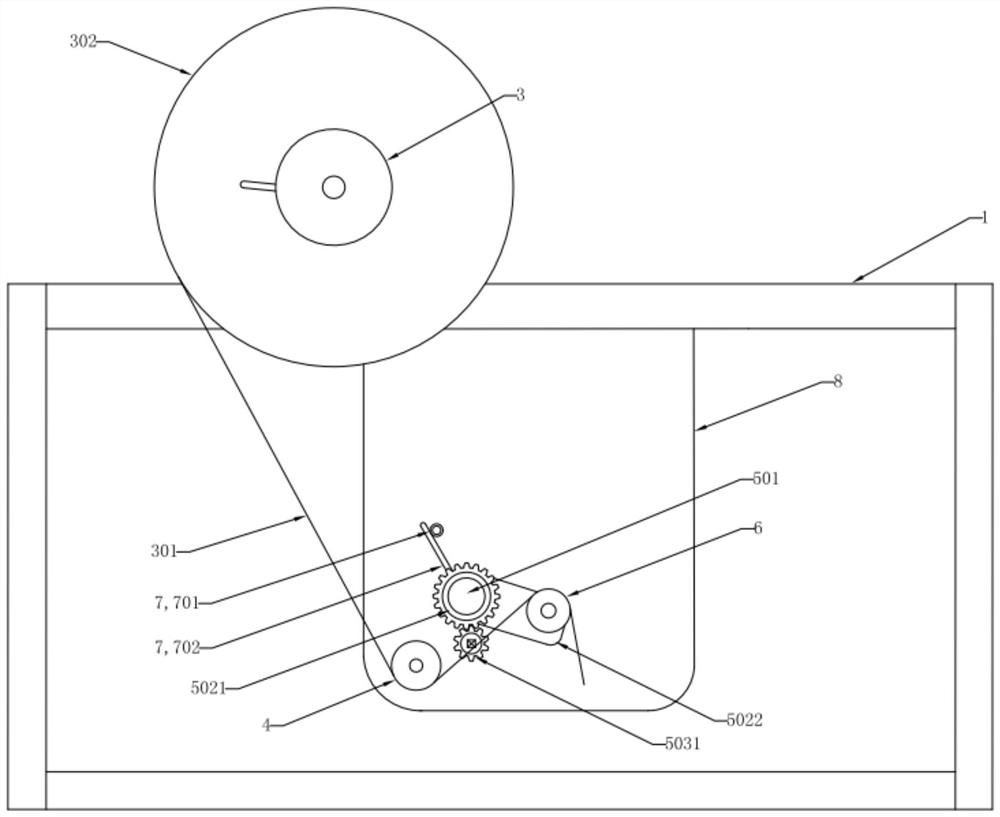

Automatic continuous packaging machine

ActiveCN110356638AStable deliveryReduce tensionWrapping material feeding apparatusPackaging automatic controlFailure rateElectric machinery

The invention provides an automatic continuous packaging machine which comprises a frame, a first driving motor, a paper winding cylinder, a static roller, a power unit, a movable roller and a position sensor; the movable roller, the static roller and the paper winding cylinder are arranged at intervals; and the movable roller has a first limit position and a second limit position in the moving direction of the movable roller, the first driving motor is in a starting state when the movable roller is in the first limit position, a belt body extends out of the paper winding cylinder and is conveyed, and the first driving motor is in a stopping state when the movable roller is in the second limit position. The belt body conveying speed of the packaging machine can be adjusted according to theaction speed of the driving motor and the movable roller, the tension borne by the belt body in the packaging process is small and relatively constant, the belt body can be conveyed smoothly withoutbecoming tighter and tighter in the conveying process, the failure rate is low, and manual intervention is not needed.

Owner:QINGDAO HAINUO BIOLOGICAL ENG

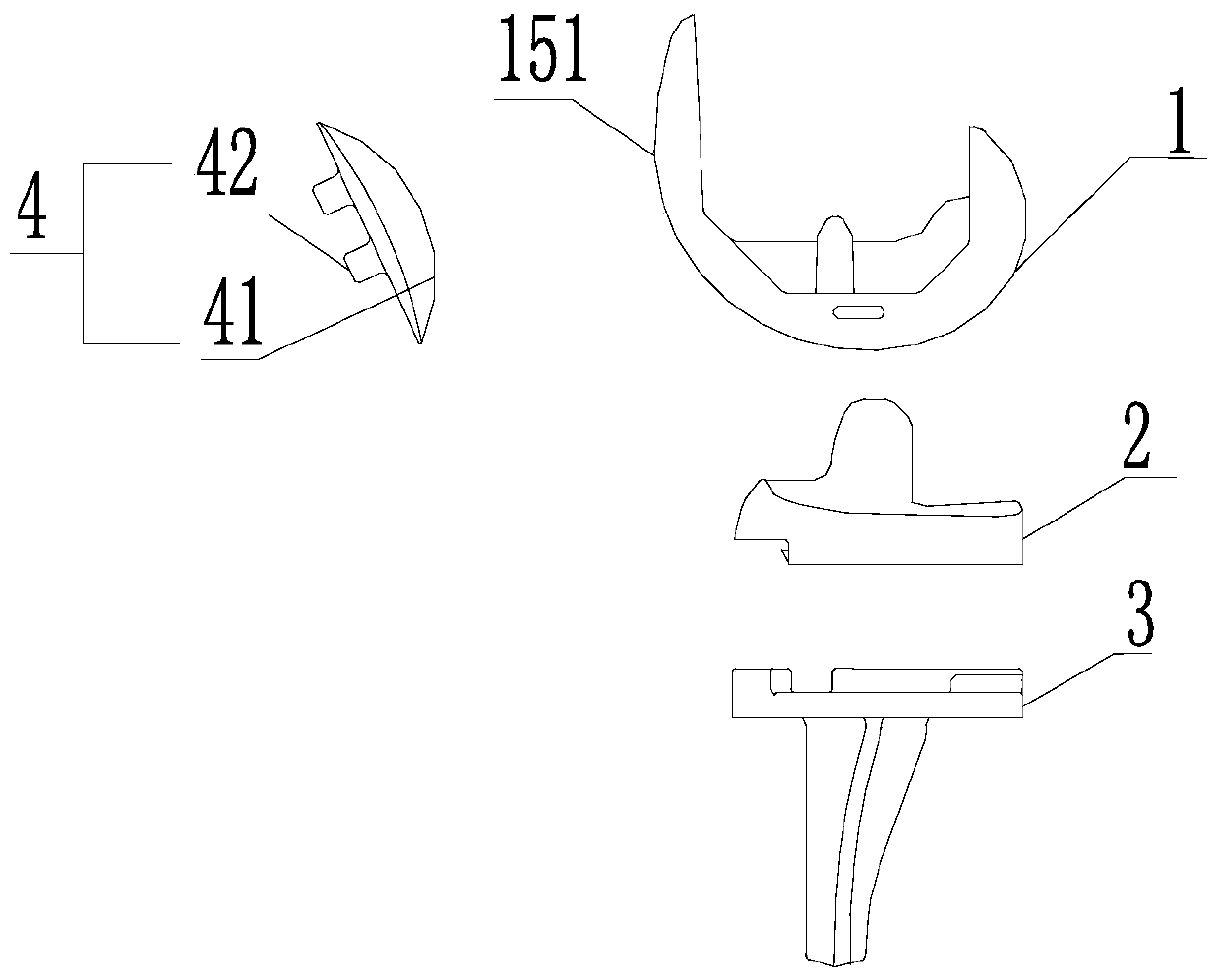

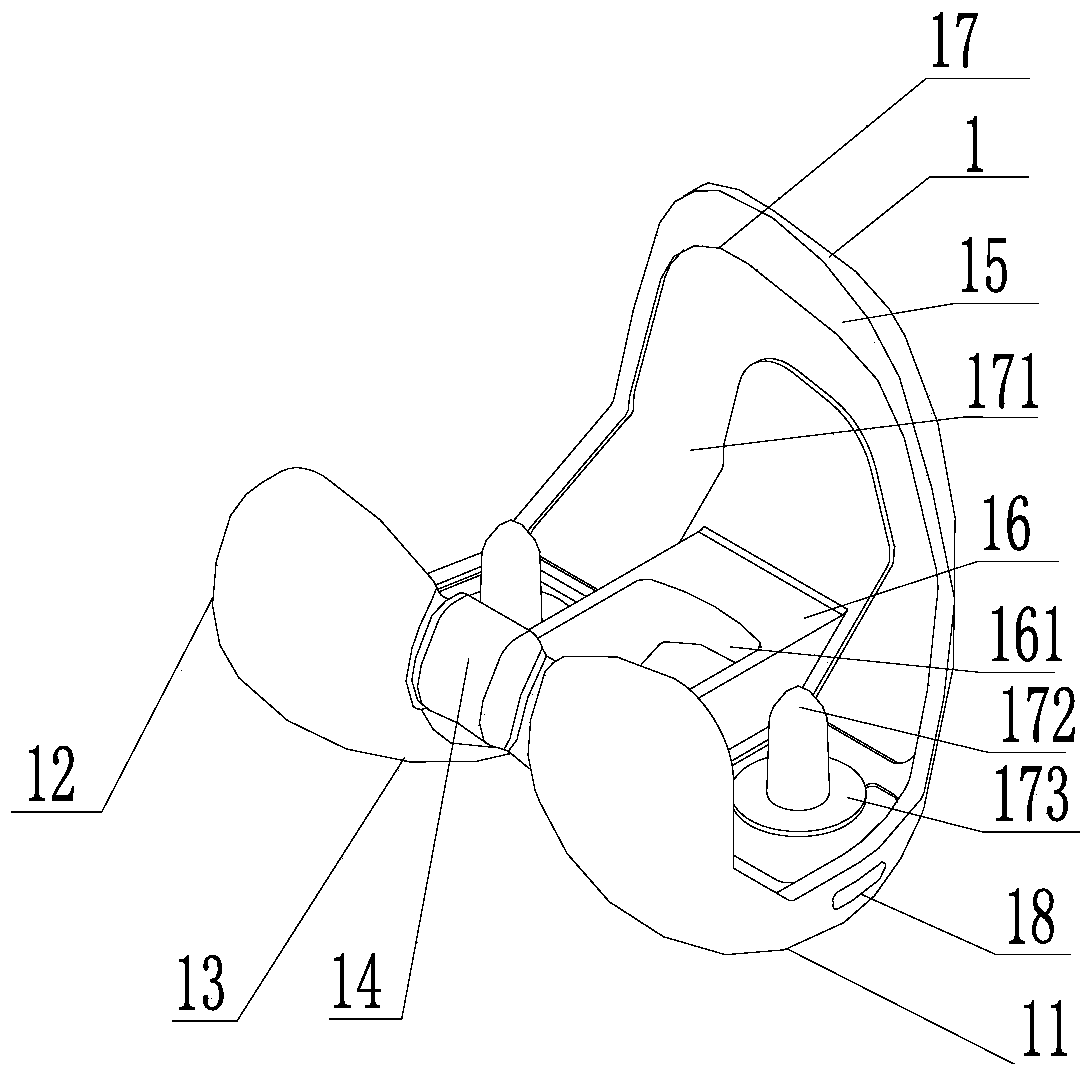

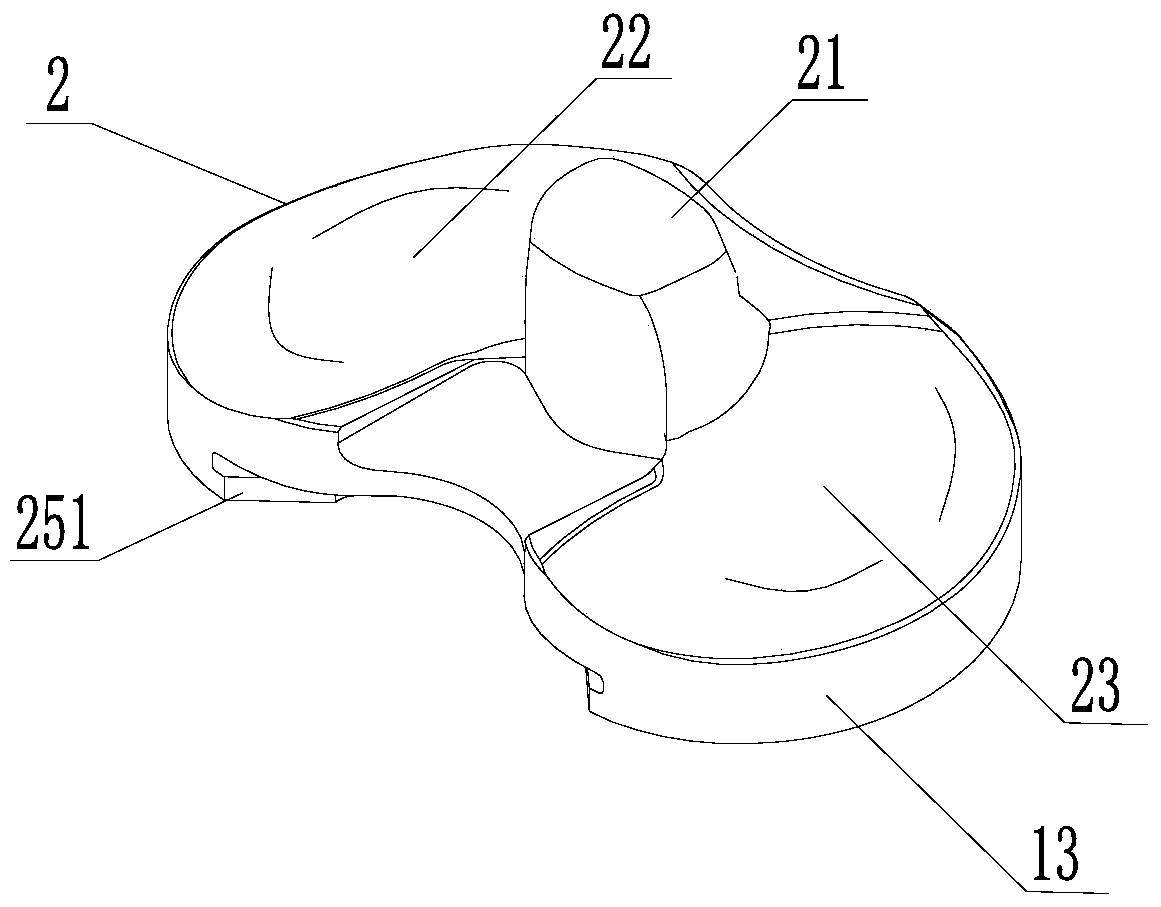

A total knee replacement prosthesis

ActiveCN105030384BImprove stabilityImprove long-term use stabilityJoint implantsKnee jointsArticular surfacesArticular surface

The invention discloses a total knee joint replacement prosthesis, which comprises femoral condyle, tibial support, tibial pad and patella. Position column and glenoid, the glenoid defines the shape of the glenoid surface to match the articular surface of the femoral condyle, the lower end surface of the tibial pad is formed with a first groove and a second groove, and the tibial tray includes a support plate with a fixing member, The upper surface of the support plate has a first pillar and a second pillar locked with the tibial pad, and the patella includes a patella articular surface and a patella fixing post. The total knee replacement prosthesis of the present invention has good initial stability and long-term use stability, improves biocompatibility, is beneficial to bone metabolism, improves tibial support anti-subsidence, anti-rotational resistance and long-term use Stability, further improving the bonding force of the tibial support and the tibial pad, further prolonging the service life of the knee joint.

Owner:北京威高亚华人工关节开发有限公司

Self temperature limiting heat tracing strip of PTC (positive temperature coefficient) high polymer conductive composite material and preparation method thereof

InactiveCN102573154BImprove wettabilityGood dispersionHeating element shapesHeating element materialsPositive temperatureTemperature coefficient

The invention discloses a self temperature limiting heat tracing strip of a PTC (positive temperature coefficient) high polymer conductive composite material, which comprises a flat strip that comprises a polyethylene PTC conductive complex layer. Two conductive core wires are extrusion coated inside the polyethylene PTC conductive complex layer. A polyethylene insulating layer, a shielding layer and a polyethylene reinforced protective layer closed in periphery are arranged orderly outside the polyethylene PTC conductive complex layer from inside to outside. The invention further discloses a preparation method of the self temperature limiting heat tracing strip, which comprises the steps of preparing the polyethylene PTC conductive complex layer; extrusion coating the two conductive core wires; and arranging the polyethylene insulating layer, the shielding layer and the polyethylene reinforced protective layer closed in periphery orderly outside the polyethylene PTC conductive layer from inside to outside. The self temperature limiting heat tracing strip provided by the invention will not generate bubbles, and is stable in electrothermal performance, safe and reliable. The preparation method provided by the invention has simple process flows and low cost, and is easy to realize.

Owner:XIAN GAIWO THERMAL ENERGY TECH

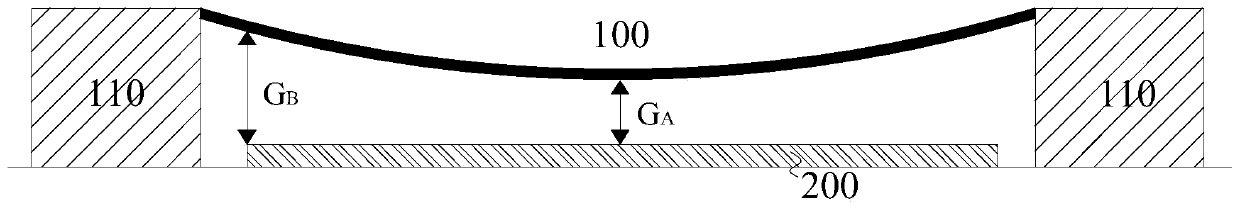

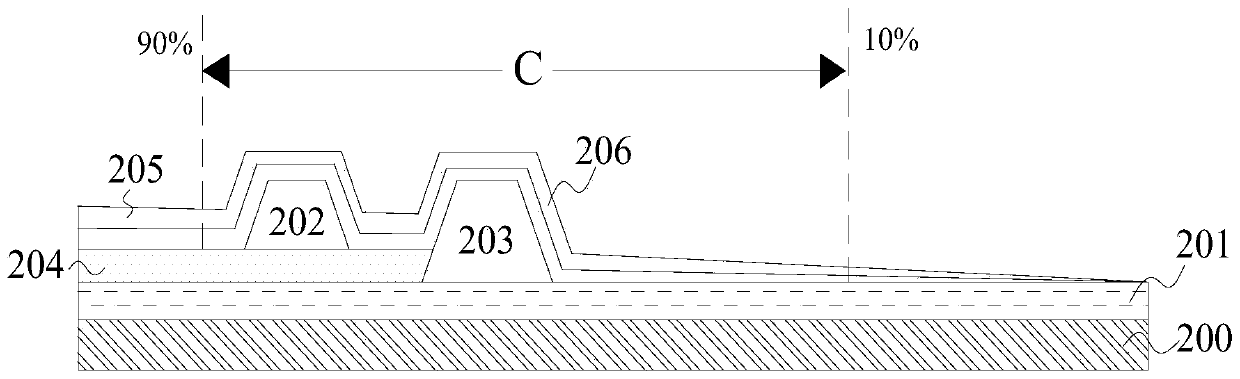

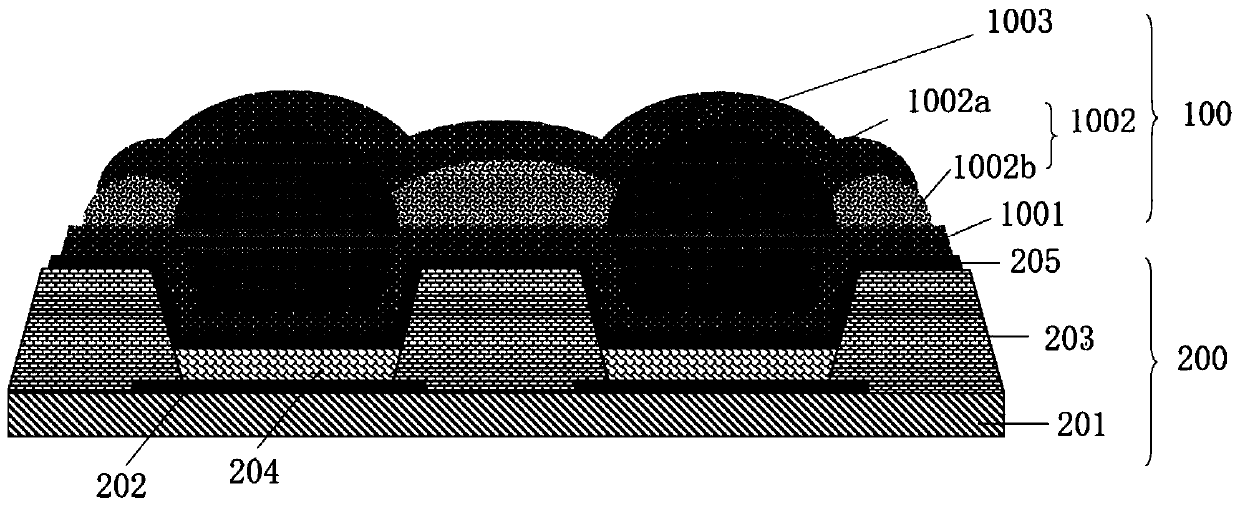

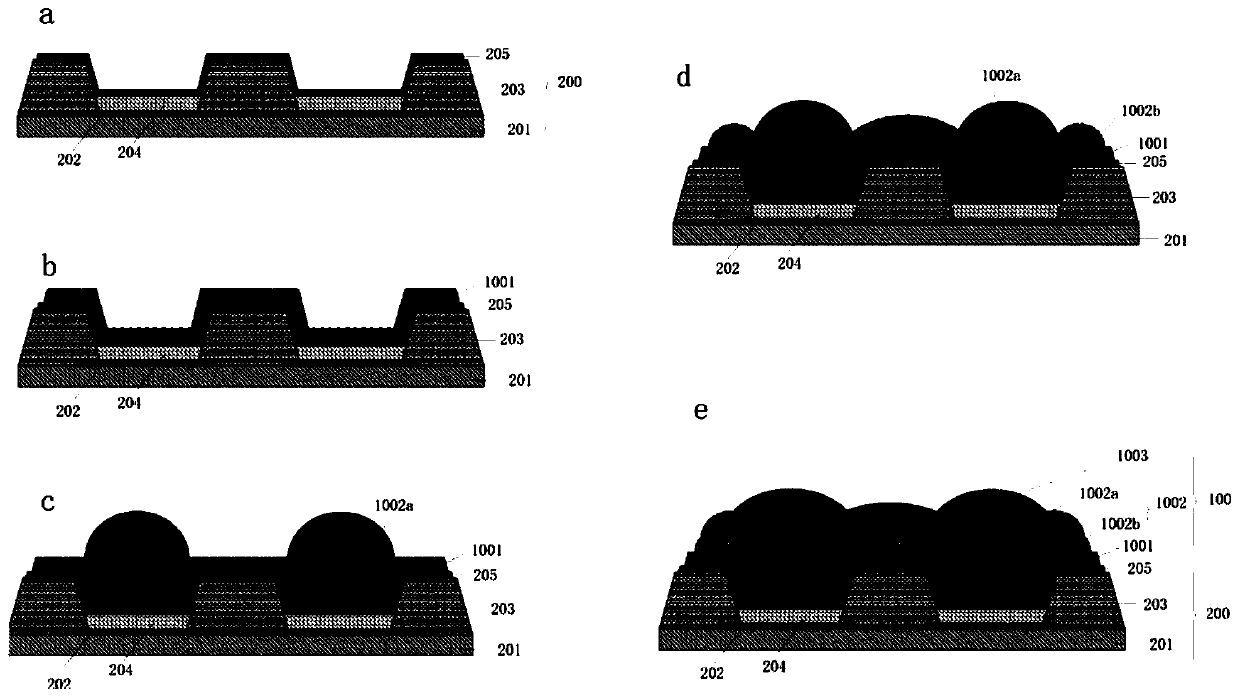

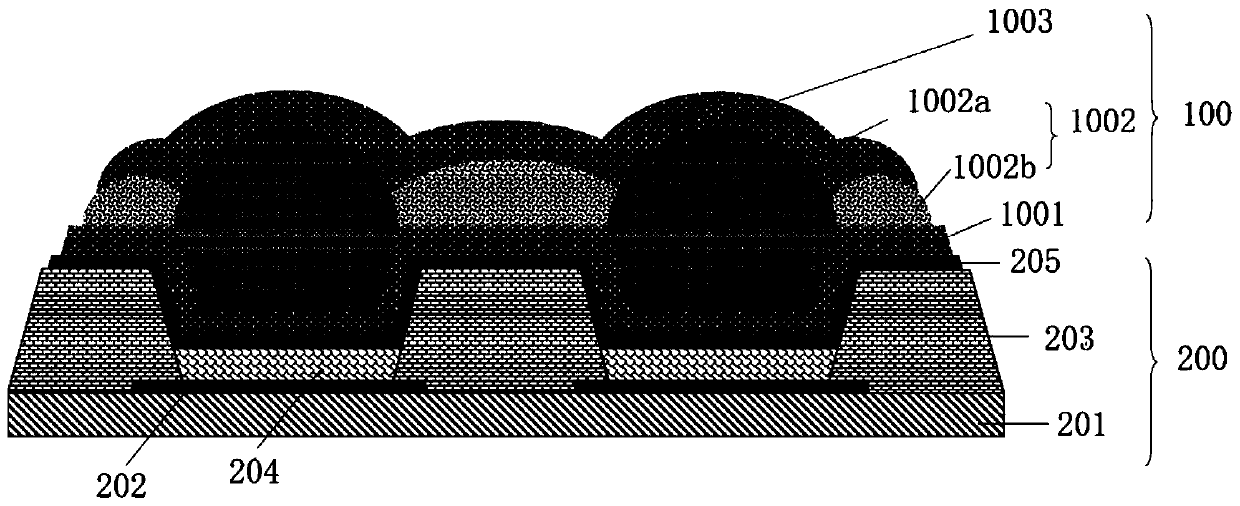

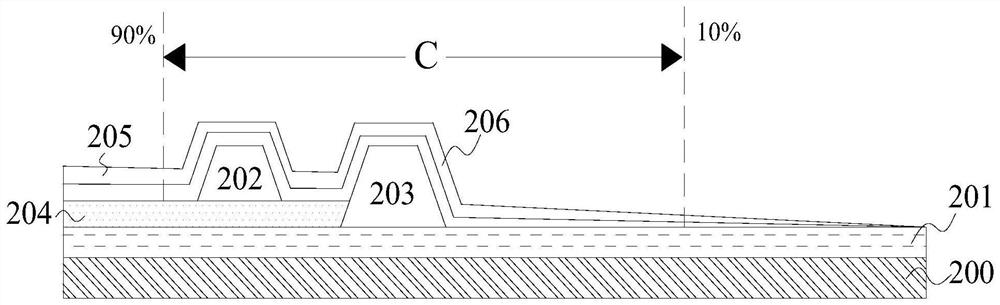

Packaging structure and preparation method thereof, and display panel

ActiveCN111180604APrevent the expansion of the failure zoneImprove packaging effectSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsEngineering

The invention relates to a packaging structure and a preparation method thereof, and a display panel. The packaging structure is used for packaging a light-emitting device, the light-emitting device comprises a pixel area used for arranging a light-emitting unit and a non-pixel area surrounding the pixel area, and the packaging structure comprises a first inorganic barrier layer, a buffer layer and a second inorganic barrier layer which are arranged in a stacked manner; the buffer layer comprises a plurality of organic buffer units, and each organic buffer unit is arranged in the pixel area and is independently arranged corresponding to one light-emitting unit. According to the display packaging structure, each sub-pixel can be provided with an independent buffer structure, water, oxygen and the like can be prevented from diffusing to the adjacent sub-pixels, a failure area is further prevented from being enlarged, and the packaging effect and the long-term use stability of the panel are improved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Processing method for wooden handicraft

InactiveCN111703246AAnti-corrosionAnti-crackPolishing machinesDecorative surface effectsVarnishCarving

The invention relates to the technical field of wall plates, in particular to a processing method for wooden handicraft. According to the processing method for the wooden handicraft, high quality woodwhich is free from pests and diseases and not easy to crack is adopted and is cut into at least two groups of raw materials; each group of the raw materials comprises four sections of timbers with the same length, width and height; and the timbers are ground, subjected to pattern carving, polished, under-painted with seal coat, sprayed with primer coat for more than two times, sprayed with colored varnish, and finally, packaged to form the handicraft. The effects of preventing corrosion, resisting crack, resisting deformation, and improving the long-term service stability can be achieved; twogroups of the handicraft form a pair of handicraft, and each group of the handicraft formed by one section or splicing four sections of timbers; and therefore, the purpose of combining the essence ofnational customs and culture is achieved.

Owner:武冈市柴旺财木业有限公司

a detachment mechanism

ActiveCN106968617BGuaranteed anti-off stabilityReduce the chance of accidental touchDrilling rodsDrilling casingsEngineeringClockwise

The invention discloses an anti-drop mechanism and belongs to the technical field of petroleum drilling equipment. The anti-drop mechanism comprises a check block and further comprises a lock-up block. The lock-up block is connected with the check block in a lock-up mode. The lock-up block comprises a lock hook part and a force bearing part. The check block comprises a lock-up part and an anti-drop part. The lock-up part is located in a lifting lug upper notch. The anti-drop part is located in a lifting lug hole. The check block makes pendulum-type movement and swings clockwise to be locked with the lock hook part of the lock-up block, and accordingly the lock hook part is in a pressed state; and the check block swings anticlockwise to be unlocked with the lock-up block, and accordingly the lock hook part is in an uplift state. The check block is connected with the lock-up block in a lock-up mode, so that locking is reliable, and the stability of the check block is greatly guaranteed. Due to the fact that the lock-up block is located in the lifting lug upper notch, the lock-up block is not exposed on the outer side of an elevator, so that wrong touching of the lock-up block can be effectively avoided, safe reliability in the operation process is greatly improved, and the safety accident is avoided.

Owner:CHENGDU ZHUOXIN IND

An anti-off and anti-single ring hoisting system

ActiveCN106812480BGuaranteed sensitivityAvoid liftingDrilling rodsDrilling casingsEngineeringOil drilling

The invention discloses a disengagement prevention and single suspension ring prevention lifting system, and belongs to the field of oil drilling equipment. The system comprises a disengagement prevention component, the disengagement prevention component comprises a stop block and a lock block, the stop block is in locked connection with the lock block, a sensing component is arranged on the stop block, and a trigger block is arranged on the inner wall of a lower notch; the system further comprises a single suspension prevention component and a disengagement prevention mechanism, the single suspension prevention component comprises a controller, the controller is in wireless electric connection with the sensing component, the disengagement prevention mechanism comprises a locking block and a baffle block, the locking block is in locking connection with the baffle block, the locking block comprises a latch hook portion and a stress portion, the baffle block performs pendulum motion around a rotating shaft, the baffle block swings clockwise and is locked with a latch hook portion of the locking block, the baffle block swing anticlockwise and is unlocked with the locking block, the baffle block comprises a locking portion and a disengagement prevention portion, the locking portion is located inside the upper notch of a suspension lug, and the disengagement prevention portion is located inside a lug hole of the suspension lug. A suspension ring can be firmly blocked into the lug hole, and the using stability of the whole lifting system is ensured; lifting of the single suspension ring can be avoided, and potential safety hazards are eradicated.

Owner:CHENGDU ZHUOXIN IND

Metal reticle, display panel and display device

ActiveCN110838565BImprove manufacturing yieldImprove thickness uniformitySolid-state devicesVacuum evaporation coatingDisplay deviceEngineering

The present invention proposes a metal mask, a display panel and a display device. The metal mask includes an opening area and a peripheral area, the peripheral area is arranged around the opening area, and the peripheral area is provided with a first half notch, and the first half notch is arranged around the opening area. The metal reticle proposed by the present invention can effectively improve the sag of the metal reticle and reduce the tension of the metal reticle by introducing the first half-grooves arranged around the opening area in the peripheral area, thereby improving the use of the metal reticle. The thickness uniformity of the inorganic encapsulation layer formed by the reticle at different positions further increases the production yield of the display panel.

Owner:BOE TECH GRP CO LTD +1

A lifting method with anti-off and anti-single ring

ActiveCN106968618BGuaranteed sensitivityAvoid liftingDrilling rodsDrilling casingsIndustrial engineering

The invention discloses a method for preventing drop and hoisting of a single hanging ring. The method comprises the steps that a, a drop preventing mechanism of a system for preventing drop and hoisting of the single hanging ring is opened and made to be in an unlocking state; b, when one of the hanging rings is mounted in the position, on one side of an elevator, of a lug hole of a lifting lug, an induction part of a drop preventing part sends a signal, after receiving the signal, a controller forbids moving of a runner wagon, the runner wagon is in a stop state, and after the hanging ring enters the lug hole, the drop preventing mechanism is in a locking state, and the hanging ring is blocked in the lug hole; and c, and the other hanging ring is mounted in the position, on the other side of the elevator, inside the lug hole of the lifting lug, the induction part of the drop preventing part sends a signal, and after receiving the signal, the controller allows the runner wagon to move. It can be effectively guaranteed that the two hanging rings both enter the lug hole, so that single hanging ring hoisting is avoided. Through the joint effect of the drop preventing mechanism and the drop preventing part, the hanging rings can be blocked firmly in the lug hole, slipping is avoided, the working stability and reliability of the elevator are improved, and the safety accident is eradicated.

Owner:CHENGDU ZHUOXIN IND

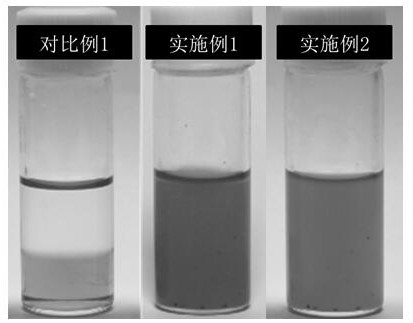

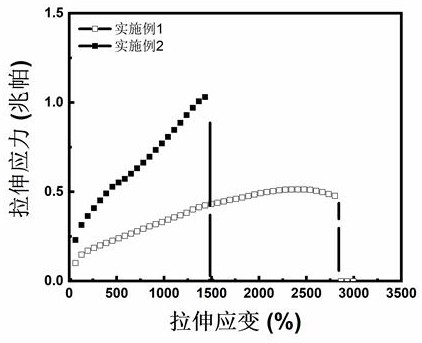

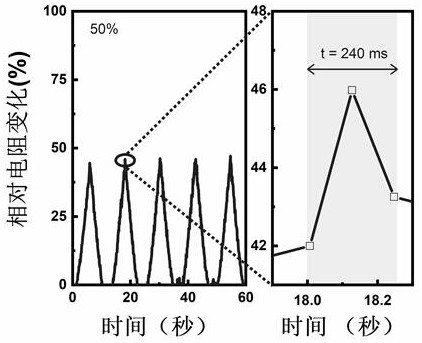

A kind of preparation method and application of ionic liquid conductive elastomer

ActiveCN113416285BWell mixedStable and excellent conductivityDiagnostic recording/measuringSensorsElastomerPolymer science

The invention relates to a preparation method and application of an ionic liquid conductive elastomer. The conductive elastomer first realizes uniform mixing of ionic liquid and butyl acrylate through vinyl silica, and then initiates free radical polymerization by light to obtain . The nano-sized vinyl silica realizes the homogeneous mixing of the polar ionic liquid and the non-polar elastomer butyl acrylate monomer, and the prepared conductive elastomer has excellent conductivity. In addition, the introduction of vinyl silica also builds a cross-linked polymer network, which effectively improves the mechanical properties of the conductive elastomer and enhances the long-term stability of the material.

Owner:DONGHUA UNIV

An automatic continuous packaging machine

ActiveCN110356638BStable deliveryReduce tensionWrapping material feeding apparatusPackaging automatic controlRolling paperControl engineering

The invention provides an automatic continuous packaging machine, which includes a frame, a first driving motor, a paper roll, a static roll, a power unit, a moving roll and a position sensor; the moving roll, the static roll and the roll are all Arranged at intervals, in the moving direction of the moving roller, the moving roller has a first limit position and a second limit position. When the moving roller is at the first limit position, the first driving motor is in the starting state, and the belt is driven from the roll paper The drum is stretched out and conveyed, and when the moving roller is at the second extreme position, the rotation of the first driving motor is in a stopped state. The conveying speed of the belt body of this packaging machine can be adjusted according to the action speed of the driving motor and the moving roller. During the packaging process, the tension on the belt body is relatively small and relatively constant. The rate is low and no human intervention is required.

Owner:QINGDAO HAINUO BIOLOGICAL ENG

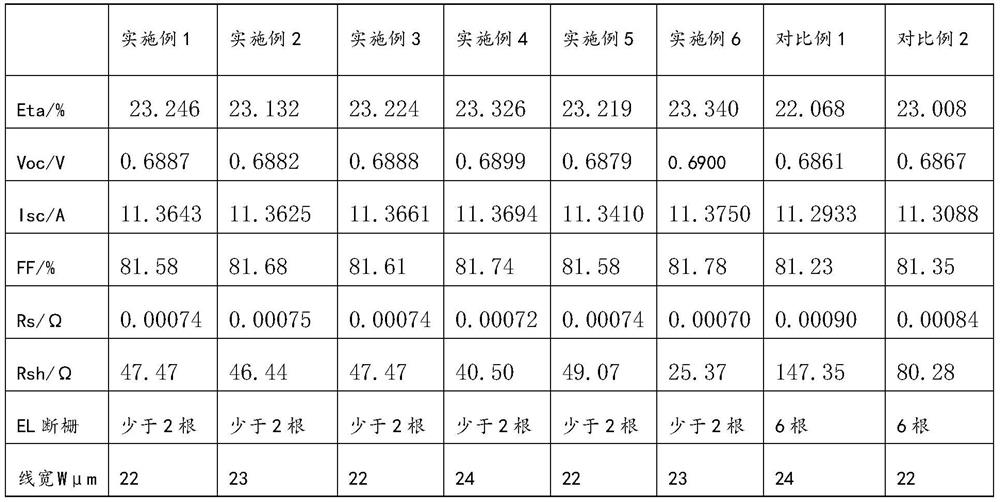

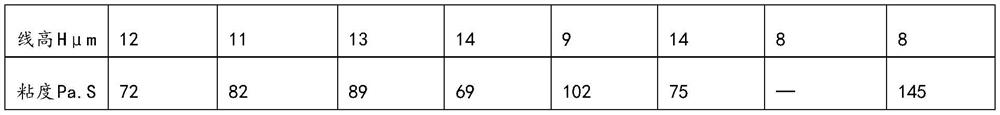

Electrode silver paste for front surface of crystalline silicon solar cell

PendingCN113871056AFully coveredEasy to separateNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteElectrical battery

The invention provides electrode silver paste for the front surface of a crystalline silicon solar cell, the raw material components comprise organic resin, silver powder, glass powder, a solvent and an organic additive, and the preparation method comprises the following steps: resin dissolution, silver powder wrapping, resin shaping, secondary dispersion and silver paste preparation. According to the preparation method of the coated silver powder by firstly dissolving the resin, an obtained positive silver paste system of the silver powder and the resin is wider in selection range of the resin, any resin capable of being dissolved in a solvent can be used for coating the silver powder through the method, and the selection range of the coated resin is greatly widened. And some resins which cannot be well dissolved in a solvent can also be used in an organic system of the slurry, so that the application range of the resins is expanded, and greater possibility is provided for better adaptation to fine line printing.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

Production process and production line for continuous stainless steel coil

ActiveCN101797602BBeautiful appearanceUniform and bright colorProduction lineUltimate tensile strength

Owner:BAC DALIAN

A preparation method of polycrystalline alumina fiber needle-punched liner

The present invention relates to the field of manufacturing methods of fiber liners, in particular to a method for preparing polycrystalline alumina fiber needle-punched liners, which uses PCW long fibers to weave and then dry-forms to obtain needle-punched liners, comprising the following steps (1) Preliminary opening of fibers; (2) Collecting cotton; (3) Carding and laying; (4) Needle punching; (5) High temperature drying; (6) Cutting into the set size to obtain polycrystalline oxidation Aluminum fiber needle-punched liner. In the present invention, PCW long fibers are selected for braiding dry forming without glue. To ensure that the high-temperature filling density and support force remain constant, weaving overlapping long fibers also effectively avoids the possibility of the gasket itself being eroded by the engine exhaust flow. The preparation method of the polycrystalline alumina fiber needle-punched liner provided by the invention fills up the current domestic blank and solves the problem of high cost of imported products.

Owner:江苏腾利特种纤维科技有限公司

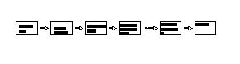

Preparation method of solar microbattery based on random mesh carbon nanotube film

InactiveCN101656278BSimple structureEase of mass productionFinal product manufactureSemiconductor devicesSolar lightMethanoplasmatales

The invention relates to a preparation method of a solar microbattery based on a random mesh carbon nanotube film in the energy field. The random mesh carbon nanotube film is prepared by adopting a self assembly technology; a selective methane plasma etching method or a large-current blowing method is adopted to remove a metallic carbon nanotube to obtain a large-area random mesh semi-conductive carbon nanotube film as a photosensitive material of a solar microbattery; and metals with an asymmetrical work function are respectively used as asymmetrical electrodes of a device to contact with the semi-conductive carbon nanotube and respectively form asymmetrical junctions at both contact ends of the semi-conductive carbon nanotube so as to form a strong internal electric field in the single-wall semi-conductive carbon nanotube and stimulate the separation of a photo-generated electron-hole pair. The preparation process of the solar microbattery is simple and easy to operate and can realize mass production. The solar microbattery has higher photoelectric conversion efficiency during simulating solar light irradiation and has wide application in the field of photovoltaic devices.

Owner:SHANGHAI JIAO TONG UNIV

Anti-drop mechanism

ActiveCN106968617AGuaranteed anti-off stabilityReduce the chance of accidental touchDrilling rodsDrilling casingsEngineeringMechanical engineering

The invention discloses an anti-drop mechanism and belongs to the technical field of petroleum drilling equipment. The anti-drop mechanism comprises a check block and further comprises a lock-up block. The lock-up block is connected with the check block in a lock-up mode. The lock-up block comprises a lock hook part and a force bearing part. The check block comprises a lock-up part and an anti-drop part. The lock-up part is located in a lifting lug upper notch. The anti-drop part is located in a lifting lug hole. The check block makes pendulum-type movement and swings clockwise to be locked with the lock hook part of the lock-up block, and accordingly the lock hook part is in a pressed state; and the check block swings anticlockwise to be unlocked with the lock-up block, and accordingly the lock hook part is in an uplift state. The check block is connected with the lock-up block in a lock-up mode, so that locking is reliable, and the stability of the check block is greatly guaranteed. Due to the fact that the lock-up block is located in the lifting lug upper notch, the lock-up block is not exposed on the outer side of an elevator, so that wrong touching of the lock-up block can be effectively avoided, safe reliability in the operation process is greatly improved, and the safety accident is avoided.

Owner:CHENGDU ZHUOXIN IND

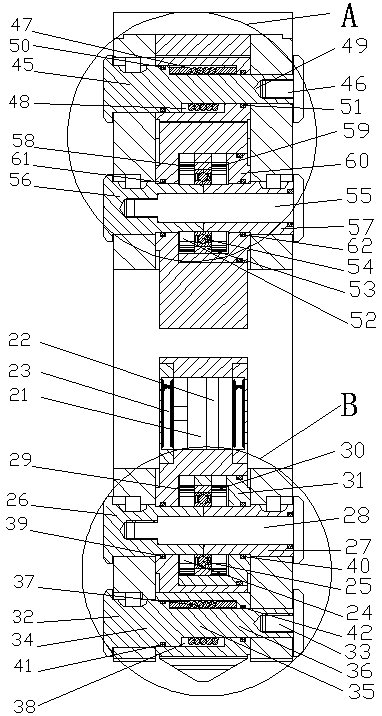

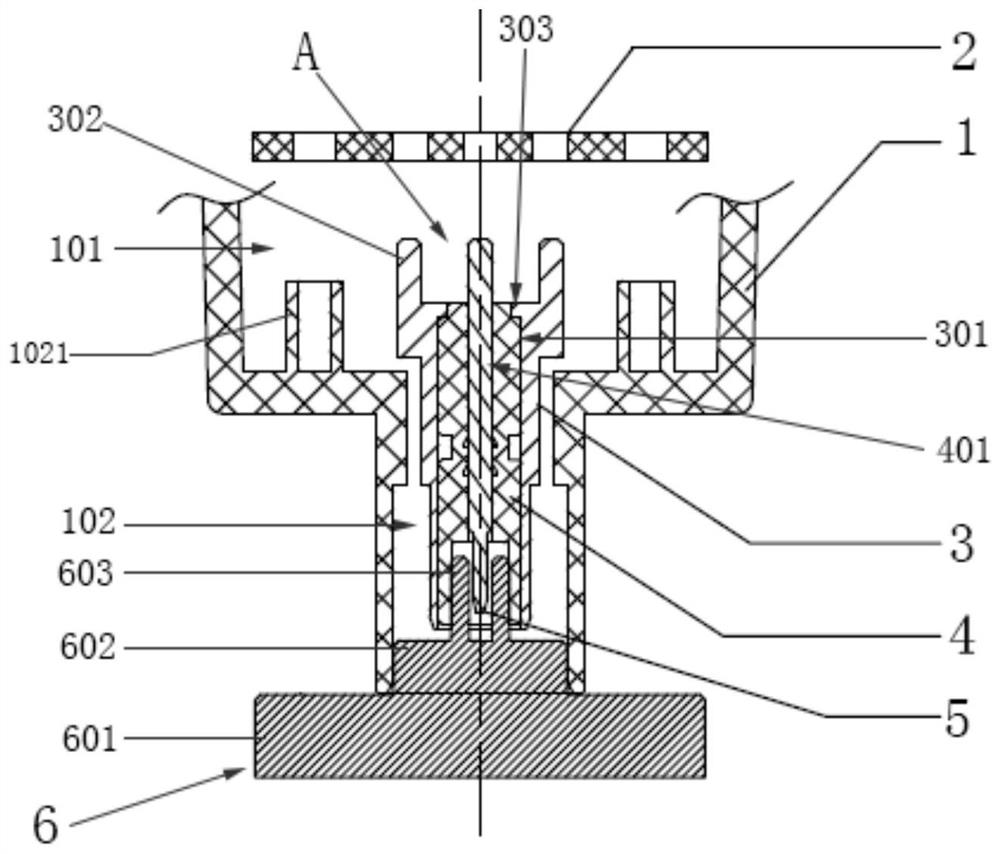

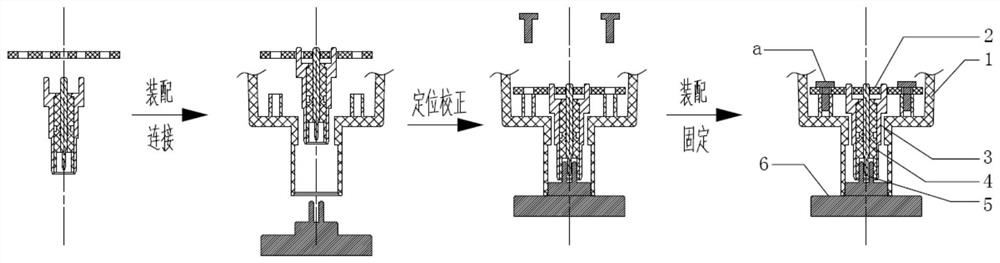

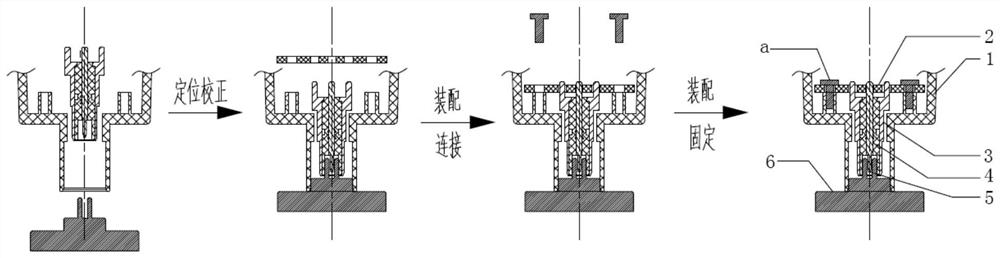

Vehicle-mounted camera module connector including positioning structure and assembly method thereof

ActiveCN110265810BSolve the shortcomings of poor concentricityHigh concentricityVehicle connectorsContact member assembly/disassemblyIn vehicleCamera module

The invention relates to a vehicle-mounted camera module connector including a positioning structure, comprising: a housing (1), including a first cavity (101) and a second cavity (102), used for connecting the vehicle-mounted camera module with a vehicle connection circuit board (2), fixedly supported in the first cavity (101); board end connector (A), through the first cavity (101) and the second cavity (102) , and fixedly connected with the circuit board (2); the positioning structure (6); the positioning structure (6) includes a base (601), a correction table (602) and a correction ring (603); the correction table (602 ) is supported on the base (601) and connected with the second cavity (102) for correcting the concentricity of the shell (1); the correction ring (603) is supported on the correction platform (602) and connected with the plate end The connector (A) is connected at the end far away from the circuit board (2), and is used for correcting the concentricity of the connector (A) at the board end. The invention can make the assembled connector have good concentricity.

Owner:ZHEJIANG SUNNY SMARTLEAD TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com