Automatic continuous packaging machine

A packaging machine and automatic technology, applied in packaging, transport packaging, packaging protection, etc., can solve the problems of small consumption radius, reduce production efficiency, increase production cost, etc., and achieve the effect of smooth transportation, convenient observation and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in combination with specific embodiments.

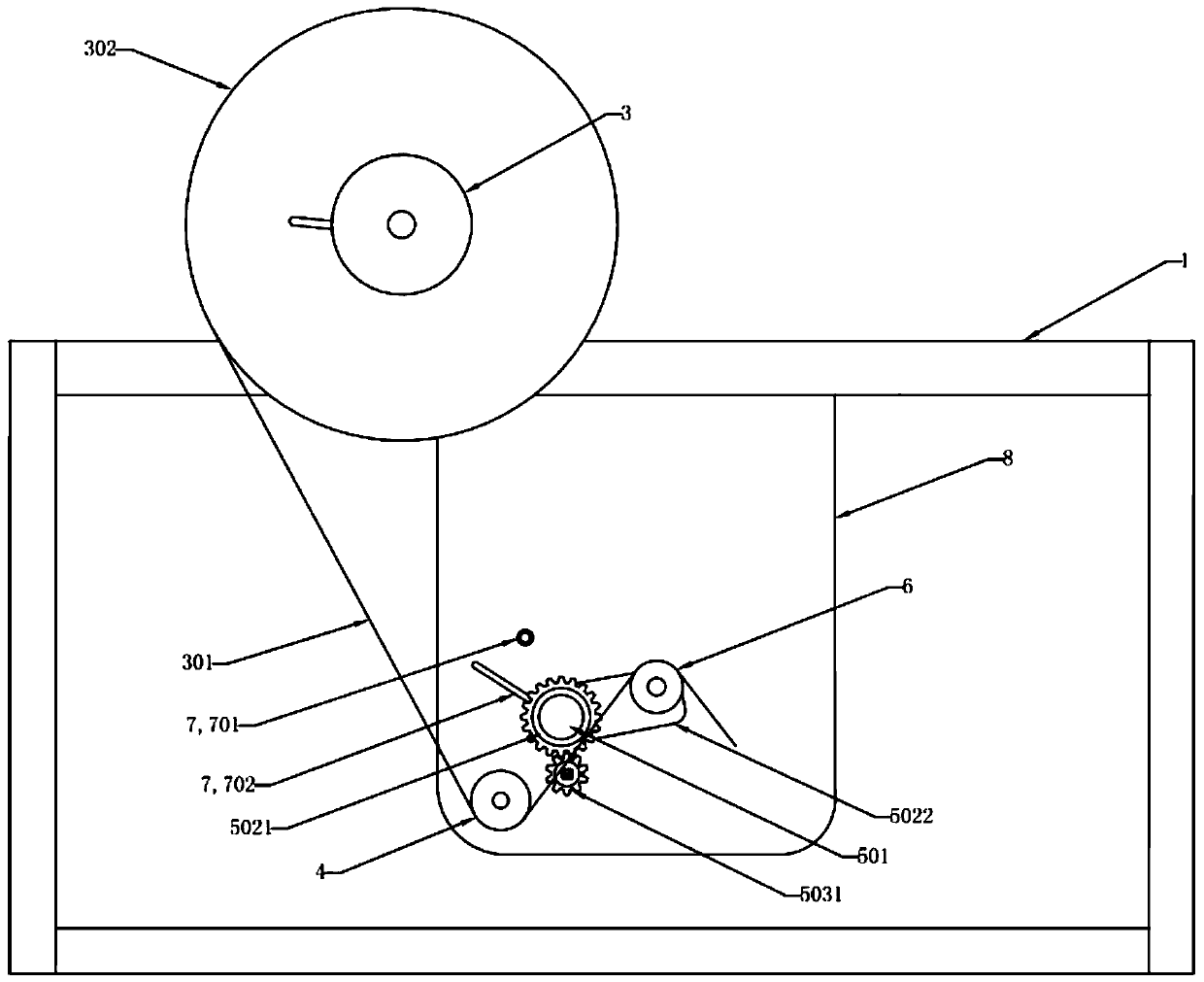

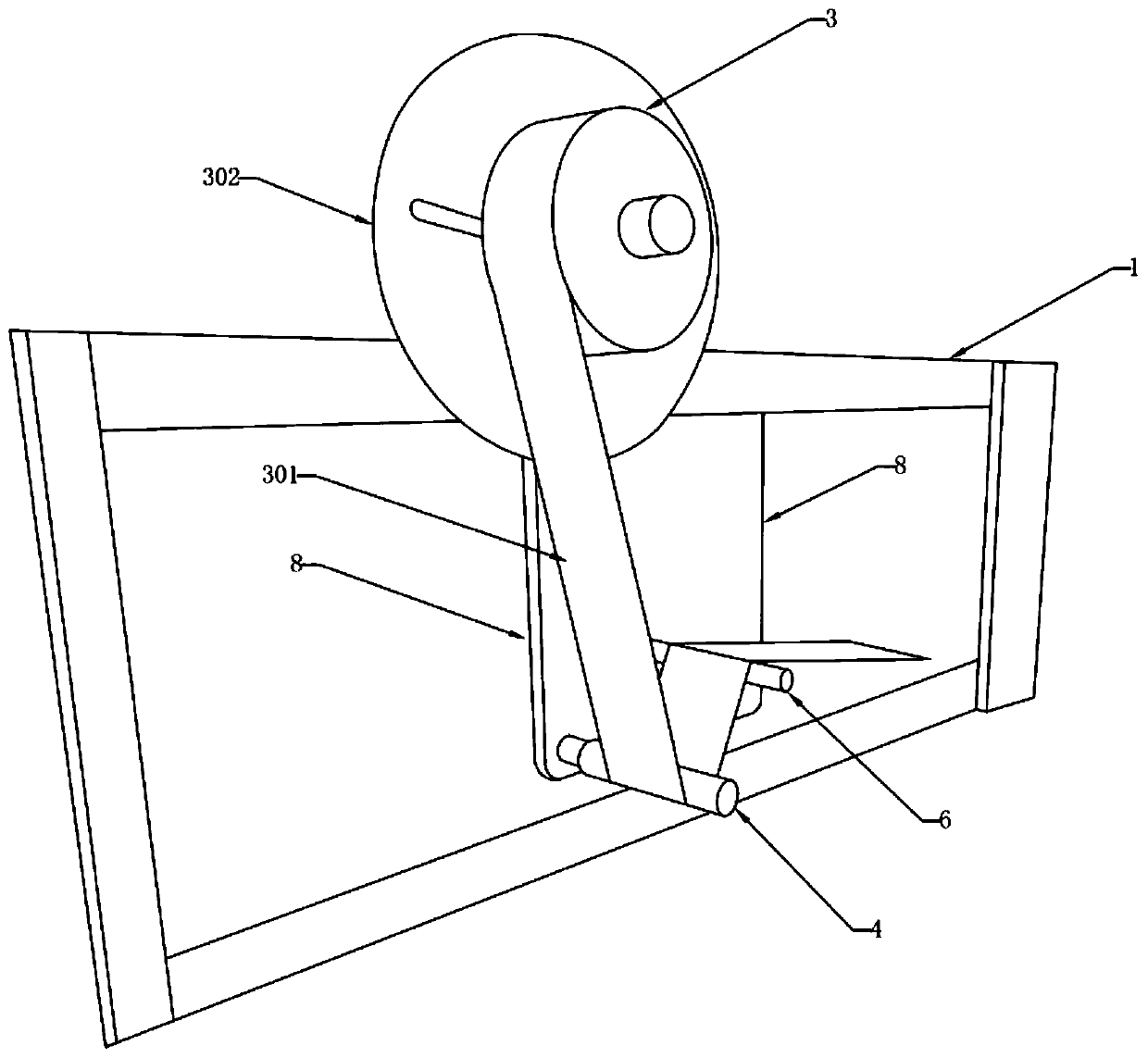

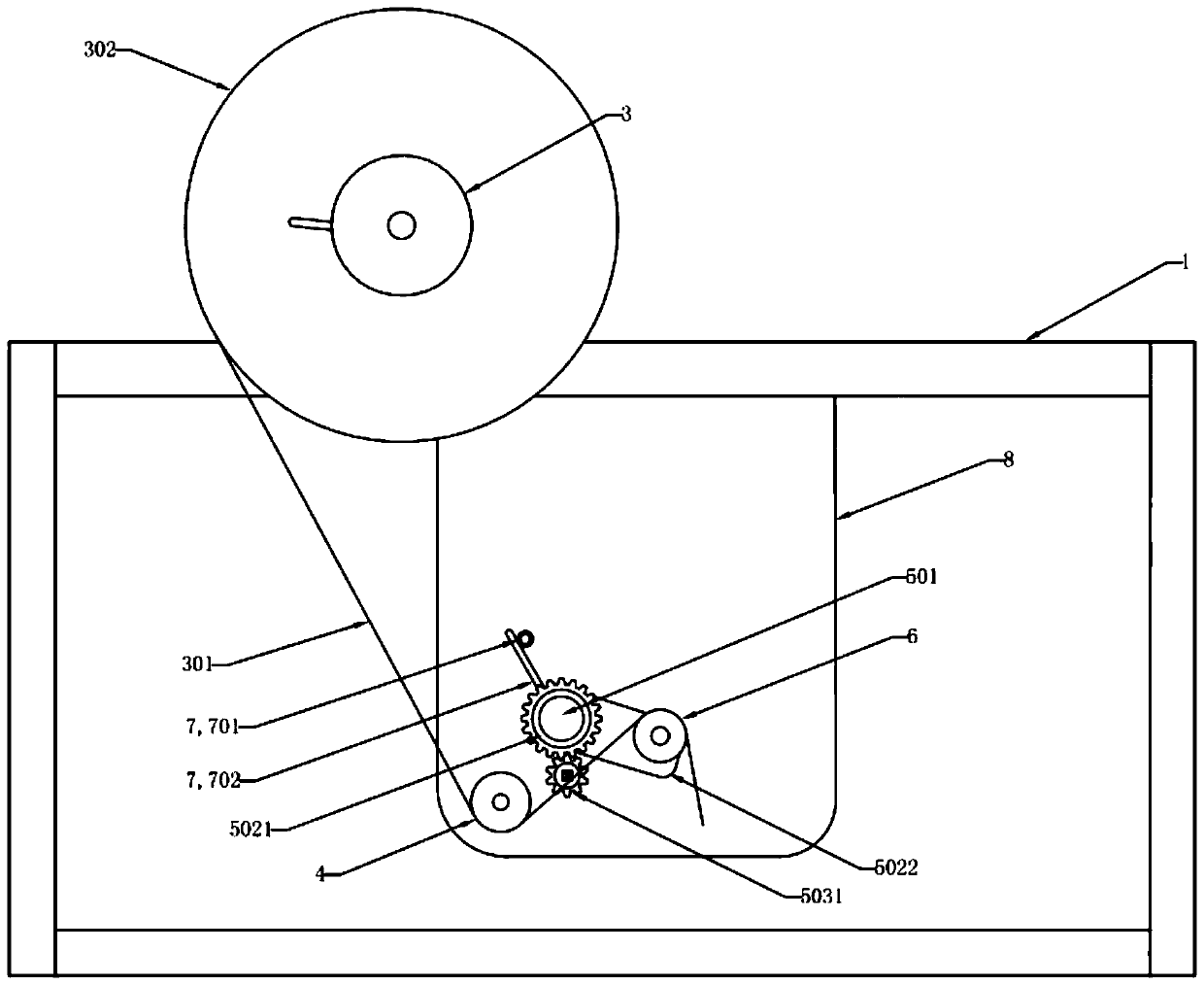

[0044] figure 1 and figure 2 Shown are the structural schematic diagrams of the automatic continuous packaging machine in Embodiment 1 of the present invention under two viewing angles. The automatic continuous packaging machine shown in Embodiment 1 of the present invention includes a frame 1, a first driving motor 2, a paper reel 3, a static roller 4, a power unit 5, a moving roller 6 and a position sensor 7; the first driving The motor 2 is arranged on the frame 1 , the paper roll 3 is connected to the first driving motor 2 ; the static roller 4 is arranged on the frame 1 . The power unit 5 is fixedly arranged on the frame 1, the moving roller 6 is connected with the power unit 5, the reel 3, the static roller 4 and the movable roller 6 are all arranged at intervals, and the belt body 301 protruding from the reel 3 , around the outside of the static roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com