Preparation method of solar microbattery based on random mesh carbon nanotube film

A technology of solar micro-battery and carbon nanotube thin film, which is applied in the manufacture of circuits, electrical components, and final products, etc., can solve the problems of complicated structure manufacturing process, unfavorable long-term stability of solar cell structure, etc., and achieves easy mass production and structure. Simple structure and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

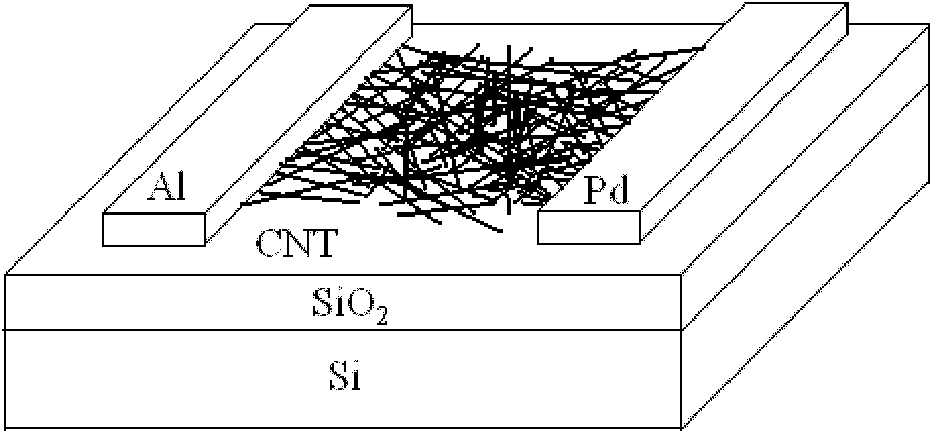

[0028] In this example, a self-assembly method is used to prepare a disordered network single-walled carbon nanotube film, and a disordered networked semiconducting single-walled carbon nanotube film is obtained by using a methane plasma etching method. A pair of symmetrical metal electrodes constitutes an asymmetric solar micro battery.

[0029] Soak the cleaned silicon wafer with a silicon dioxide layer on the surface in H 2 SO 4 and H 2 o 2 The surface of the silicon wafer is made hydrophilic in the mixed solution, where H 2 SO 4 and H 2 o 2 The ratio range is 2:1, the soaking time is 10 hours, and the soaking temperature is 80 degrees; then the silicon wafer cleaned by deionized water is soaked in the APS solution, so that the single-layer APS is modified to a hydrophilic carbon dioxide Silicon surface, immersion time is 10h, H in APS solution 2 The ratio range of O and APS is 100:1; then the silicon wafers cleaned with deionized water and dried are placed in a sus...

Embodiment 2

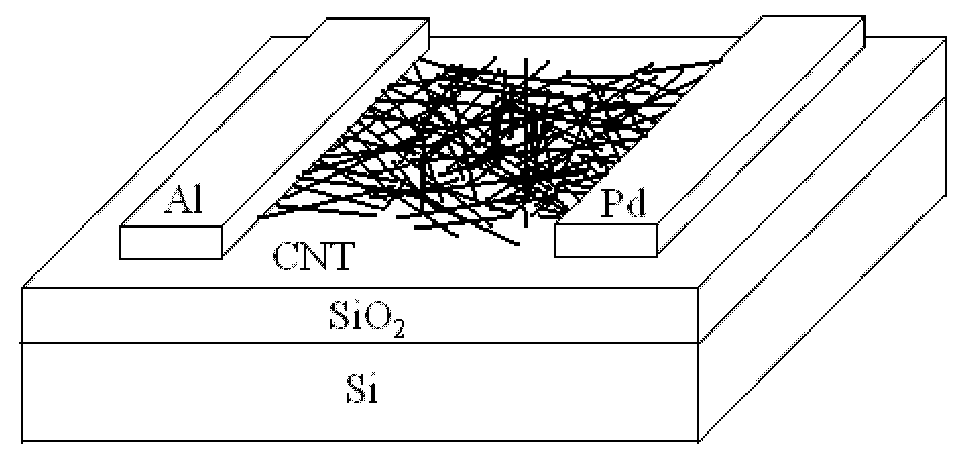

[0033] In this example, a self-assembly method is used to prepare a disordered network single-walled carbon nanotube film, and a disordered networked semiconducting single-walled carbon nanotube film is obtained by using a methane plasma etching method. A pair of symmetrical metal electrodes constitutes an asymmetric solar micro battery.

[0034] Soak the cleaned silicon wafer with a silicon dioxide layer on the surface in H 2 SO 4 and H 2 o 2 The surface of the silicon wafer is made hydrophilic in the mixed solution, where H 2 SO 4 and H 2 o 2 The ratio range is 6:1, the soaking time is 24 hours, and the soaking temperature is 100 degrees; then the silicon wafer cleaned by deionized water is soaked in the APS solution so that the single layer of APS is modified to the hydrophilic silica surface , soaking time is 24h, H in APS solution 2 The ratio range of O and APS is 10000:1; then the silicon wafers cleaned with deionized water and dried are placed in a suspension of...

Embodiment 3

[0038] In this example, a self-assembly method is used to prepare a disordered network single-walled carbon nanotube film, and a disordered networked semiconducting single-walled carbon nanotube film is obtained by using a methane plasma etching method. A pair of symmetrical metal electrodes constitutes an asymmetric solar micro battery.

[0039] Soak the cleaned silicon wafer with a silicon dioxide layer on the surface in H 2 SO 4 and H 2 o 2 The surface of the silicon wafer is made hydrophilic in the mixed solution, where H 2 SO 4 and H 2 o 2 The ratio range is 1:1, the soaking time is 2 hours, and the soaking temperature is 20 degrees; then the silicon wafer cleaned by deionized water is soaked in the APS solution so that the single layer of APS is modified to hydrophilic silica Surface, immersion time is 2h, H in APS solution 2 The ratio range of O and APS is 20:1; then the silicon wafers cleaned with deionized water and dried are placed in a suspension of single-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com