Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of short battery life, difficulty in large-scale production, and low photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

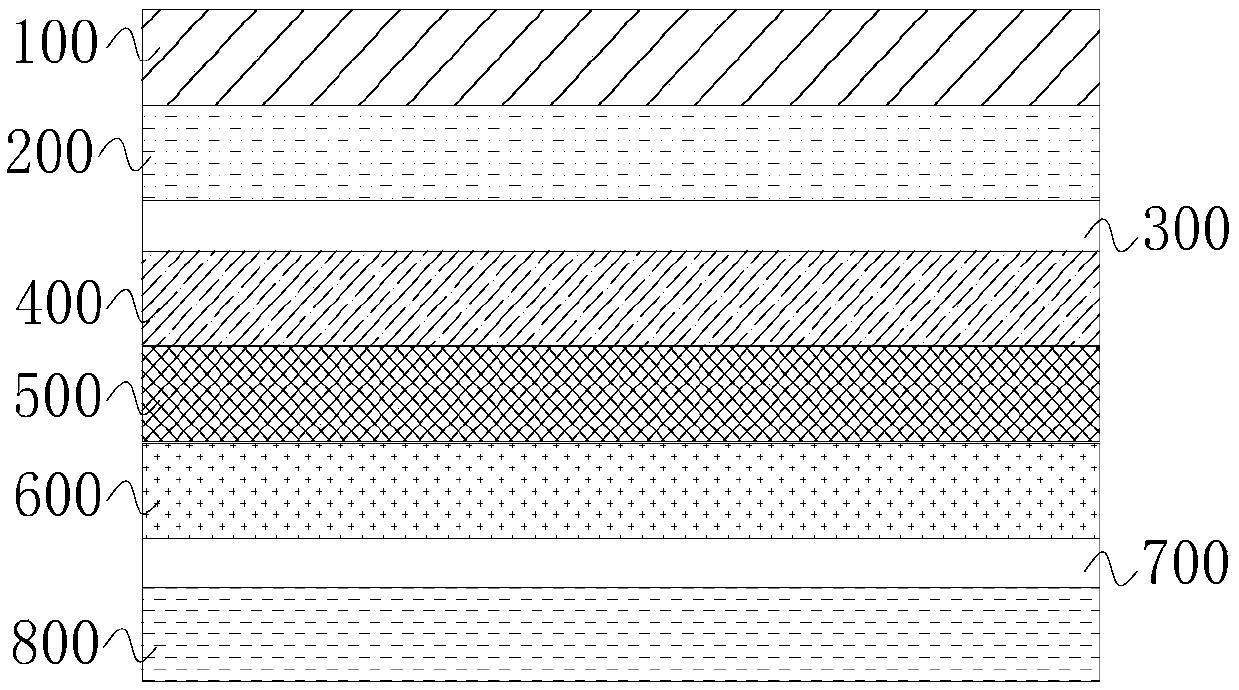

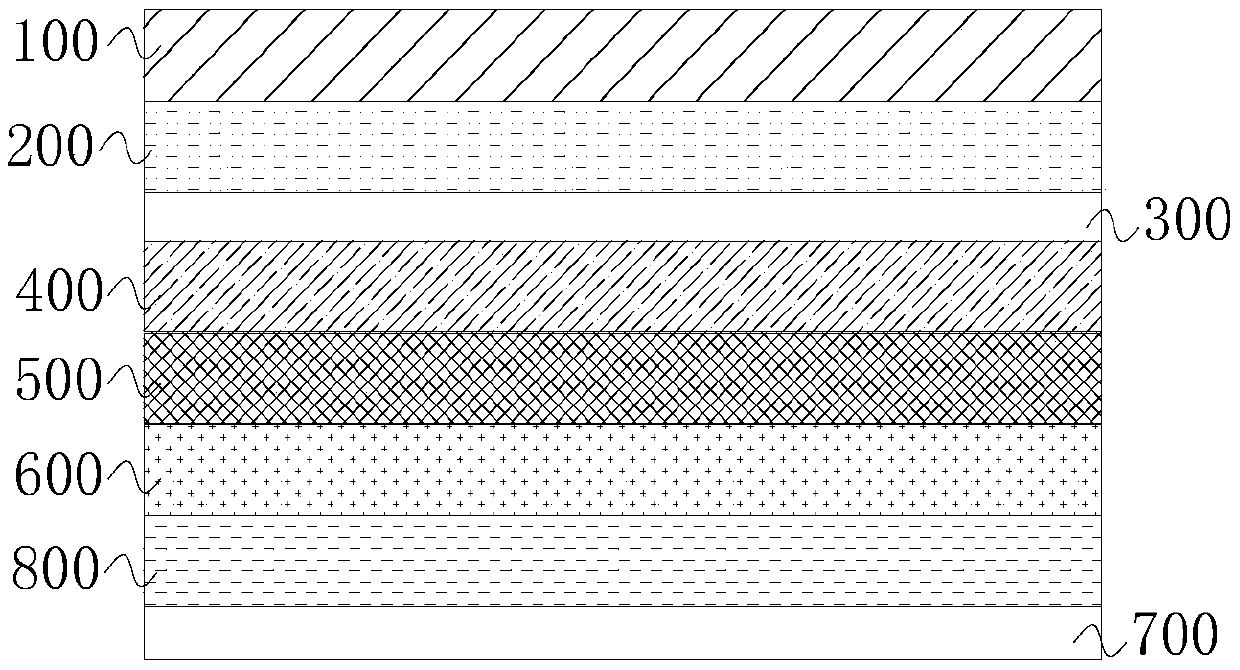

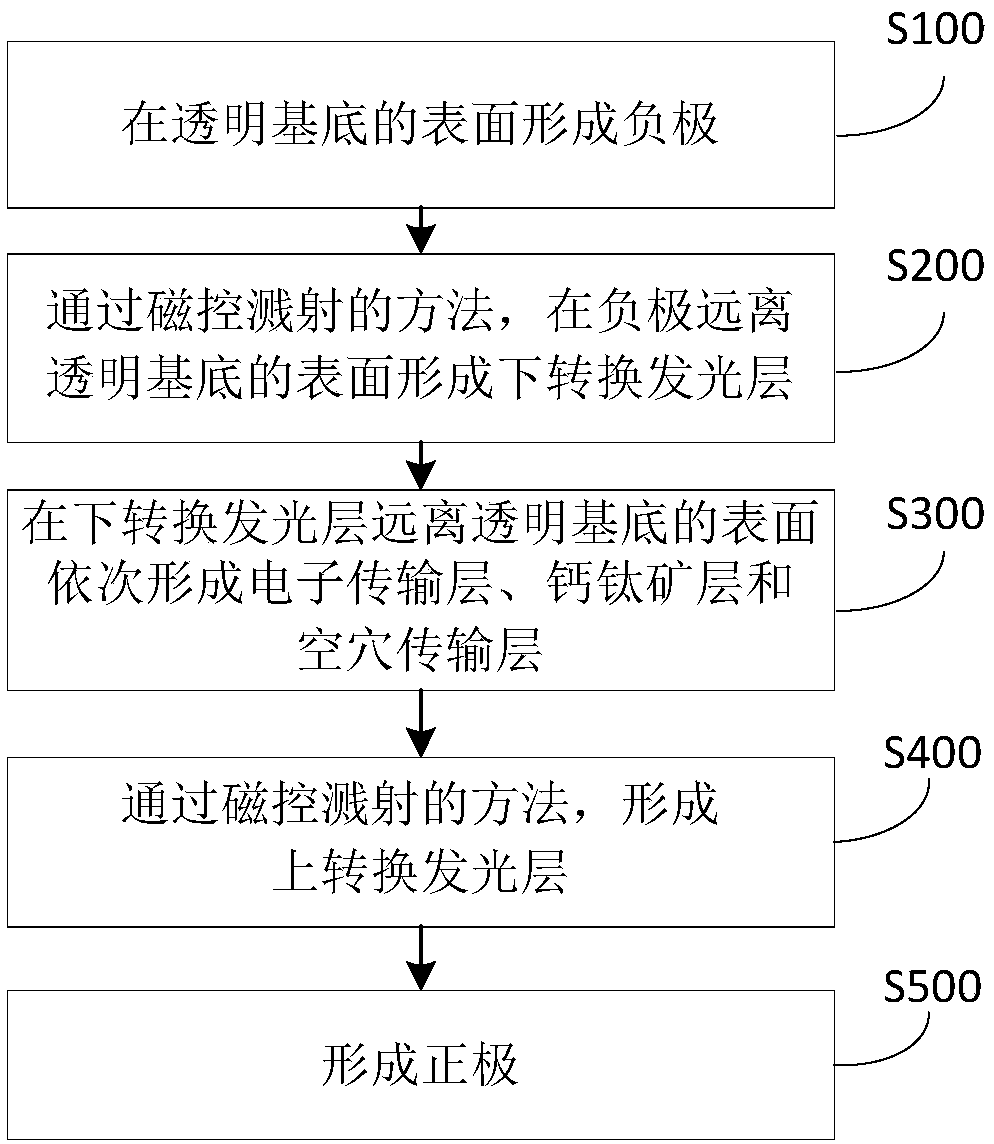

[0058] In one aspect of the invention, the invention proposes a method for preparing a perovskite solar cell. According to an embodiment of the present invention, refer to image 3 , the preparation method comprises:

[0059] S100: forming a negative electrode on the surface of the transparent substrate.

[0060] In this step, the negative electrode 200 is formed on the surface of the transparent substrate 100 . According to the embodiment of the present invention, the specific method for forming the negative electrode 200 is not limited, and those skilled in the art can make a corresponding selection according to the specific raw materials for forming the negative electrode 200 .

[0061] In some embodiments of the present invention, the raw material for forming the negative electrode 200 may include at least one of carbon nanotubes and metal nanowires, then step S100 may include: spraying the suspension containing the raw material for the negative electrode 200 and the sol...

Embodiment 1

[0084] In this example, a perovskite solar cell was fabricated. The specific steps are as follows: (1) Spray the suspension formed by carbon nanotubes and ethanol with a content of 0.1wt% onto a glass substrate heated at 80° C. with a spray gun, and form a layer on the glass surface after the ethanol volatilizes. Layer carbon nanotube transparent network electrode; (2) utilize magnetron sputtering method to sputter and dope 1mol% Er on the electrode surface again 3+ Ca 0.7 Sr 0.3 SiO 4 , the thickness of the sputtering is 50nm; (3) then the electron transport layer, the perovskite layer and the hole transport layer are sequentially prepared by the evaporation method; (4) the gold (Au) electrode of sputtering 300nm; (5) finally, in The surface of the gold electrode was sputtered with 2mol% Ho 3+ NaYF 4 , the thickness of sputtering is 60nm, and a perovskite solar cell with frequency domain conversion material can be obtained.

Embodiment 2

[0086] In this example, a perovskite solar cell was fabricated. Concrete steps are as follows: (1) form suspension liquid with the silver nanowire and ethanol that diameter is 50nm, length is 25 microns, and wherein, the content of silver nanowire is 0.5wt%, and the suspension liquid is sprayed to 80 ℃ heating with spray gun On the glass substrate, a layer of silver nanowire transparent network electrode is formed on the glass surface after the ethanol volatilizes; (2) use magnetron sputtering method to sputter and dope 1.5mol% Mn on the electrode surface 2+ Na 3 YSi 2 o 7 , the thickness of sputtering de1 is 30nm; (3) then adopt the evaporation method to sequentially prepare electron transport layer, perovskite layer and hole transport layer; (4) sputter 300nm silver (Ag) electrode; (4) finally, in The surface of the silver electrode is sputtered with 1.6mol% Gd 3+ NaY(WO 4 ) 2 , the thickness of sputtering is 50nm, and a perovskite solar cell with frequency domain conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com