Coconut de-greening device and method

A technology for de-greening and coconut, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of low de-greening efficiency and inability to continuously de-green, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

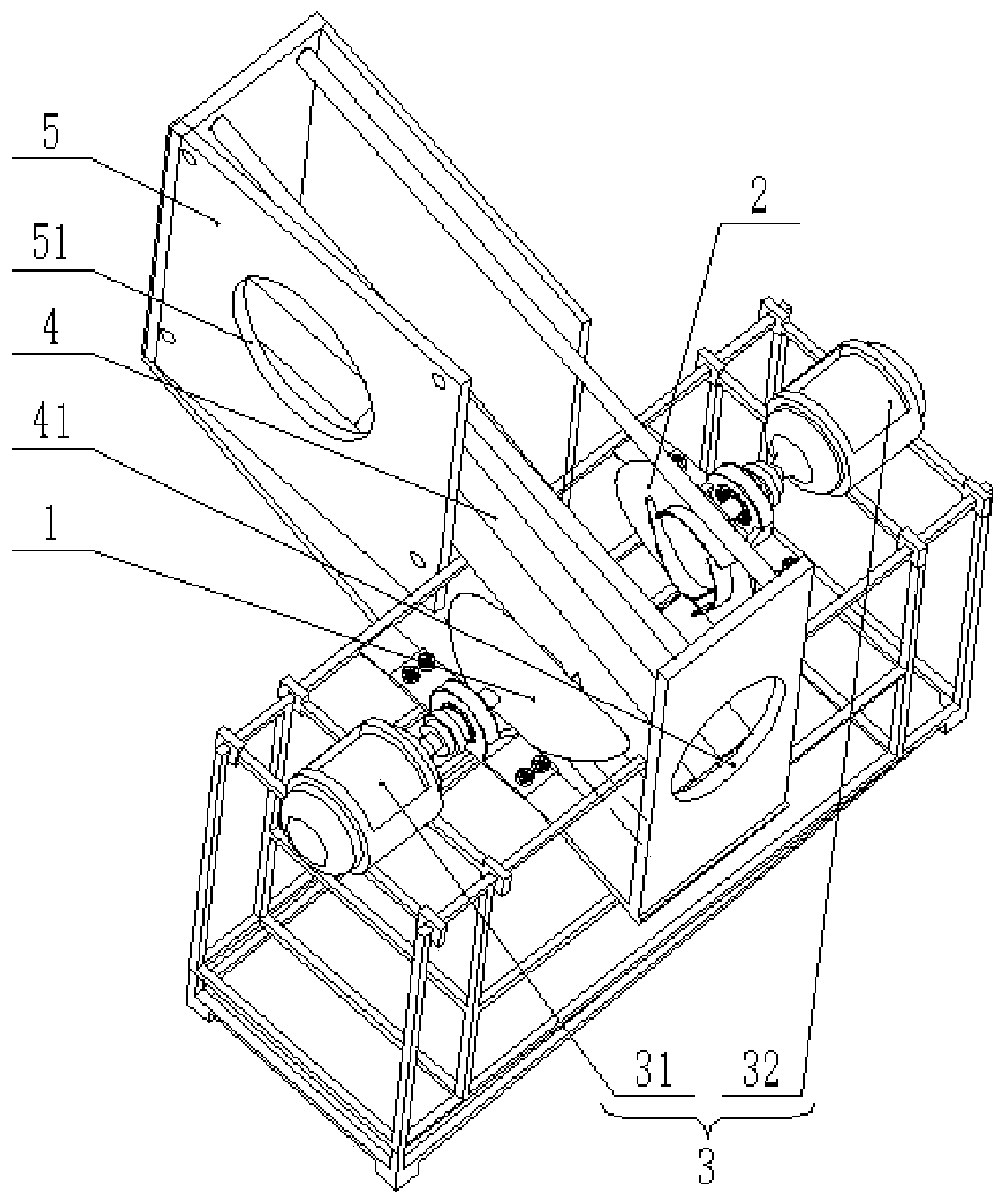

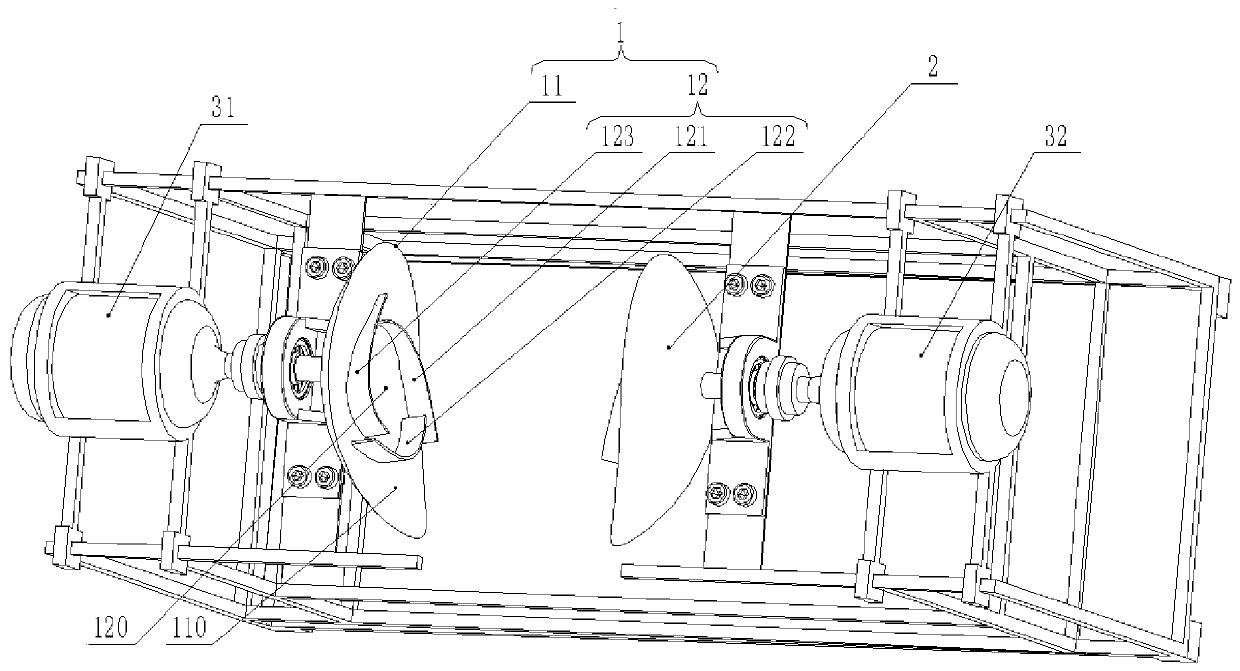

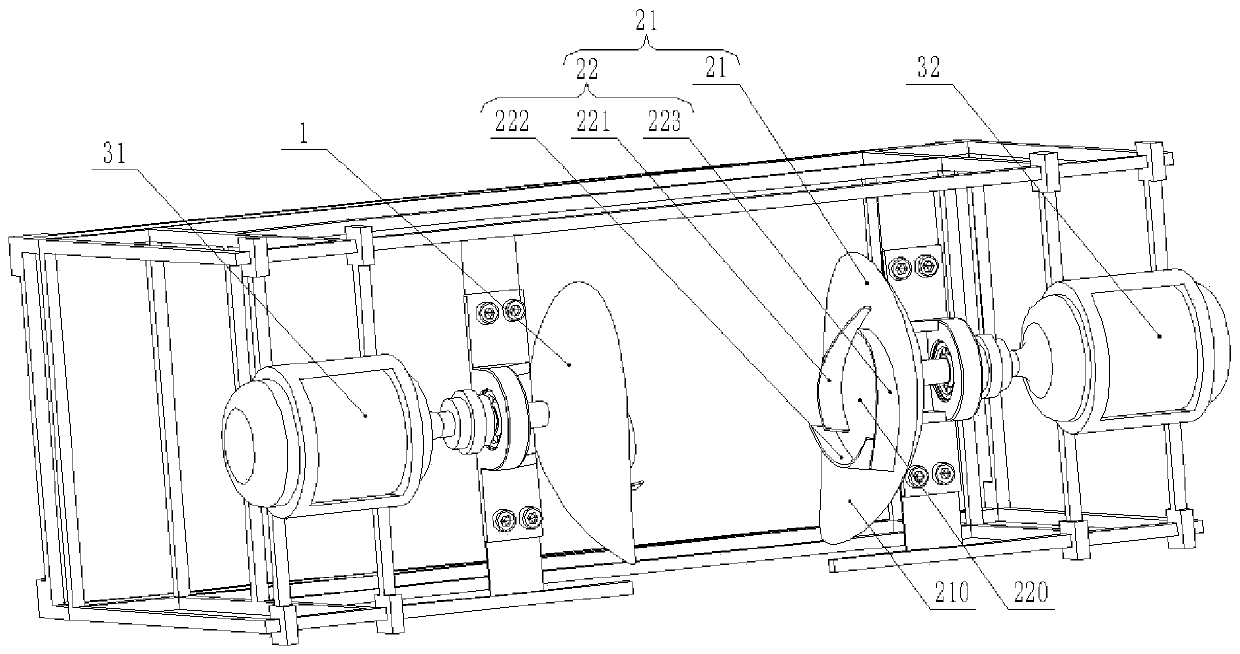

[0028] Such as figure 1 with Figure 4 As shown, the coconut degreening device provided by the embodiment of the present invention includes: a first cutting assembly 1, a second cutting assembly 2 and a driving assembly 3; a cutting opening 101 is formed between the first cutting assembly 1 and the second cutting assembly 2; The driving assembly 3 is transmission-connected to the first cutting assembly 1 and / or the second cutting assembly 2, the driving assembly 3 is used to make the first cutting assembly 1 and the second cutting assembly 2 produce relative rotation, and the opening of the cutting opening 101 changes periodically .

[0029] In some embodiments, the first cutting assembly 1 is fixed on the frame, the second cutting assembly 2 is rotatably connected to the frame, and the drive assembly 3 is in transmission connection with the second cutting assembly 2; or, the second cutting assembly 2 is fixed on the frame , the first cutting assembly 1 is rotatably connecte...

Embodiment 2

[0049] Such as figure 1 , figure 2 with image 3 As shown, the deblueing method provided by the embodiment of the present invention includes: rotating the first cutting assembly 1 relative to the second cutting assembly 2, and making the opening of the cutting opening 101 between the first cutting assembly 1 and the second cutting assembly 2 The degree changes periodically; when the opening of the cutting opening 101 toward the first direction side increases enough to accommodate the object to be deblued, the object to be deblued is placed in the cutting opening 101 from the first direction; when the cutting opening 101 faces the first direction When the opening of the side of the two directions is increased enough to accommodate the object to be decyanized, the object to be decyanized in the cutting opening 101 is discharged along the second direction.

[0050] Using the coconut degreening device provided in Embodiment 1, the first cutting assembly 1 is driven by the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com