Fine milling cutting force simulation predicting method considering tool runout influence

A technology of micro-milling and cutting force, which is applied in the direction of metal processing equipment, metal processing machinery parts, milling machine equipment, etc., and can solve the problems of low prediction accuracy and ignoring the bottom cutting edge effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

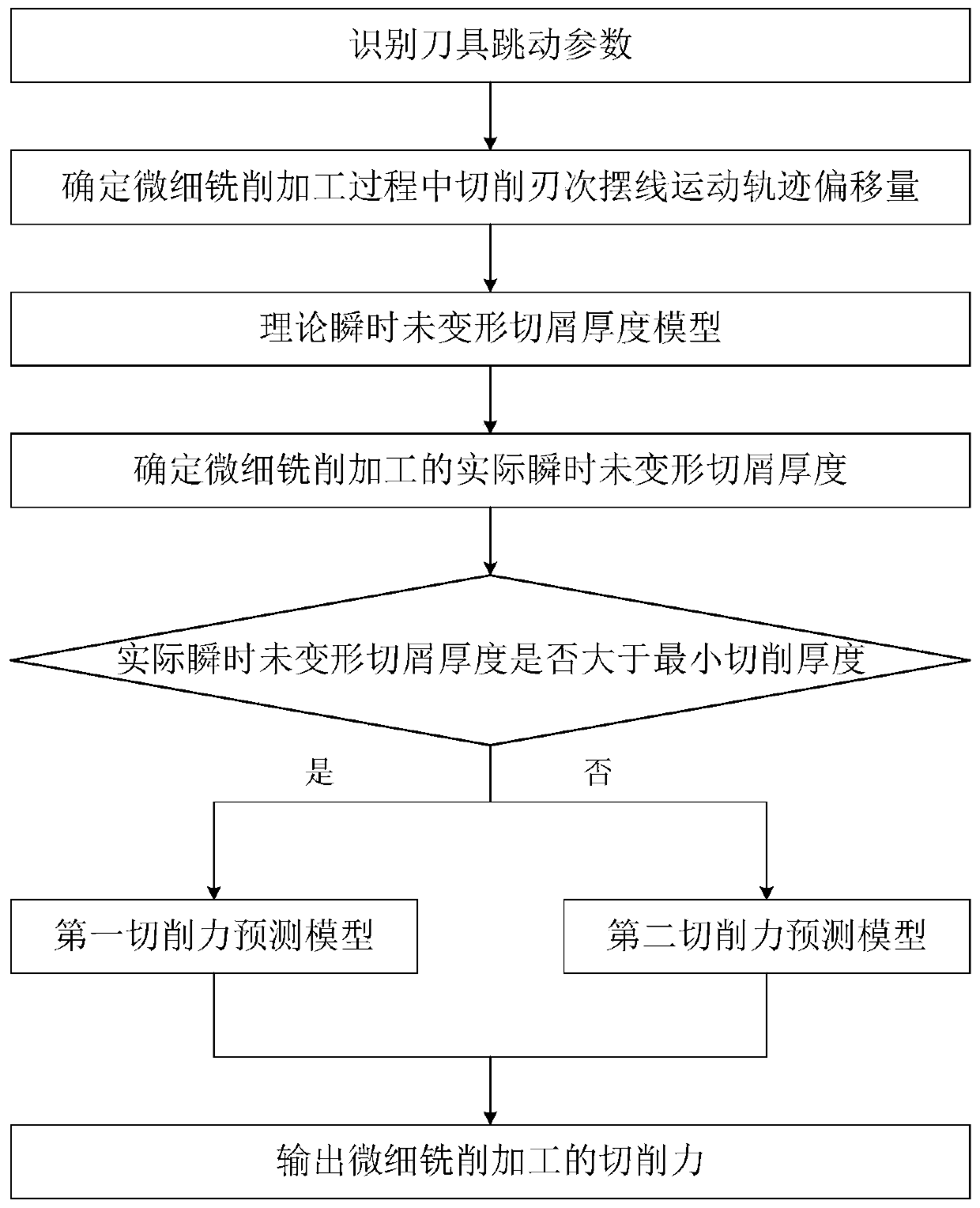

[0082] The present invention provides a method for simulating and predicting the cutting force of micro-milling processing considering the impact of tool run-out for flat end mills, such as figure 1 shown, including the following steps:

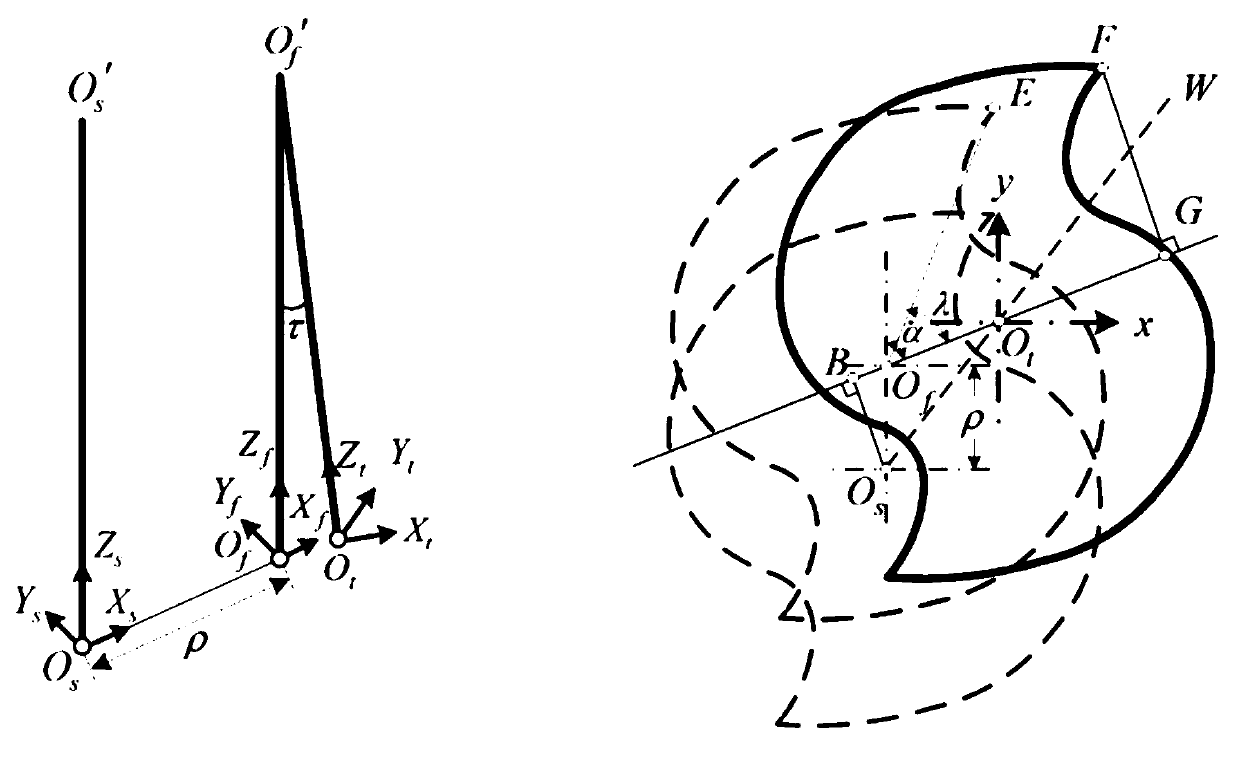

[0083] Step S1, identify the preset tool runout parameters, and determine the cutting edge trochoidal trajectory offset during the micromilling process according to the tool runout parameters; the tool runout parameters are based on the tool diameter during the micromilling process The spatial geometric relationship of runout and tool tilt runout is determined.

[0084] Micro-milling tool runout is defined as the inclination phenomenon between the tool axis and the machine tool fixture and spindle system axis, that is, the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com