Automatic production line for cup bodies of vacuum cups (kettles)

A technology for automated production lines and thermos cups, which can be applied to other manufacturing equipment/tools, manufacturing tools, etc., and can solve the problems of low production efficiency, increased labor operating costs and material management costs, and low processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

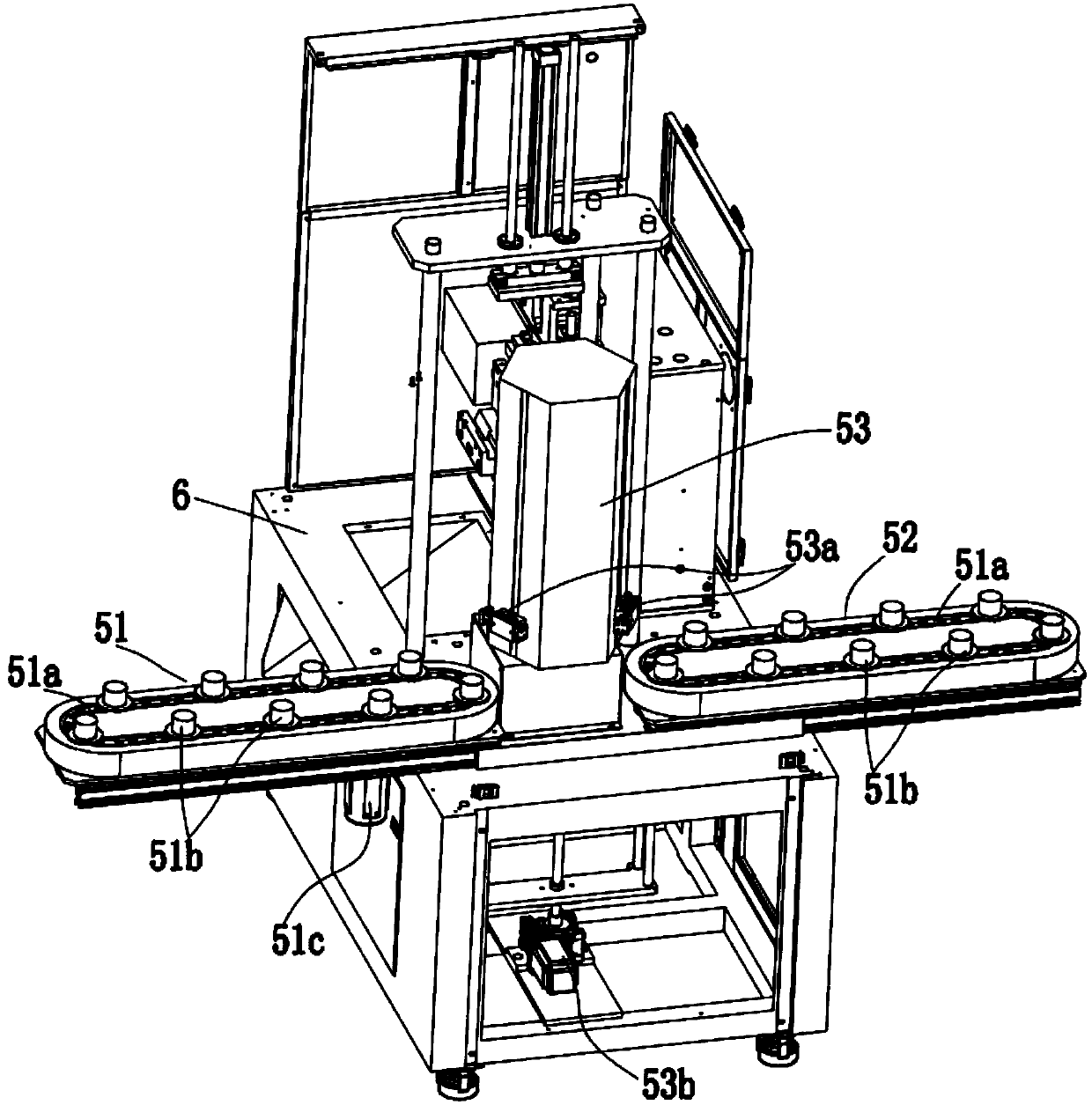

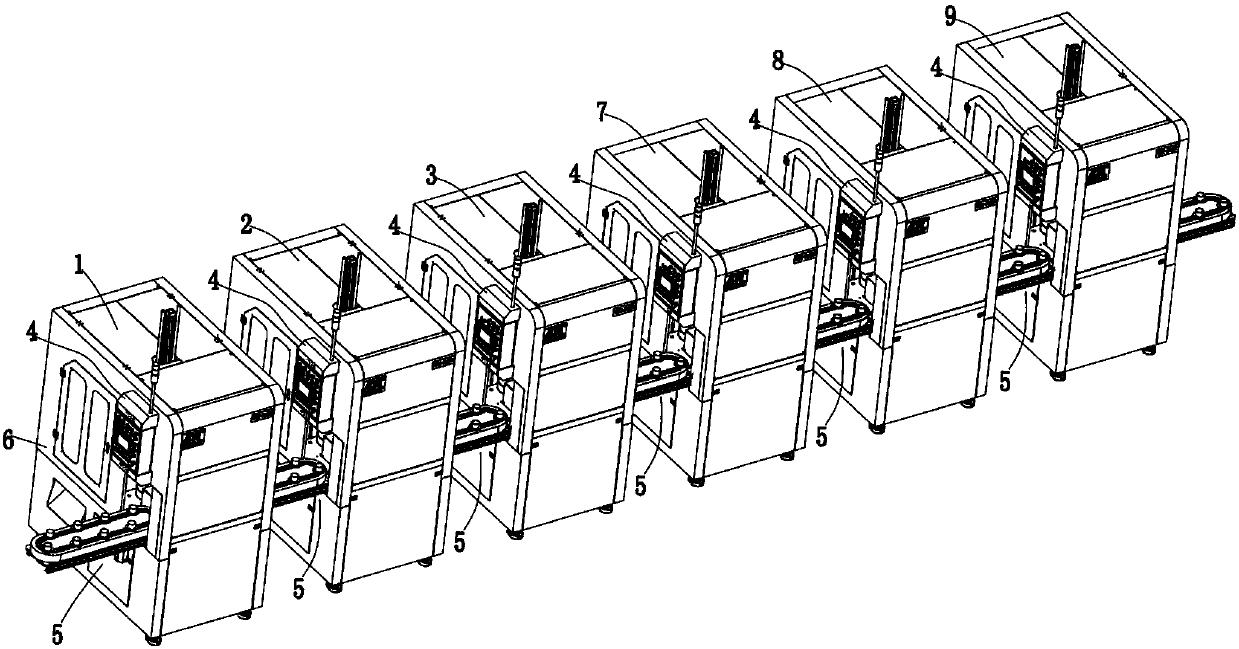

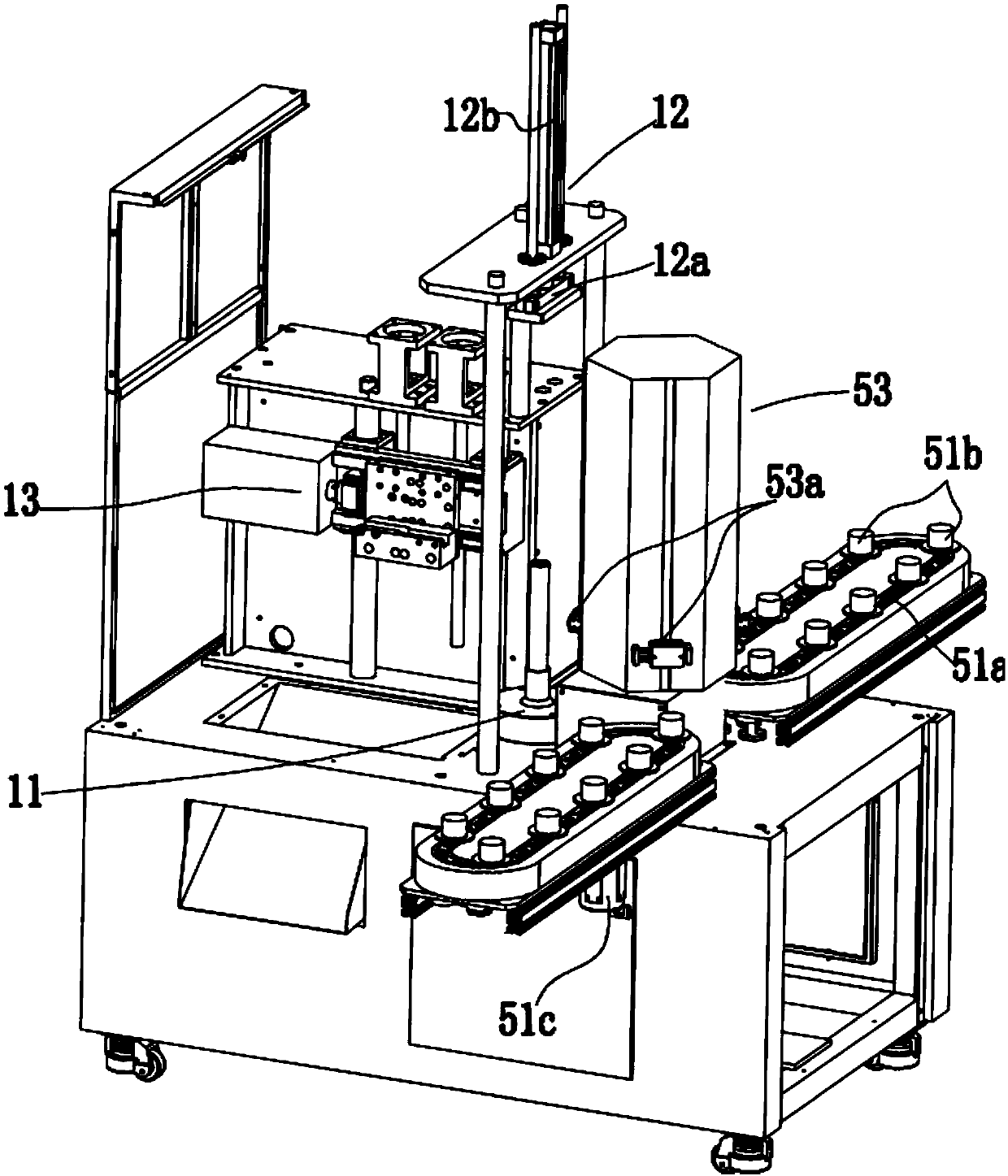

[0019] Such as figure 1 As shown, the thermos cup (pot) cup automatic production line includes a cutting device 1, a whole mouth and a bottom device 2, a rolling upper and lower corner device 3, a control device 4, a transmission device 5 and a frame 6, and the cutting device 1 , whole mouth and whole bottom device 2, rolling upper and lower corner device 3, control device 4, transmission device 5 are arranged on the frame 6, and described cutting mouth device 1, whole mouth and whole bottom device 2, rolling upper and lower corner device 3, transmission device 5 is electrically connected with the control device 4, and the incision device 1, the whole mouth and bottom device 2, and the rolling upper and lower corner devices 3 are all connected through the transmission device 5;

[0020] The conveying device 5 includes an input device 51, an output device 52 and a grabbing device 53;

[0021] The grabbing device 53 is arranged between the input device 51 and the output device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com