Convenient-to-use clamping device for numerically-controlled machine tool

A technology of clamping device and numerical control machine tool, which is applied in the direction of positioning device, clamping, metal processing machinery parts, etc., can solve the problems of troublesome use, time-consuming and labor-intensive work, workpiece turnover, etc., and achieve the advantages of convenient use, easy manufacturing and time saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

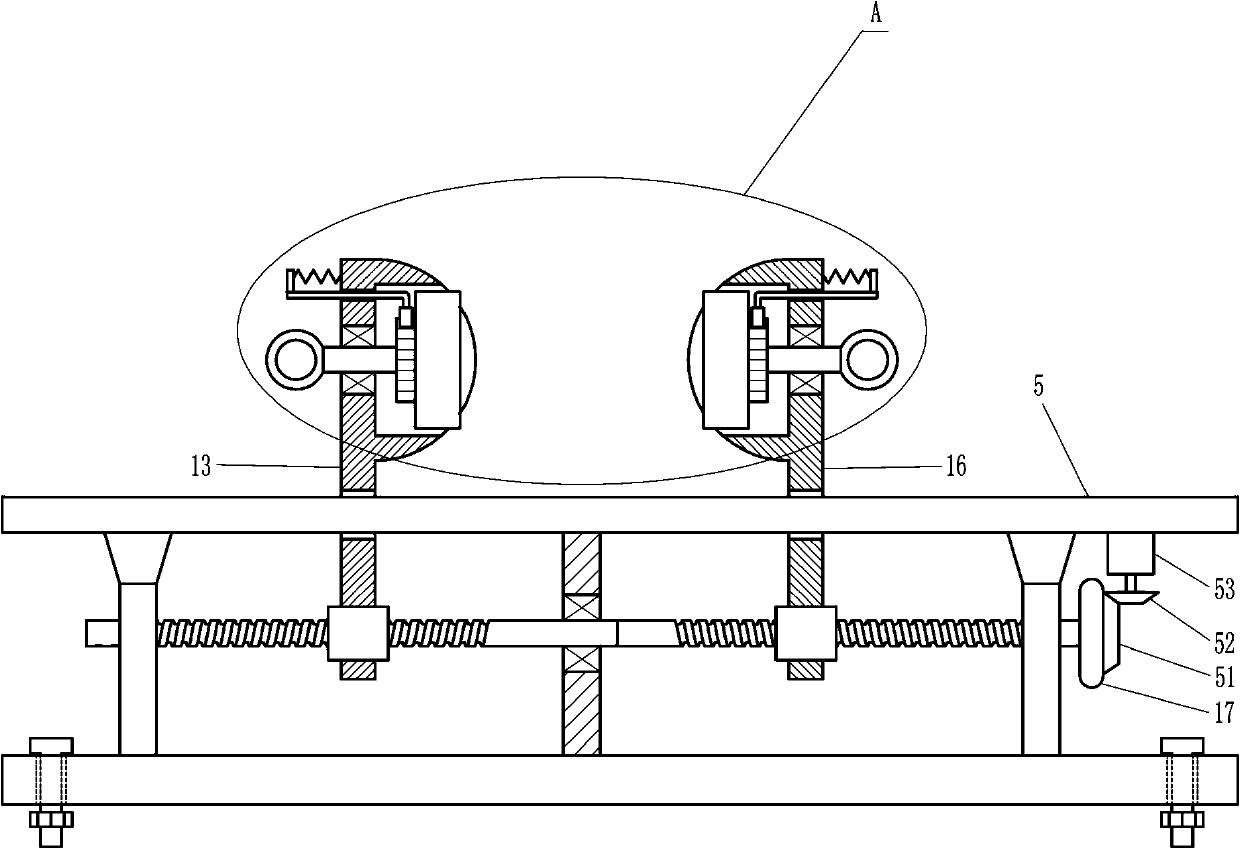

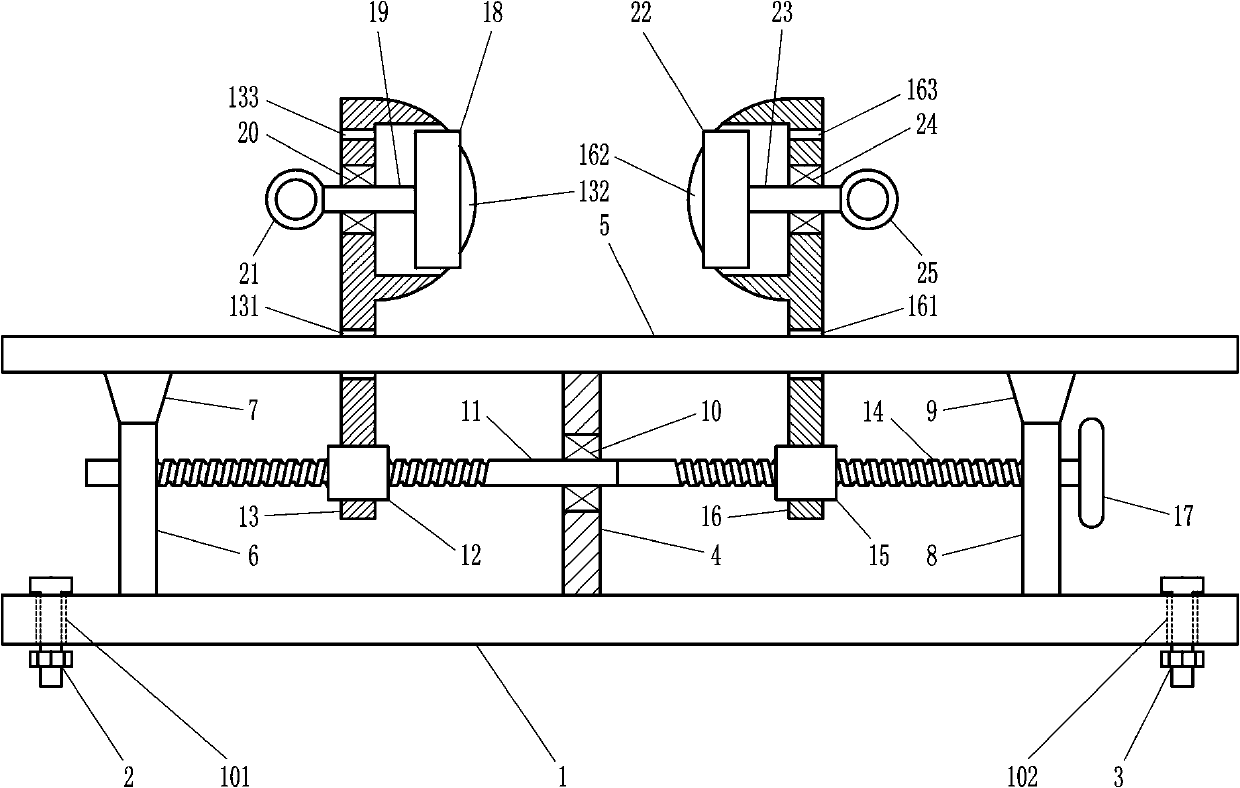

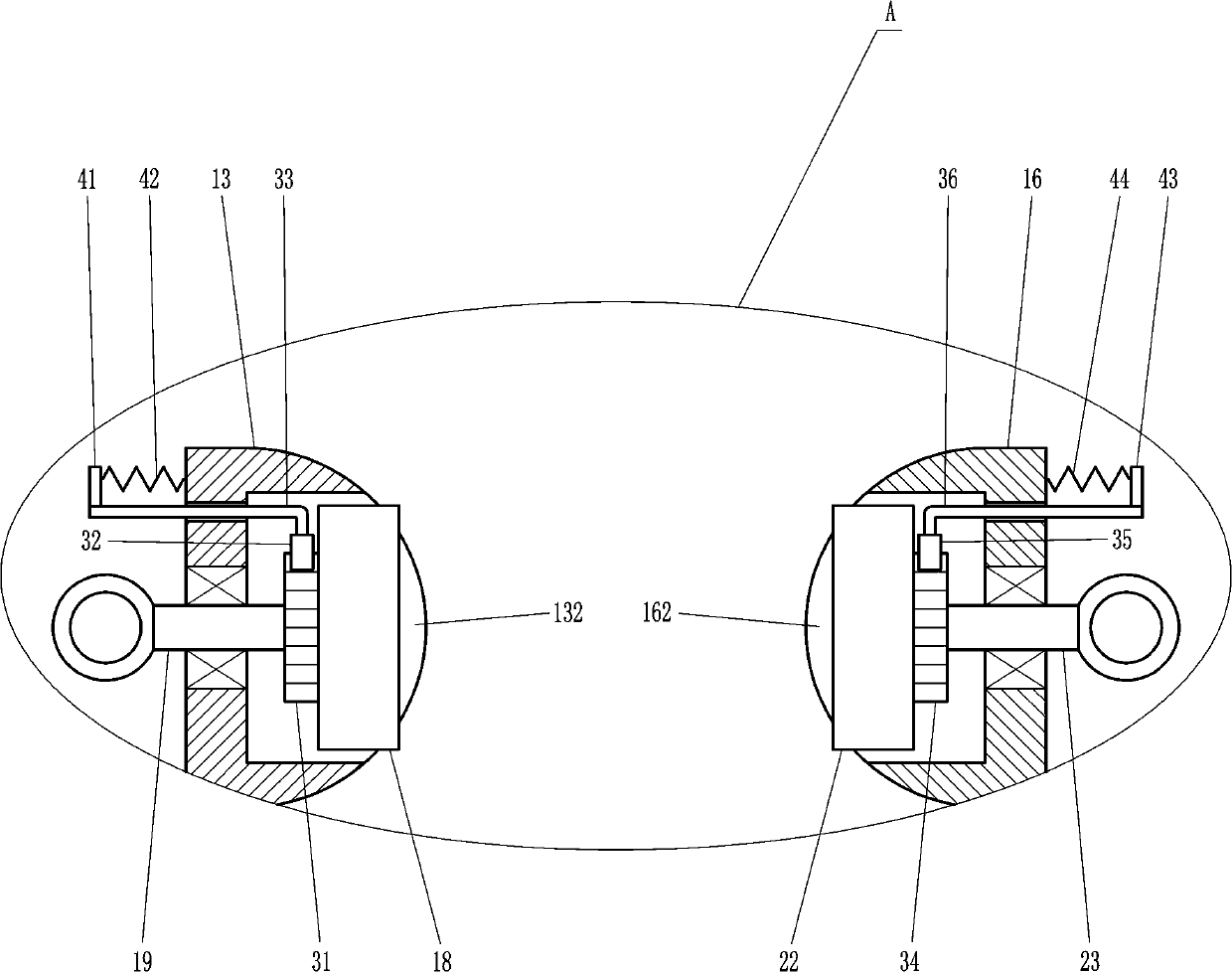

[0019] An easy-to-use clamping device for CNC machine tools such as Figure 1-3As shown, it includes base 1, first large bolt 2, second large bolt 3, large support plate 4, large guide rod 5, first bearing seat 6, first inverted trapezoidal block 7, second bearing seat 8, the first Two inverted trapezoidal blocks 9, the first large bearing 10, the first large screw mandrel 11, the first large nut 12, the first large P-shaped plate 13, the second large screw rod 14, the second large nut 15, the second large P Shaped plate 16, rotating wheel 17, the first pressing plate 18, the first rotating shaft 19, the second large bearing 20, the first grab ring 21, the second pressing plate 22, the second rotating shaft 23, the third large bearing 24 and the second Grab ring 25, the left end of the base 1 has a first large through hole 101, the first large bolt 2 is located in the first large through hole 101, the right end of the base 1 has a second large through hole 102, and the second ...

Embodiment 2

[0021] An easy-to-use clamping device for CNC machine tools such as Figure 1-3 As shown, it includes base 1, first large bolt 2, second large bolt 3, large support plate 4, large guide rod 5, first bearing seat 6, first inverted trapezoidal block 7, second bearing seat 8, the first Two inverted trapezoidal blocks 9, the first large bearing 10, the first large screw mandrel 11, the first large nut 12, the first large P-shaped plate 13, the second large screw rod 14, the second large nut 15, the second large P Shaped plate 16, rotating wheel 17, the first pressing plate 18, the first rotating shaft 19, the second large bearing 20, the first grab ring 21, the second pressing plate 22, the second rotating shaft 23, the third large bearing 24 and the second Grab ring 25, the left end of the base 1 has a first large through hole 101, the first large bolt 2 is located in the first large through hole 101, the right end of the base 1 has a second large through hole 102, and the second...

Embodiment 3

[0024] An easy-to-use clamping device for CNC machine tools such as Figure 1-3As shown, it includes base 1, first large bolt 2, second large bolt 3, large support plate 4, large guide rod 5, first bearing seat 6, first inverted trapezoidal block 7, second bearing seat 8, the first Two inverted trapezoidal blocks 9, the first large bearing 10, the first large screw mandrel 11, the first large nut 12, the first large P-shaped plate 13, the second large screw rod 14, the second large nut 15, the second large P Shaped plate 16, rotating wheel 17, the first pressing plate 18, the first rotating shaft 19, the second large bearing 20, the first grab ring 21, the second pressing plate 22, the second rotating shaft 23, the third large bearing 24 and the second Grab ring 25, the left end of the base 1 has a first large through hole 101, the first large bolt 2 is located in the first large through hole 101, the right end of the base 1 has a second large through hole 102, and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com