Preparation method and application of a yellow fluorescent bioimaging material

A biological imaging and yellow fluorescence technology, which is applied to luminescent materials, material analysis through optical means, and analysis of materials, can solve the problems of poor repetition rate and complex synthesis operation methods, and achieve high fluorescence efficiency and good photobleaching resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

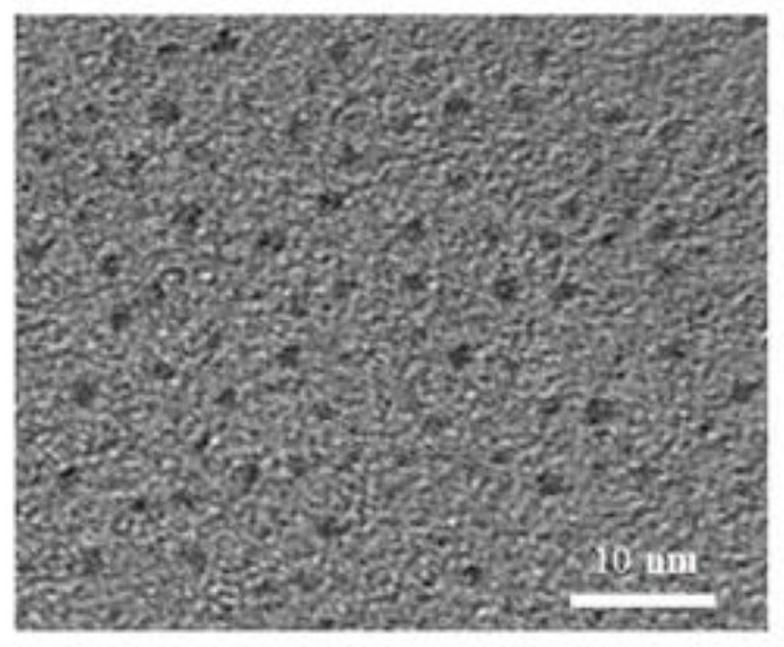

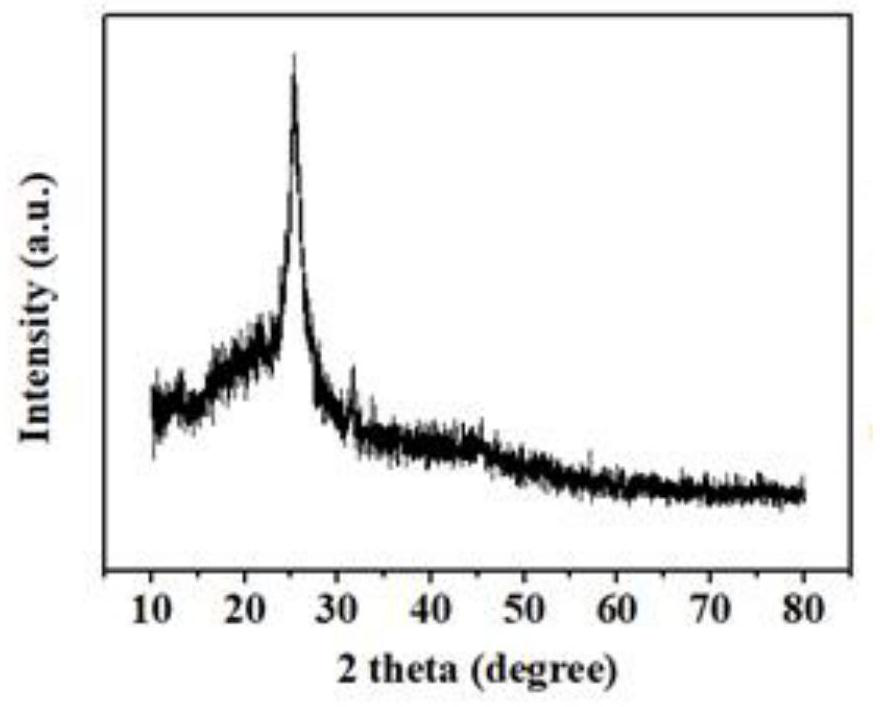

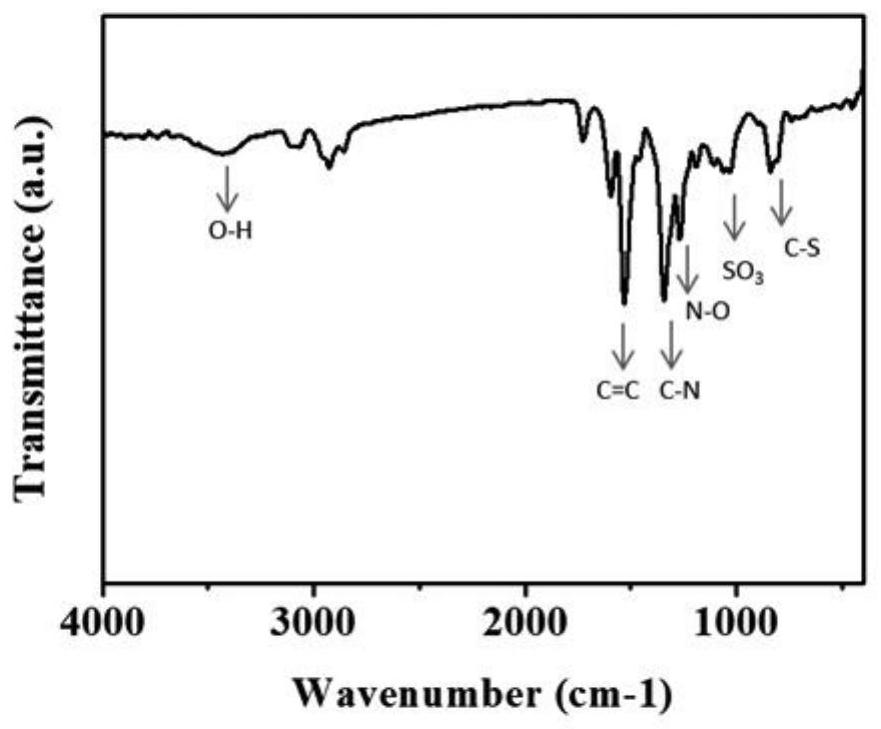

Image

Examples

Embodiment 1

[0060] A schematic embodiment of the present invention, a method of preparing a yellow fluorescent biomaraminated material, comprising the steps of:

[0061] Step S1: Preparation of yellow fluorescence biomara

[0062] Step S11: Weighing 4 g of phenanthemum, slowly adding the phenanthemone into the concentrated nitric acid, stirred while stirring, after refluxing at a temperature of 80 ° C, cooling;

[0063] Step S12: The solution obtained by preparing to step S11 is added to the excess deionized water, and the filtration washing until pH is neutral, drying to obtain 1,3,6-trinitrofrofromin;

[0064] Step S13: 0.1 g of 1,3,6-trinitr-nitroflyrene and sodium sulfite is weighed, and then dissolved in 40 ml of ethanol, then transferred to polytetrafluoroethylene, at 200 ° C for 12h;

[0065] Step S14: The resulting solution was filtered through the 0.22 μm filter, and the unreacted particles were removed, and the crude product was obtained;

[0066] Step S2: The yellow fluorescent bio...

Embodiment 2

[0074] Another embodiment of the present invention, a method of preparing a yellow fluorescent biomaraminated material, comprising the steps of:

[0075] Step S1: Preparation of yellow fluorescence biomara

[0076] Step S11: 2 g of a pyrene, slowly add the phenanthemone in a 150 ml of concentrated nitric acid, stir, while stirring, after 24 h at a certain 60 ° C temperature, cool;

[0077] Step S12: The solution obtained by preparing to step S11 is added to the excess deionized water, and the filtration washing until pH is neutral, drying to obtain 1,3,6-trinitrofrofromin;

[0078] Step S13: Weighing 1,3,6-trinitr-nitroflyfoxy and sodium sulfite each, 0.05 g of sulfite, dissolved in 20 ml of ethanol, then transferred to polytetrafluoroethylene, at 180 ° C for 6 h;

[0079] Step S14: Filtering the solution obtained by step S13 using a 0.20 μm filter film, removes unreacted particles to obtain a crude product;

[0080] Step S2: The yellow fluorescent biological imaging material prep...

Embodiment 3

[0088] Another embodiment of the present invention, a method of preparing a yellow fluorescent biomaraminated material, comprising the steps of:

[0089] Step S1: Preparation of yellow fluorescence biomara

[0090] Step S11: Weigh 6 g of pyrene, slowly add phenanthemone to 450 ml of concentrated nitric acid, stir the binding and stir, after reflowing at a temperature of 100 ° C, cooling;

[0091] Step S12: The solution obtained by preparing to step S11 is added to the excess deionized water, and the filtration washing until pH is neutral, drying to obtain 1,3,6-trinitrofrofromin;

[0092] Step S13: 0.2 g of 1,3,6-trinitr-nitroxyl and sodium sulfite were weighed, and 60 ml of ethanol was dissolved, and then transferred to polytetrafluoroethylene, reacted at 220 ° C for 18 h;

[0093] Step S14: The resulting solution was filtered through the 0.24 μm filter, and the unreacted particles were removed, and the crude product was obtained;

[0094] Step S2: The yellow fluorescent biologic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com